B21, China Town Mall, Midrand

modern Tubular Spreading Machine

- Section : Machinery

- Category : Embroidery Machines

- SKU : 1601089311394

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the modern Tubular Spreading Machine?

The modern Tubular Spreading Machine is an automated fabric spreading system designed for tubular knitted fabrics used in apparel production. It unwinds and spreads tubular material flat and continuously onto a cutting table or conveyor to prepare fabric for cutting and downstream processes. The unit referenced is a Richpeace spreading machine tailored for garment factories.

2. What types of fabrics can it handle?

It is optimized for tubular knitted fabrics such as jerseys, interlocks, single- and double-knits, and similar stretch and non-stretch tubular materials. For specialty fabrics (very heavy, extremely lightweight, or highly textured), confirm compatibility with the supplier.

3. How does the machine work?

The machine opens the tubular fabric and lays it flat in a controlled, tension-managed manner onto the cutting or stacking area. It typically uses adjustable guide rollers, motorized drive systems and programmable controls to maintain alignment, tension and overlap as it spreads.

4. Can it integrate with my cutting table or automated cutting line?

Yes. Modern spreading machines, including Richpeace models, are designed to integrate with manual cutting tables or automated cutting systems. Integration details (height, interface, feeding method) are model- and site-specific, so coordinate with your cutting table supplier and the Richpeace representative for exact integration options.

5. What spreading speed and production capacity should I expect?

Spreading speed and throughput vary by model, fabric type and operator settings. Modern machines offer adjustable speeds to balance accuracy and productivity for high-volume garment factories. Request model-specific performance charts from the vendor to estimate capacity for your fabric mix.

6. How many layers can the machine spread and does it do multi-layer stacking?

Tubular spreading machines typically lay fabric in single continuous plies; multi-layer stacking depends on the downstream handling and cutting system. Some workflows use continuous spread to create stacks on a conveyor or cutting bed. For high-layer stacking needs, discuss model capabilities and recommended workflows with the supplier.

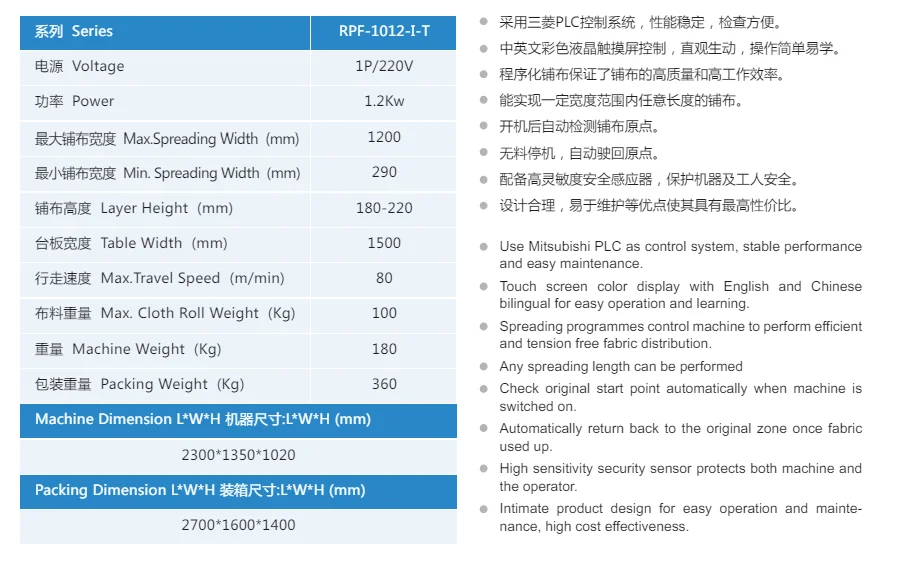

7. What control system and user interface does it use?

Modern units commonly use programmable PLC controls with an operator touchscreen for setting spread length, speed, tension, and other parameters. Specifics (brand of PLC, touchscreen size, recipe storage) depend on the model; ask for the control spec sheet if you need particular functionality.

8. How is fabric tension and edge alignment managed?

The machine manages tension via adjustable drive rollers and tension sensors to prevent distortion. Edge alignment is controlled by fabric guides and alignment systems; some models offer automatic edge-detection and centering for consistent layup. Exact features vary by configuration.

9. What are the typical power and space requirements?

Power consumption and footprint depend on the model and options. Most modern spreading machines require standard industrial three-phase power and need floor space for the spreader plus access to a cutting table or conveyor. Provide your site power and floor layout to the vendor so they can confirm electrical and space requirements for the chosen model.

10. What safety features does the machine include?

Safety features commonly include emergency stop buttons, safety guards around moving parts, safety interlocks, warning indicators and compliant electrical protections. Specific certifications and safety options (e.g., light curtains) should be verified with the manufacturer for your region's requirements.

11. What maintenance is required and how often?

Routine maintenance includes keeping guides and rollers clean, checking and adjusting tension components, lubricating moving parts per schedule, inspecting belts and motors, and verifying sensor/PLC operation. Frequency depends on usage — daily visual checks and scheduled preventive maintenance (monthly/quarterly) are typical. The vendor provides a maintenance manual and recommended intervals.

12. Are spare parts and technical support available?

Yes. Richpeace and authorized dealers generally provide spare parts, consumables and technical support. Ask about local spare-parts availability, lead times, recommended spare parts kit and options for remote or on-site service contracts.

13. What optional features or upgrades are available?

Common options include automatic edge-detection and centering, anti-static devices, extended length feeding, fabric roll holders, remote monitoring, integration interfaces for cutting systems, and specialty guides for delicate fabrics. Confirm available options for the specific model you plan to purchase.

14. Do you provide installation, commissioning and operator training?

Most suppliers offer installation, commissioning and operator training services, either included or as a paid option. Training typically covers safe operation, setting up spread parameters, basic troubleshooting and routine maintenance. Confirm scope, duration and cost with the vendor.

15. What warranty and after-sales service come with the machine?

Warranty terms vary by supplier and model; typically there is a limited manufacturer warranty covering defects in materials and workmanship for a specified period. After-sales services may include spare parts supply, on-site repairs, remote diagnostics and service contracts. Request the warranty document and service options before purchasing.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading