B21, China Town Mall, Midrand

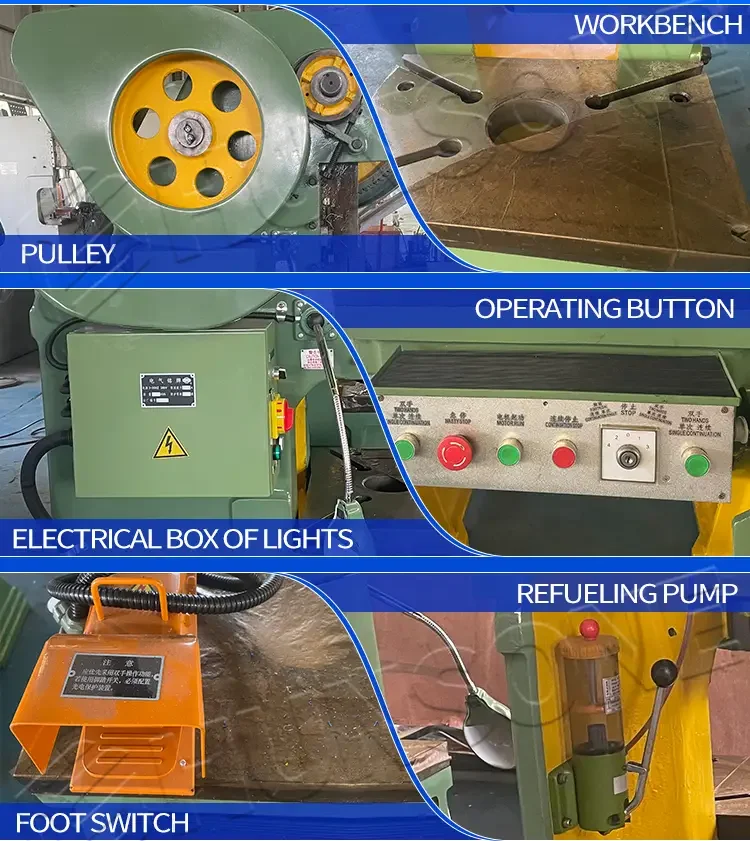

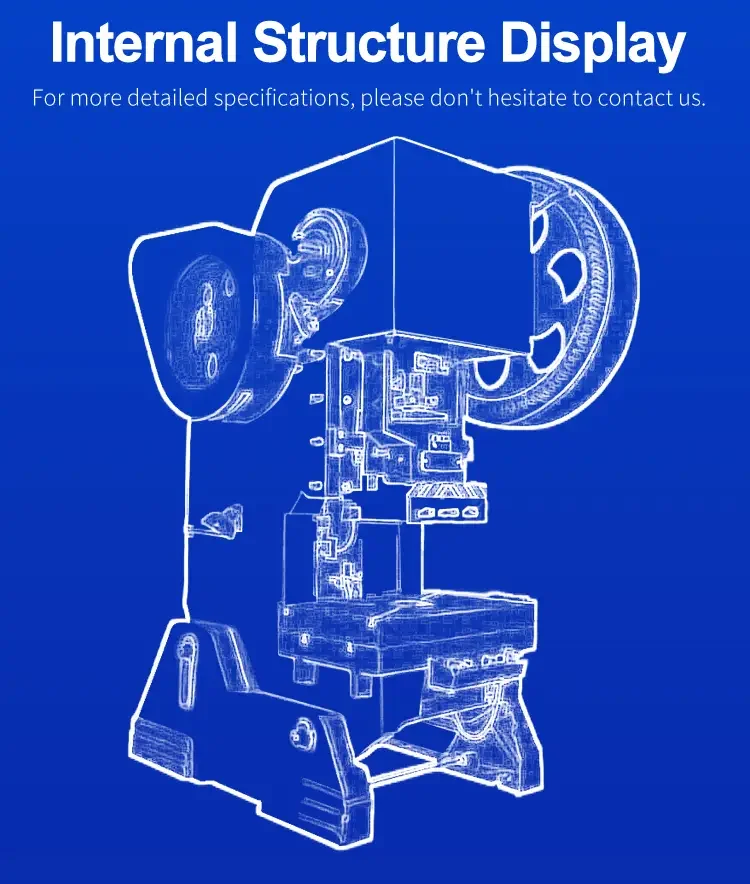

Punching Press Machine- Model J23-6.3

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 1600875987050

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the rated capacity of the Punching Press Machine Model J23-6.3?

The J23-6.3 has a rated punching capacity of 63 kN.

2. What are the main stroke specifications of the J23-6.3?

Nominal stroke is 22 mm and slide stroke length is 35 mm. The machine runs at up to 170 strokes per minute.

3. What size dies and die set heights does the J23-6.3 accept?

Maximum die set height is 150 mm, and die shut height adjustment range is 30 mm. The bolster thickness is 30 mm.

4. What are the bolster and table dimensions on the J23-6.3?

Bolster (L-R x F-B) is 310 x 200 mm with a thickness of 30 mm. Table hole diameter is 60 mm.

5. What is the throat depth and distance between uprights for this model?

Throat depth is 110 mm and the distance between uprights is 150 mm.

6. What is the stem (ram) hole size on the J23-6.3?

Stem hole diameter is 30 mm with a depth of 55 mm.

7. What are the machine's overall dimensions, weight and motor power?

Overall dimensions (L-R x F-B x H) are 620 x 780 x 1503 mm. Motor power is 0.75 kW and the machine weight is approximately 400 kg.

8. What foundation / mounting footprint is required for installation?

Distance between foundation bolts (L-R x F-B) is 314 x 530 mm. Use these values when laying out anchor bolts for installation.

9. Can the J23-6.3 handle angled/inclined punching operations?

Yes — the J23-6.3 supports a maximum inclinable angle of 45°.

10. What materials and thicknesses can this press punch?

The J23-6.3 is designed for sheet metal punching (e.g., carbon steel, stainless, aluminum). Maximum workable thickness depends on material strength, tool geometry and hole perimeter — provide part details for an exact assessment.

11. Is tooling (punches and dies) included or compatible with standard tooling?

Tooling is typically supplied separately. The machine accepts standard punch and die sets compatible with the specified bolster/table dimensions and stem hole; confirm tooling dimensions when ordering.

12. What routine maintenance does the J23-6.3 require?

Regular maintenance includes lubrication of sliding components, checking and tightening fasteners, inspecting punch/die wear, and verifying clutch/brake and safety devices. Follow the manufacturer's maintenance schedule for service intervals.

13. How can I get spare parts, service or configuration help for this model?

Contact the manufacturer or authorized dealer with the model (J23-6.3) and serial number. Provide details on the part or service required; they can supply genuine spare parts, tooling and technical support.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading