B21, China Town Mall, Midrand

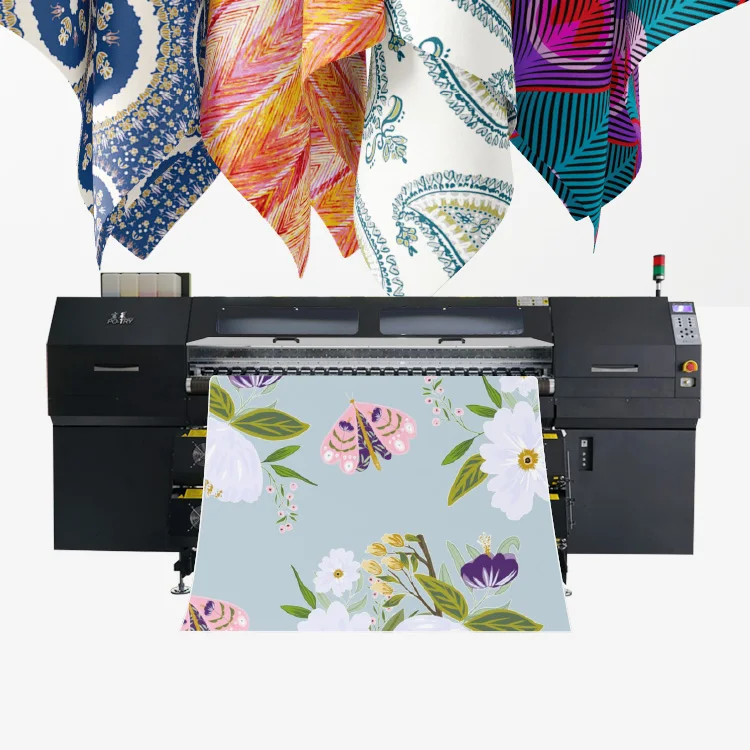

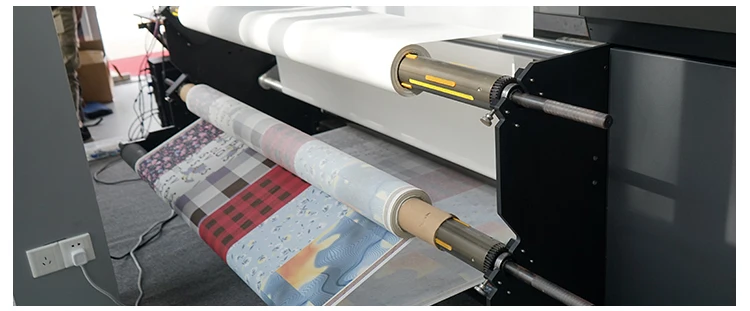

POTRY 1.8m 15 Print Heads Solution Heat Transfer High Speed Textile Machinery Sublimation Printer

- Section : Machinery

- Category : Textile Machinery

- SKU : 1600789102031

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the exact model name of this printer?

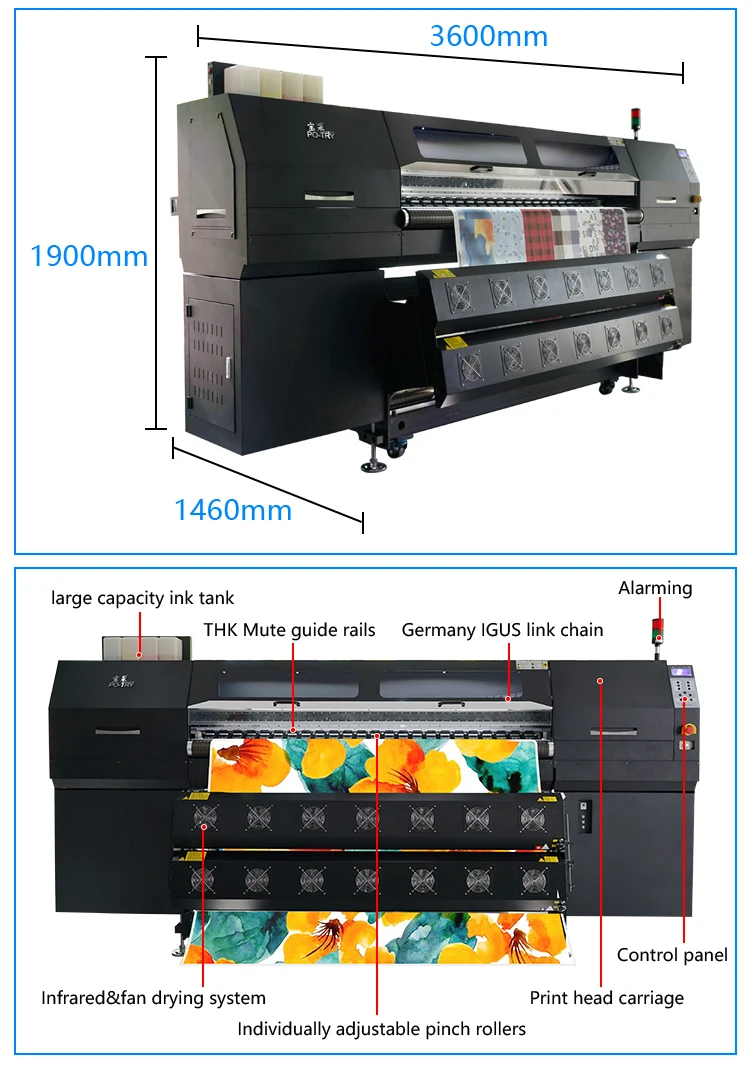

The product is marketed as the POTRY Sublimation Heat Transfer Printer (Model: PO-TRY). The specification sheet also references BC-1915E-HT as a configuration identifier for the 15-print-head variant.

2. What maximum print widths and sizes does this printer support?

The printer is available in multiple widths: 1300 mm, 1800 mm, 1900 mm, 2500 mm and 3200 mm. The specification example lists a 1800 mm print width.

3. What kind of printing system does it use (flatbed or roll-to-roll)?

It is a roll-to-roll sublimation printer with automatic feeding and take-up shafts designed for long media runs, suitable for banners and continuous textile production.

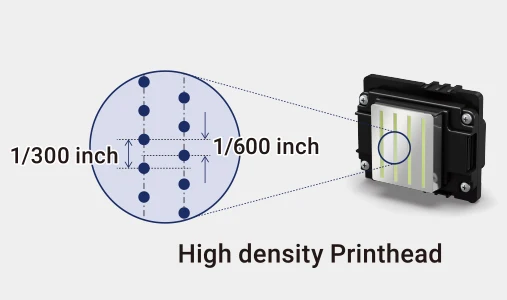

4. What printheads and how many are installed?

The machine is equipped with 15 Epson printheads (Epson I3200-A1), with Epson 4720 as an optional choice depending on configuration.

5. What is the printing speed?

Typical specification lists up to 550 m²/h in a 1-pass high-speed mode and around 310 m²/h in a 2-pass mode for higher quality. Actual throughput will depend on resolution, media and print settings.

6. Which inks does the printer use and what is the ink capacity?

The printer uses sublimation inks and features a large-capacity ink system of 4 × 2 L (four-color CMYK), allowing longer unattended runs between refills.

7. What media can I print on with this sublimation printer?

This printer is designed for sublimation paper intended for dye-sublimation transfer. After printing on sublimation paper, designs are transferred to polyester textiles or sublimation-coated substrates using a heat press or rotary heat transfer system.

8. Does the printer include RIP software and what features does it support?

Yes — the printer ships with Maintop RIP software. The RIP provides layout, color management and print workflow control. It supports standard image file workflows and ICC-based color management (for exact supported file types, check the software documentation).

9. How does the printer protect printhead life and ensure stable ink delivery?

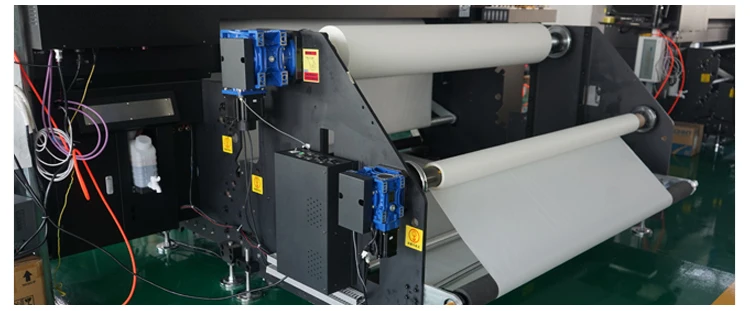

Protection features include large-capacity ink tanks to reduce interruptions, a Germany IGUS double ink chain to safeguard ink tubing, and engineering designed to stabilize ink flow and protect the printheads during long production runs.

10. What mechanical and precision features contribute to print accuracy?

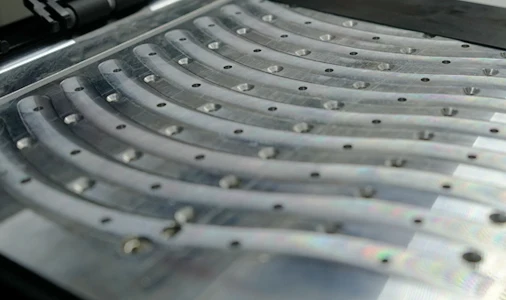

The machine uses imported THK guide rails, linear motors with magnetic grid, magnetic levitation technology and an aluminum 'S' shaped printing platform. These features improve stability and precision, with stated deviation under 0.05 mm.

11. Is the printer fully automatic?

Yes. The unit is described as fully automatic, with automated media feeding/take-up shafts and systems designed for continuous roll-to-roll production to save labor and time.

12. What additional equipment is needed to complete a sublimation printing workflow?

In addition to the printer and sublimation ink/paper, you will need a heat transfer device (flatbed or rotary heat press) suitable for the size of your printed transfers, and optionally finishing equipment (cutters, sewing machines, etc.) depending on the end product.

13. How heavy is the printer and what are the installation considerations?

The printer weighs approximately 320 kg. Due to its size and weight, professional installation is recommended, and you should ensure adequate floor support, workspace, and access for media rolls and maintenance.

14. What maintenance and servicing does the printer require?

Regular maintenance includes routine printhead cleaning and capping checks, periodic inspection of the ink delivery chain, replacing filters/consumables per the manual, and using recommended sublimation inks. For scheduled servicing and spare parts, contact the supplier or authorized service center.

15. What warranty, spare parts availability and technical support options are offered?

Warranty, spare parts and support options vary by seller and region. The specification sheet does not list warranty details, so contact the vendor or local distributor for information about warranty coverage, service contracts and availability of replacement parts and authorized technicians.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading