B21, China Town Mall, Midrand

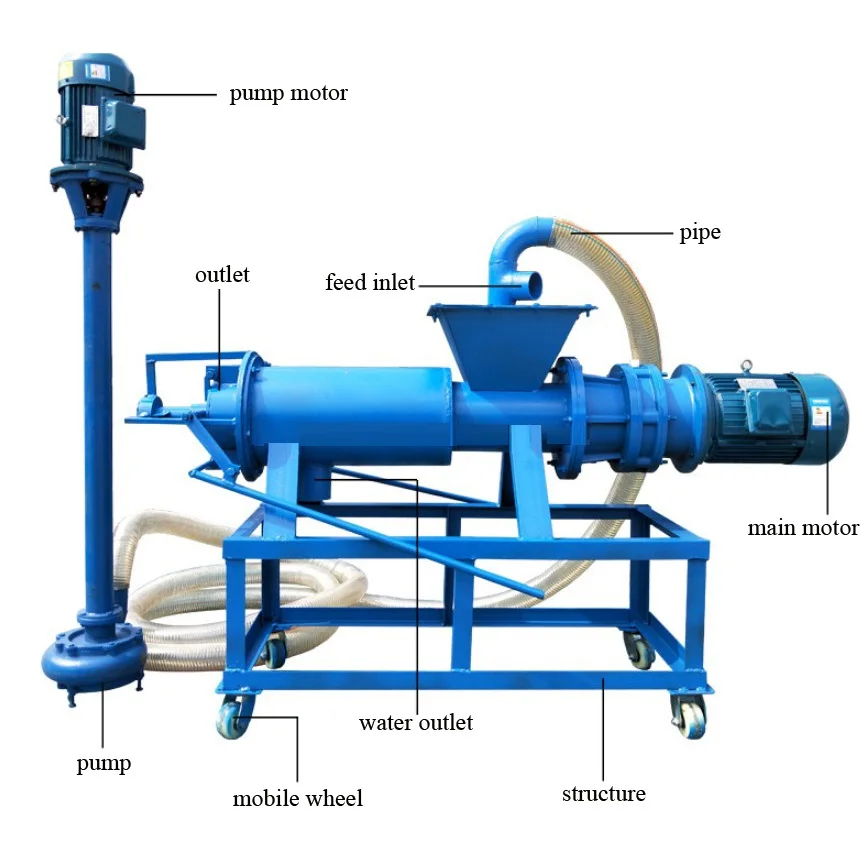

Manufacture chicken farm durable chicken manure dewatering machine

- Section : Machinery

- Category : Other Agricultural Equipment

- SKU : 1600416229209

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Manufacture chicken farm durable chicken manure dewatering machine?

It is a manure dehydrator (solid–liquid separator) that separates pig, cow, duck and chicken manure into liquid organic fertilizer and solid organic fertilizer by forcing raw manure through a screw-and-screen separator.

2. Which types of manure can this machine process?

Designed for a wide range of livestock and poultry manures including chicken, pig, cow, duck and other farm slurries. It handles mixed manure and manure with typical farm solids.

3. How does the separation process work?

A mud pump feeds raw manure water into the unit. A screw shaft within a cylindrical screen squeezes and conveys solids while liquid flows through the screen to the liquid outlet, producing separated liquid fertilizer and dewatered solids.

4. What models and technical specifications are available?

Available models: FC-130, FC-150, FC-280. Typical specs: FC-130 — Voltage 220V/380V, Main power 4 kW, Pump 3 kW, Weight 230 kg, Dimensions 1700×600×1150 mm, Wet manure suction 20 CBM, Dry manure capacity 5 CBM. FC-150 — Voltage 380V, Main power 5.5 kW, Pump 3 kW, Weight 360 kg, Dimensions 1780×700×1200 mm, Wet manure suction 22 CBM, Dry manure capacity 7 CBM. FC-280 — Voltage 380V, Main power 7.5 kW, Pump 3 kW, Weight 420 kg, Dimensions 2000×800×1500 mm, Wet manure suction 25 CBM, Dry manure capacity 15 CBM.

5. What are the power and electrical requirements?

Power requirements depend on model: main motor 4–7.5 kW and pump motor 3 kW. FC-130 can be supplied as 220V or 380V; FC-150 and FC-280 are 380V. A suitably rated, grounded power supply and correctly sized cables are required.

6. What is the processing capacity of the machine?

Model wet manure suction capacities are approximately 20 CBM (FC-130), 22 CBM (FC-150) and 25 CBM (FC-280). Dry (dewatered) output volumes depend on input solids content and model (typical listed as ~5, 7 and 15 CBM respectively).

7. What are the uses of the separated liquid and solid fractions?

The liquid fraction can be used directly as liquid organic fertilizer or applied to crops (or further processed). The solids are suitable for transport to low-fertilizer areas, soil amendment, or composting into organic compound fertilizer.

8. What moisture content should I expect in the separated solids?

Moisture reduction is substantial and results in dewatered solids suitable for transport or composting. Exact moisture content depends on input slurry consistency and operating settings; contact the manufacturer for typical percentages under your conditions.

9. Can the machine handle bedding materials (straw, sawdust) mixed with manure?

It can handle typical amounts of bedding included in farm manure. However, very large or long fibrous materials may reduce performance and could require pre-shredding or specialized configuration—consult the supplier for heavy-bedding applications.

10. What are the installation requirements?

Install on firm, level ground with adequate space for inlet, outlet and maintenance access. Provide the correct voltage/power supply, connect the mud pump to the inlet, and arrange liquid and solid discharge points. Professional installation/commissioning is recommended.

11. How should I maintain and clean the dewatering machine?

Regularly clear screens and discharge ports, inspect and lubricate bearings and screw components per the maintenance schedule, check and service the mud pump, and replace worn screening elements. Frequency depends on use; daily visual checks and weekly cleaning are typical.

12. What materials and construction quality does the machine have?

The unit is built for farm use with durable, corrosion-resistant materials in critical parts. For exact material specifications (stainless steel grades, coatings, etc.) request detailed datasheets from the manufacturer.

13. What safety features should I expect and what safety steps are required?

Typical safety features include guards around moving parts, emergency stop, and proper electrical grounding. Operators should follow lockout/tagout procedures, avoid wearing loose clothing near moving parts, and follow the supplied safety manual.

14. Are spare parts, after-sales service and warranty available?

Spare parts such as screens, screws and pump components are normally available. After-sales service and warranty terms vary by supplier—contact the manufacturer or your sales representative to confirm parts availability, service plans and warranty coverage.

15. Can the machine be customized or packaged for shipping/installation on my farm?

Yes — many manufacturers offer customization (different voltages, sizes, hopper/inlet options) and can arrange packaging, shipping and on-site installation support. Contact the supplier with your site details and requirements for a tailored solution.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading