B21, China Town Mall, Midrand

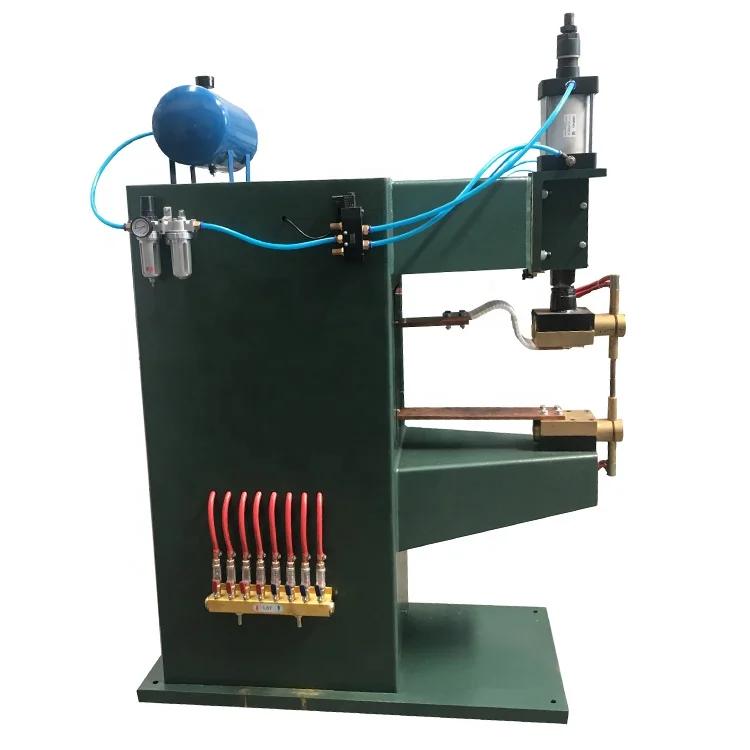

Resistant roll welder automatic seam welding machine

- Section : Machinery

- Category : Welding Equipment

- SKU : 1601043804662

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Resistant Roll Welder Automatic Seam Welding Machine and what is it used for?

This is an automatic resistance roll (seam) welding machine designed to produce continuous welded seams on sheet material. It is commonly used for producing leak-tight seams on tanks, pipes, automotive components, HVAC ducts, and other applications requiring continuous spot/overlap welding.

2. What models are available and how do they differ?

Available models: FN-35, FN-50, FN-75, FN-100, FN-125, FN-160. They differ by welding transformer capacity (KVA), input current, maximum weldable sheet thickness, welding speed range and machine weight. Higher model numbers provide greater KVA, higher input current capability and larger maximum welding thickness.

3. What are the electrical requirements?

The machine is specified for Single Phase 380V, 50Hz input. Input current by model: FN-35: 92A, FN-50: 131A, FN-75: 197A, FN-100: 263A, FN-125: 328A, FN-160: 420A. For installations with different voltages or frequencies, or to confirm supply capacity, consult the manufacturer or your electrical engineer.

4. What maximum sheet thickness can each model weld?

Maximum welding thickness (overlap configuration) by model: FN-35: 1+1 mm, FN-50: 1.5+1.5 mm, FN-75: 2+2 mm, FN-100: 2.5+2.5 mm, FN-125: 3+3 mm, FN-160: 3.5+3.5 mm. Actual capacity can vary with material, surface condition and welding parameters.

5. What welding speed does the machine support?

Welding speed is adjustable in the range 0.8–3.2 m/min. Optimal speed depends on material type/thickness and power settings; perform process trials to set ideal parameters for seam quality.

6. Which materials is this seam welder suitable for?

It is primarily intended for carbon steel, stainless steel and galvanized steel sheet. Non-ferrous materials (aluminum, copper alloys) may be welded in some cases but require careful parameter tuning and typically additional equipment or testing due to different electrical and thermal properties. Always validate on sample parts before production.

7. How heavy is the machine?

Machine weights by model: FN-35: 470 kg, FN-50: 500 kg, FN-75: 620 kg, FN-100: 720 kg, FN-125: 810 kg, FN-160: 930 kg. Allow for additional space and supporting structure when planning installation.

8. What safety features should I expect and what precautions should I take?

Typical safety features include emergency stop, interlocked guards around drive and electrode areas, and electrical protection. Precautions: provide proper grounding, use PPE (welding goggles/face shield, gloves, protective clothing), implement lockout/tagout for maintenance, and ensure ventilation for any fumes. Follow the machine manual and local safety regulations.

9. What consumables and spare parts are required?

Common consumables include welding rollers/electrodes, contact tips, and cooling system components (filters, hoses). Wear parts are the electrode/roller surfaces which must be inspected and dressed or replaced periodically. Keep a small inventory of rollers and contact parts to minimize downtime.

10. What maintenance is required and how often?

Routine maintenance includes cleaning and inspecting rollers and contacts, checking electrical connections and cooling system, lubricating mechanical bearings per schedule, and verifying welding parameters and alignment. Daily visual checks and weekly cleaning plus periodic preventive maintenance (monthly/quarterly) are recommended; follow the manufacturer maintenance manual for exact intervals.

11. How do I choose the right model for my application?

Choose based on the maximum total sheet thickness you need to weld (use the model thickness ratings above), production speed (0.8–3.2 m/min), and power availability. For heavier gauge material or higher throughput choose higher KVA models (FN-100 and above). If unsure, provide sample materials and required production rates to the supplier for recommendation.

12. Is cooling required and how is the machine cooled?

Yes — resistance roll welders generate heat and typically use water cooling for transformer and electrode/roller assemblies. Ensure an adequate chilled water supply or the provided cooling unit per the manufacturer’s specifications to maintain consistent weld quality and prevent overheating.

13. Can this machine produce leak-tight seams for pressure vessels or tanks?

Yes — when properly set up and parameters optimized for material and thickness, roll seam welders can produce continuous, leak-tight seams suitable for some tanks and ducts. Qualification testing (leak tests, destructive/non-destructive examination) is recommended to confirm seam integrity for pressure or fluid containment applications.

14. What commissioning, training, and support are provided?

Most suppliers provide factory acceptance testing, on-site commissioning, operator training, and technical manuals. Extended support, spare parts kits, and preventive maintenance contracts are often available. Confirm the level of after-sales service offered when purchasing.

15. What troubleshooting steps should I take if weld quality is inconsistent?

Check roller/electrode condition and alignment, verify contact resistance and tight electrical connections, confirm consistent material feed and surface cleanliness, inspect cooling and transformer performance, and review welding current/speed parameters. If problems persist, document conditions and contact technical support for parameter recommendations and service.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading