B21, China Town Mall, Midrand

Multi-function small automatic teabag tea bag packaging packing machine Model: GX-220DKF

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1601030759454

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Multi-function small automatic teabag packing machine Model GX-420DKF?

The GX-420DKF is a fully automatic, multi-function tea bag and sachet packing machine designed for triangle tea bags, vertical sachets and similar packaging. It features a full stainless-steel construction, intelligent microcomputer control, double vibration feeding for powders, PID temperature control for sealing, and modular/divided design for smooth, low-noise operation.

2. What bag styles and products can the GX-420DKF pack?

It can make triangle tea bags and vertical sachets and is suitable for packing tea leaves, powdered tea, herbs, dry powder, granules, seeds, grains, beans and small hardware/components.

3. Which packaging materials (films) are compatible with this machine?

Compatible materials include plastic film, laminated film, aluminum foil, filter paper, non-woven fabrics and other heat-sealable compound materials (film must be suitable for heat sealing).

4. What are the packing size limits and filling range for the GX-420DKF?

Maximum roll film width: 420 mm. Bag length range: 10–260 mm. Bag width range: 120–200 mm. Filling range: approximately 100–1000 g (depending on product characteristics and dosing configuration).

5. What are the machine dimensions, weight and power requirements?

Machine footprint (L*W*H): 890 × 490 × 1850 mm. Net weight: about 101 kg. Power supply: 220 V / 110 V, 50/60 Hz. Power consumption is in the domestic small industrial range—confirm the exact wattage with your supplier before purchase.

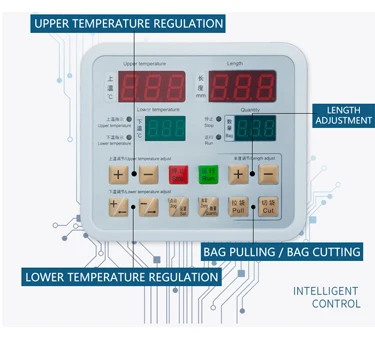

6. How is the machine controlled and how do I set filling weight and bag length?

The machine uses an intelligent microcomputer controller with a button control interface. Bag length and sealing temperature are adjustable on the display; filling weight can be set directly from the control panel for quick adjustments.

7. How accurate is the filling and what ensures consistent dosing?

Accuracy is improved by the machine's metering mechanism and double vibration device (which helps settle and dose powders). Exact accuracy depends on product properties (particle size, flowability); for precise tolerances, perform a product-specific trial or request accuracy data from the supplier.

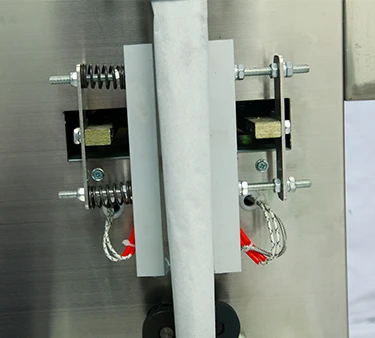

8. What sealing and cutting features does the machine have?

It has #304 stainless steel components including a bag former, independent PID temperature control for neat back sealing, and durable sealing/cutting blades (sharp knife blocks) to create strong, consistent seals and clean cuts.

9. How do I change bag width or bag former?

Different bag widths require changing the stainless-steel bag former. The former is a replaceable part; changeover time depends on operator experience but the modular design is intended to make it straightforward and quick.

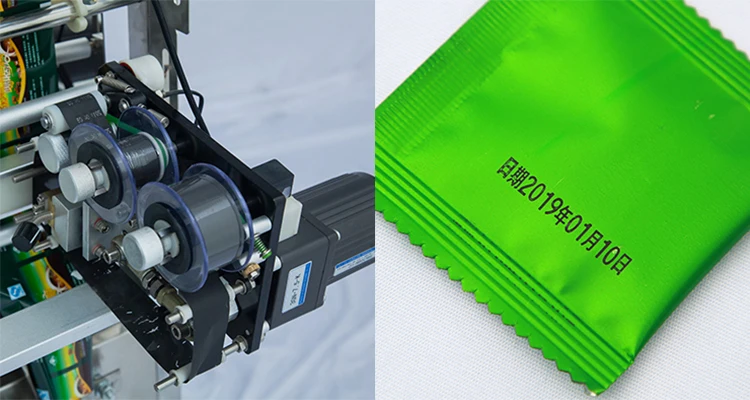

10. Are there optional devices and what do they do?

Yes. Optional devices include a photoelectric eye (high-precision color-mark tracking for accurate cutting), a date printer (prints expiration, batch and manufacture dates; location adjustable), and additional metering devices for specialized dosing.

11. Is the machine easy to move and install?

Yes. The machine is equipped with universal wheels for easier movement. Installation and leveling should be performed on a flat surface and electrical connections made by qualified personnel following local regulations.

12. What hygiene and material standards does the GX-420DKF meet?

The machine is constructed in full stainless steel (#304 where indicated) and designed for food-grade use. Surfaces in contact with product are made to be cleaned; always follow cleaning protocols to maintain hygiene and avoid cross-contamination.

13. What routine maintenance is required?

Routine maintenance includes cleaning the film path and product contact areas after use, inspecting and replacing sealing blades as needed, checking/adjusting tension on film rolls, lubricating moving parts per the manual, and periodically checking electrical and pneumatic connections. Follow the supplier's maintenance schedule.

14. How can I get spare parts, technical support or warranty information?

Spare parts (e.g., sealing blades, bag formers, sensors) and technical support are typically provided by the manufacturer or authorized distributor. Warranty terms vary—confirm warranty period, scope and after-sales service with your supplier before purchase and keep machine serial/model information handy for support.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading