B21, China Town Mall, Midrand

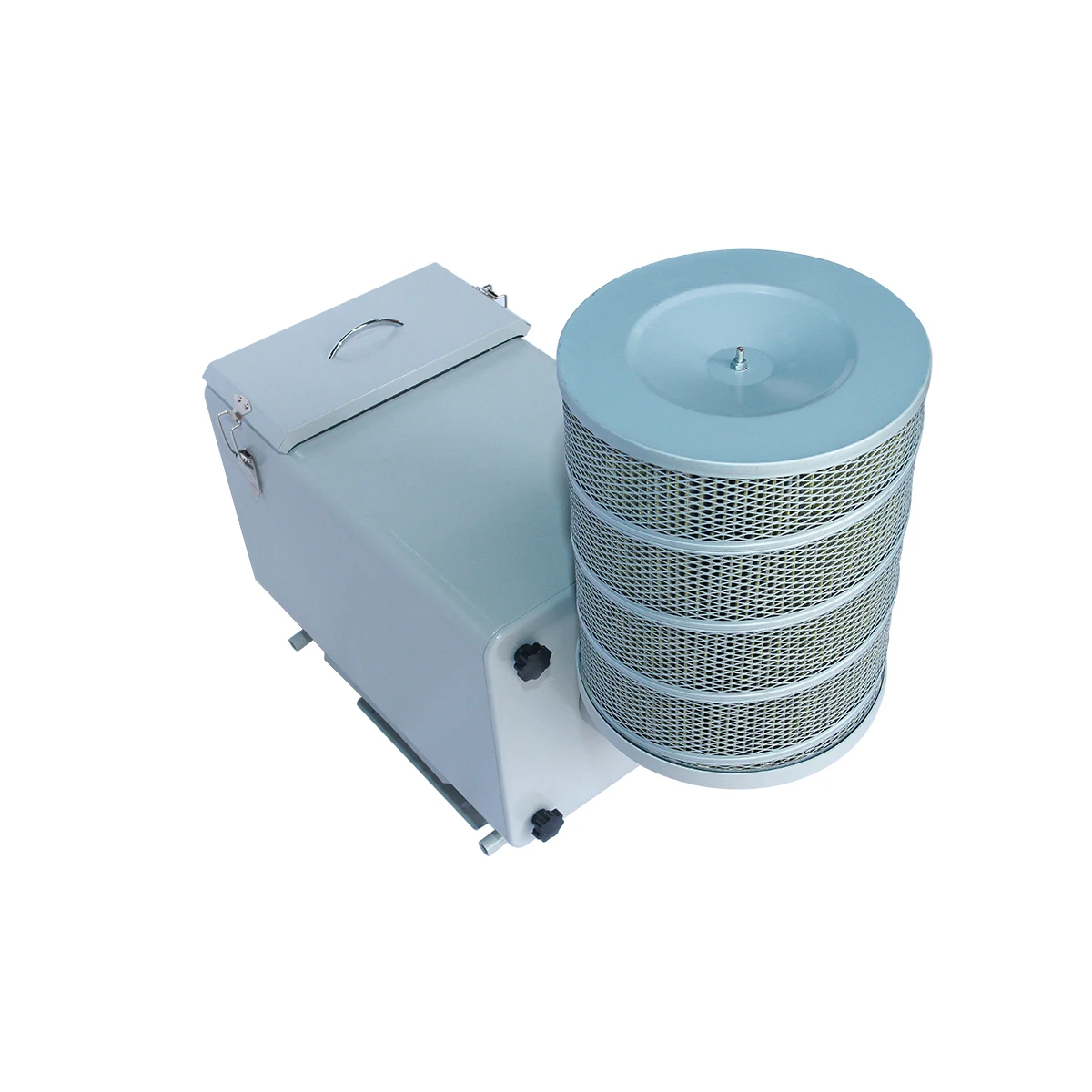

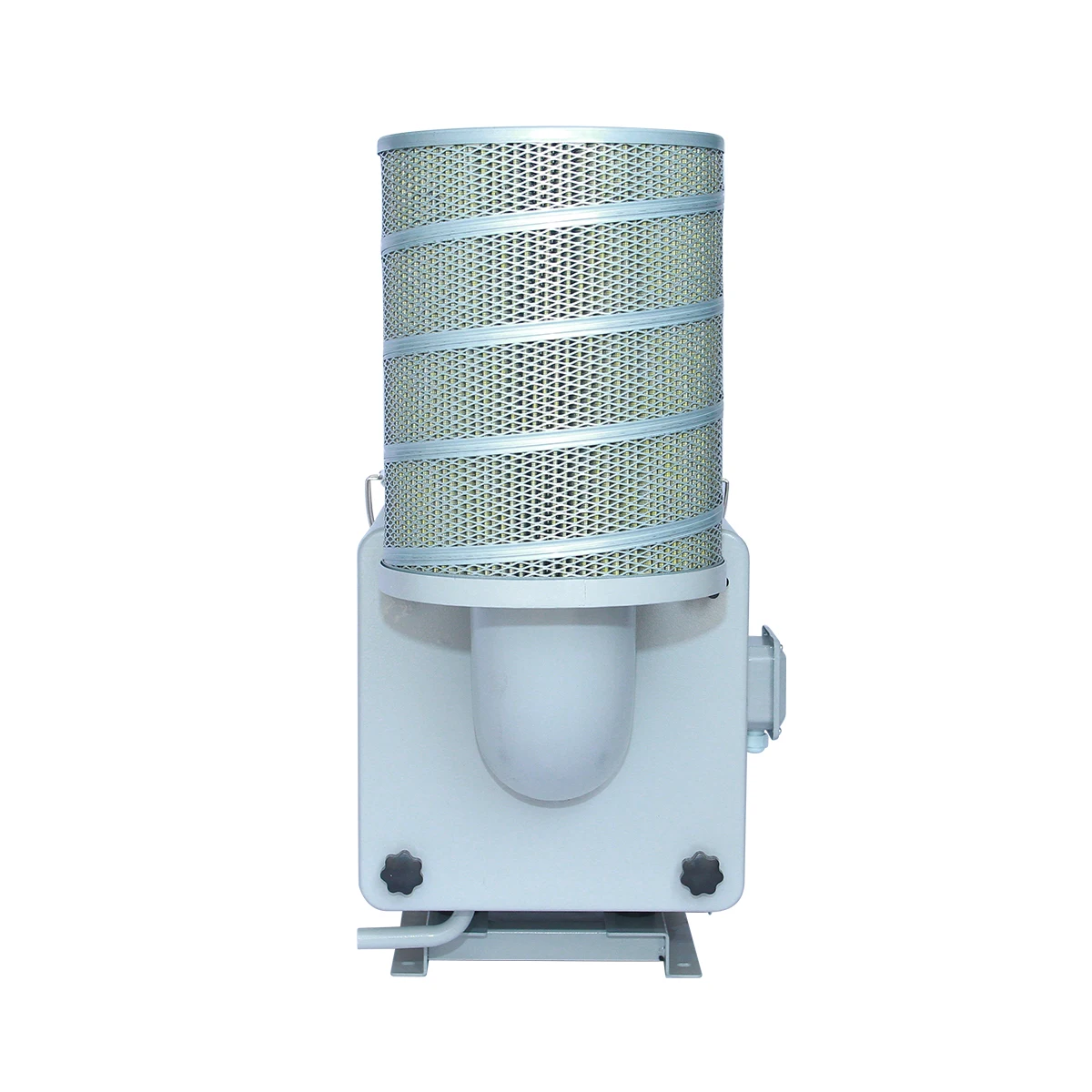

Oil Mist Separator Dust Steam Oil Mist Collector

- Section : Machinery

- Category : Air Cleaning Equipment

- SKU : 1600647136869

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the main function of the Oil Mist Separator Dust Steam Oil Mist Collector?

The main function of the Oil Mist Separator is to collect and filter oil mist, dust, and steam generated during machining processes, ensuring a cleaner working environment.

2. What is the horsepower of the fan used in this oil mist collector?

The fan used in the Oil Mist Separator has a horsepower of 750 W.

3. What is the airflow volume of this oil mist collector?

The airflow volume of the Oil Mist Separator is between 600 to 800 cubic meters per hour.

4. What is the airflow pressure provided by this unit?

The airflow pressure of the Oil Mist Separator is 1200 Pa.

5. How noisy is the Oil Mist Separator during operation?

The operational noise level of the Oil Mist Separator is 62 dB(a), which is relatively moderate for industrial equipment.

6. What is the collection efficiency of the oil mist collector?

The collection efficiency of the Oil Mist Separator is 95%, ensuring effective removal of mist and particles.

7. What is the diameter of the suction entrance?

The diameter of the suction entrance is 125 mm.

8. What are the overall dimensions of the oil mist collector?

The overall dimensions of the Oil Mist Separator are 645 mm in length, 480 mm in width, and 400 mm in height.

9. How much does the Oil Mist Separator weigh?

The weight of the Oil Mist Separator is 32 kgs.

10. Is this oil mist collector suitable for all types of machining operations?

Yes, the Oil Mist Separator is suitable for various machining operations that generate oil mist, dust, and steam.

11. Can this unit be used in a small workshop?

Yes, the compact design and efficiency of the Oil Mist Separator make it ideal for use in small workshops as well as larger industrial settings.

12. What maintenance is required for the Oil Mist Separator?

Regular maintenance includes checking and cleaning the filters, ensuring the fan is operating efficiently, and inspecting for any wear or damage.

13. Does the Oil Mist Separator require any special installation?

The Oil Mist Separator is designed for easy installation and can typically be set up without the need for special equipment or extensive modifications.

14. What type of filter is used in the Oil Mist Separator?

The Oil Mist Separator uses a high-efficiency filter designed to capture oil mist and particulate matter, providing a clean air output.

15. Is the Oil Mist Separator portable?

While the Oil Mist Separator is relatively compact, its weight of 32 kgs may require it to be positioned in a designated area rather than frequently moved.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading