B21, China Town Mall, Midrand

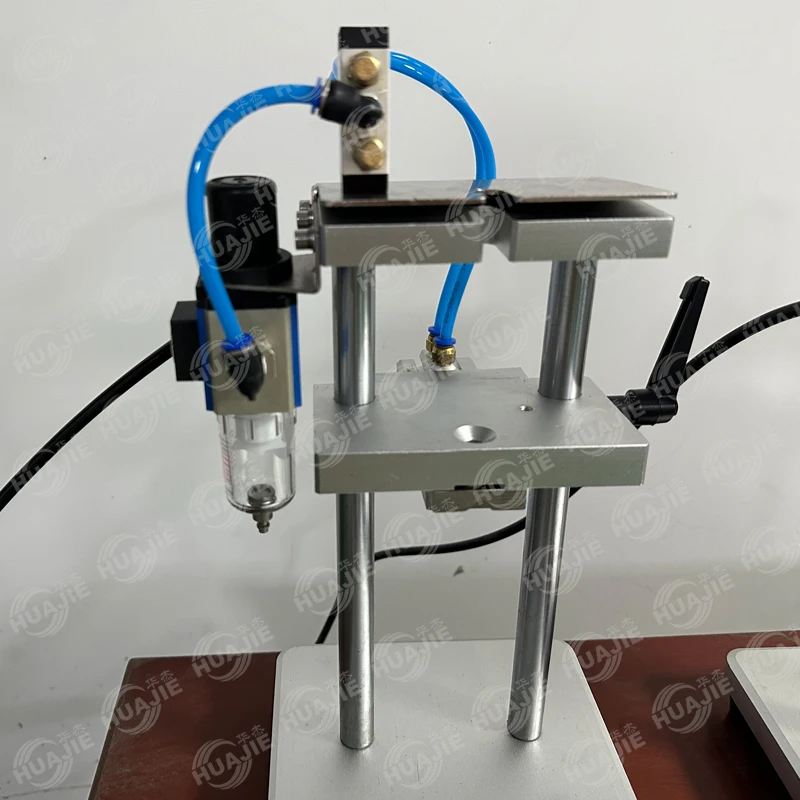

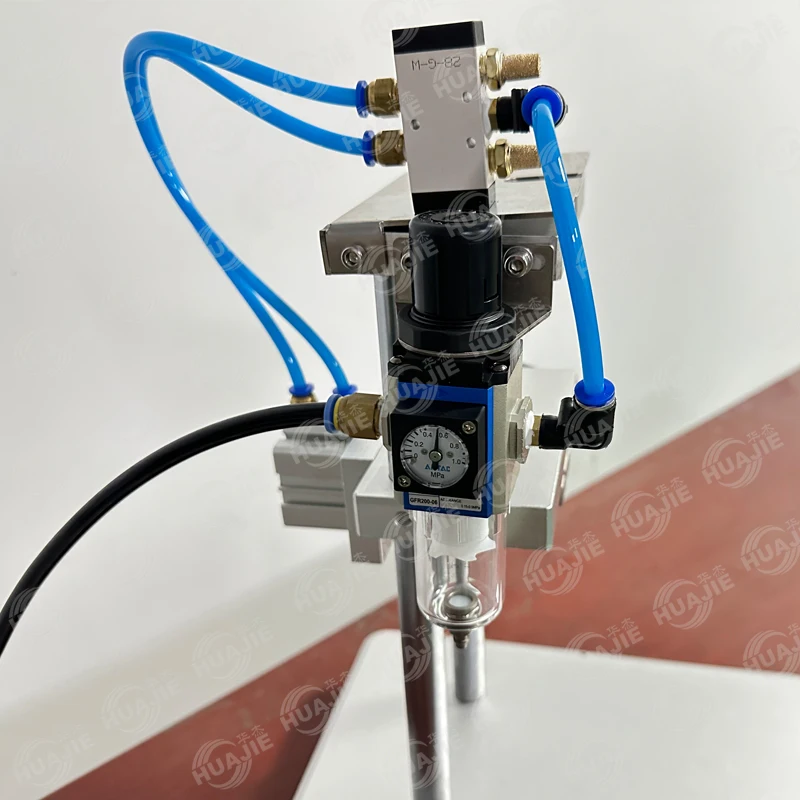

Plastic Pipe Tube Cutting Machine Perfume Sprayer Pump Cutter

- Section : Machinery

- Category : Blister Packaging Machines

- SKU : 1600729127609

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials and tube types can this machine cut?

The machine is designed for plastic tubes including PET and PVC, as well as perfume dip tubes and other thin-walled plastic pipes within the specified diameter range.

2. What tube diameters and lengths are supported?

It supports tube diameters from 1 mm to 30 mm and tube lengths from 50 mm to 180 mm. Special/custom sizes can be provided on request.

3. What is the cutting speed and what affects it?

Cutting speed ranges from 20 to 60 pcs/min. Actual speed depends on tube material, wall thickness, operator technique, air pressure setting, and whether the process is continuous or intermittent.

4. What power or utilities does the machine require?

The unit is pneumatic-driven and requires a compressed air supply. Recommended operating air pressure is 0.4–0.6 MPa (4–6 bar). Use clean, dry, regulated air with a filter/regulator/lubricator for best results.

5. How do I set up and operate the machine?

Setup is minimal: mount the unit on a stable surface, connect to a compressed air line with regulator, set desired air pressure, adjust tube length stop and diameter guides, insert tube, and activate the pneumatic control (foot pedal or trigger) to cut. No complex electrical wiring is required.

6. Is the machine easy for one person to operate?

Yes. The semi-automatic design and compact size (30 x 20 x 40 cm, 8 kg) allow single-person operation for loading, positioning, and cutting tubes.

7. How is cutting quality (burrs/flatness)?

The V-shaped cutting model delivers precise, straight cuts with minimal burr when set to the correct pressure and blade condition. Quality depends on blade sharpness, correct pressure, and proper tube support.

8. How often do I need to replace or service the blade?

Blade life depends on material and production volume. Inspect blades regularly and replace or sharpen when cuts show fraying, increased burr, or require higher air pressure. Typical replacement intervals vary from weeks to months based on usage.

9. What maintenance is required?

Regularly: keep cutting area clean, check and lubricate moving pneumatic components per supplier guidance, replace blades as needed, drain condensate from the air line, and inspect fittings and safety guards. Disconnect air before maintenance.

10. Is the tube length adjustable and repeatable?

Yes. Tube length is adjustable within the 50–180 mm range, and the machine can be set up for repeatable, consistent length stops for batch cutting.

11. Can this machine be integrated into a production or packaging line?

The compact, pneumatic-driven design makes it suitable for small production lines and packaging setups. Integration depends on your line’s automation and handling; consult the supplier for custom integration options.

12. What safety precautions should I follow?

Always wear appropriate PPE (safety glasses, gloves), ensure guards are in place, keep hands clear of the cutting area while operating, and isolate the air supply before servicing. Train operators on safe pneumatic equipment use.

13. Are spare parts and customization available?

Yes. Blades, pneumatic components, and other spare parts are typically available. Customization of tube length and other specs can be arranged—contact the supplier for options, lead times, and pricing.

14. Do you offer testing, warranty, and after-sales support?

Most suppliers offer pre-shipment testing, a warranty period, and after-sales support including parts and technical guidance. Contact the vendor for specific warranty terms, testing samples, and support arrangements.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading