B21, China Town Mall, Midrand

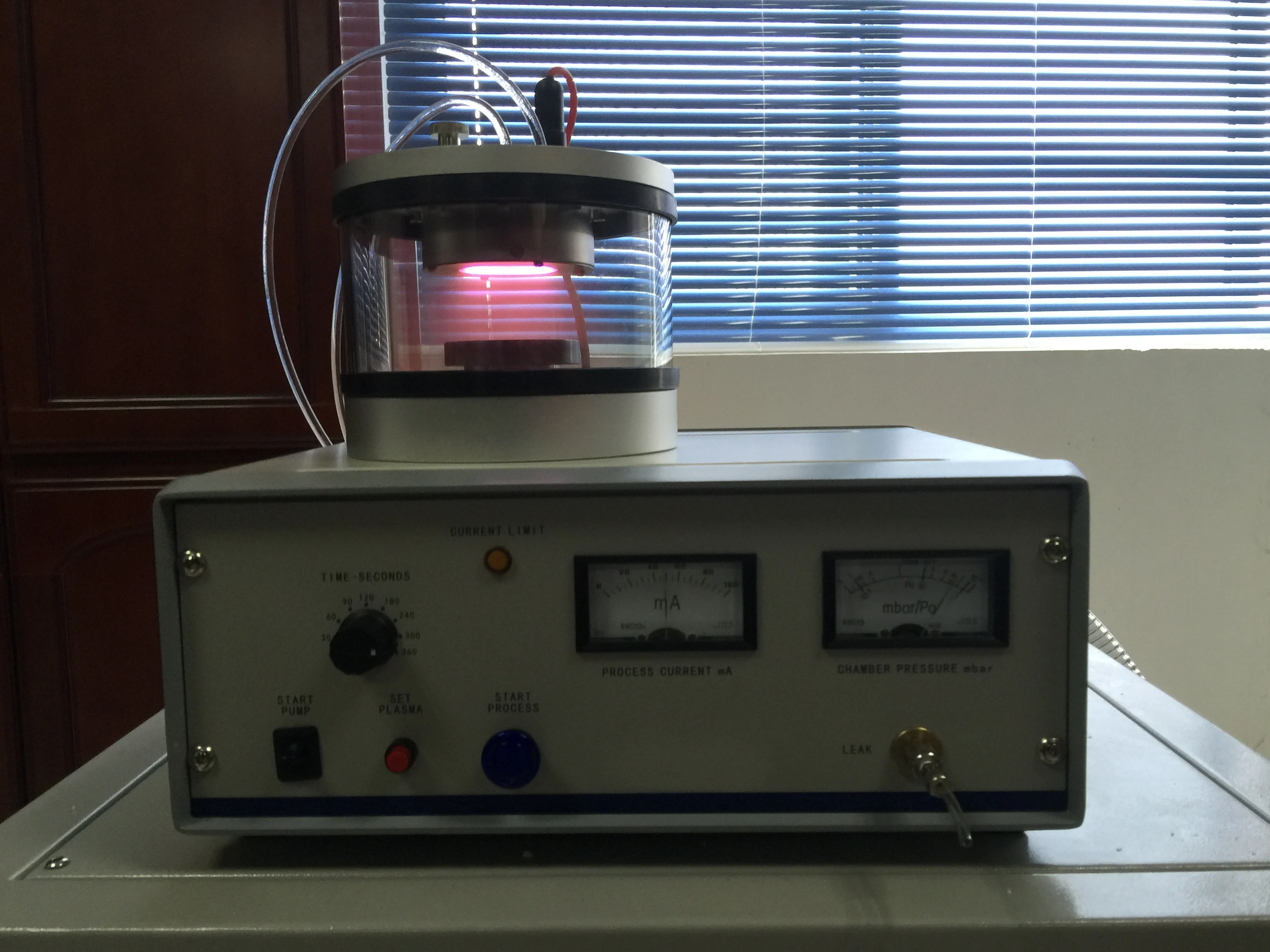

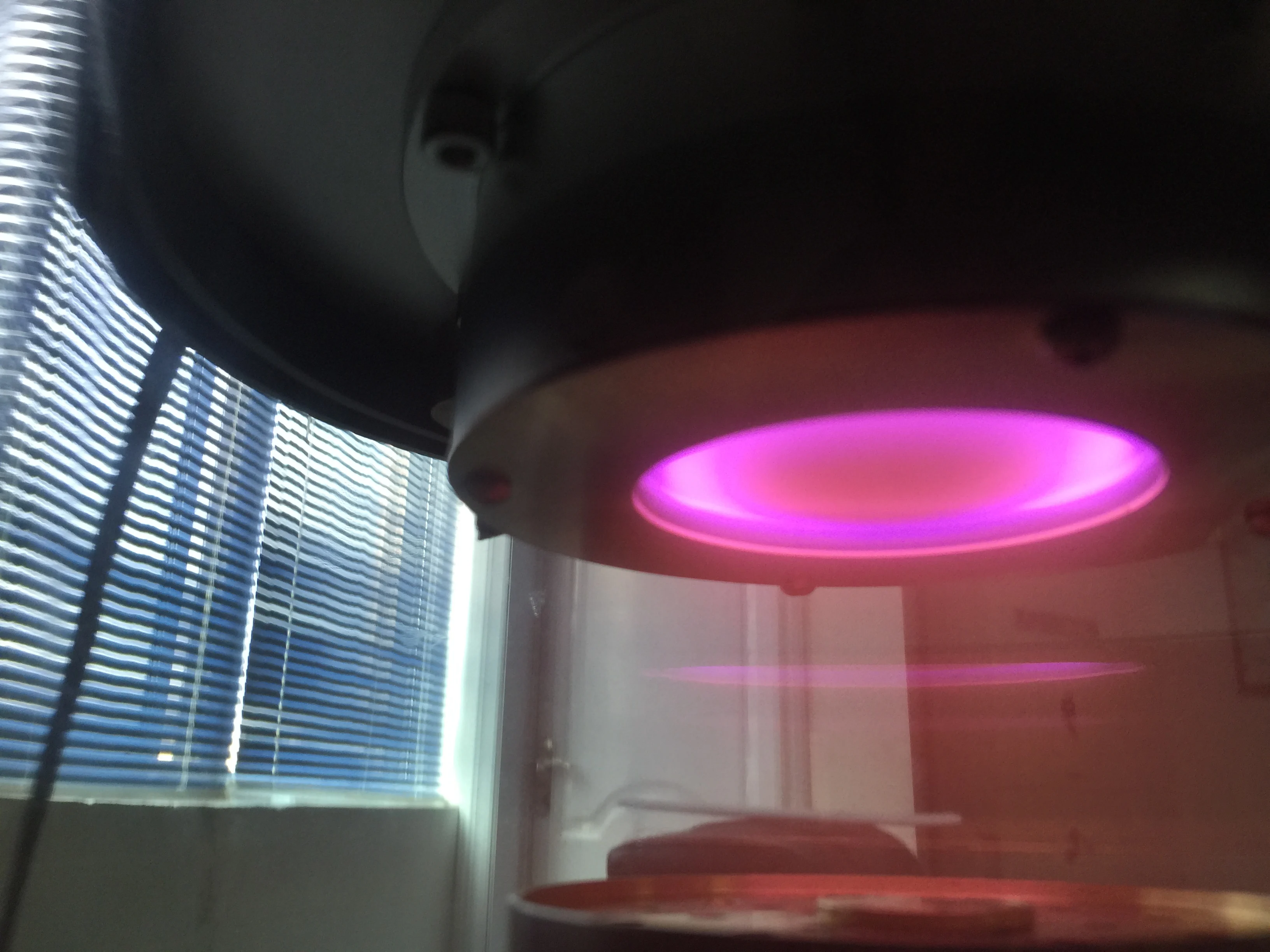

Magnetron Plasma Gold Sputtering Coater

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 1600106757412

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Magnetron Plasma Gold Sputtering Coater and what is it used for?

It is a compact laboratory coating unit that integrates magnetron plasma sputtering and evaporation in one small machine. It is designed primarily to prepare SEM and EDAX samples for microstructure and micro-area composition analysis by applying conductive or thin film coatings (e.g., gold or carbon).

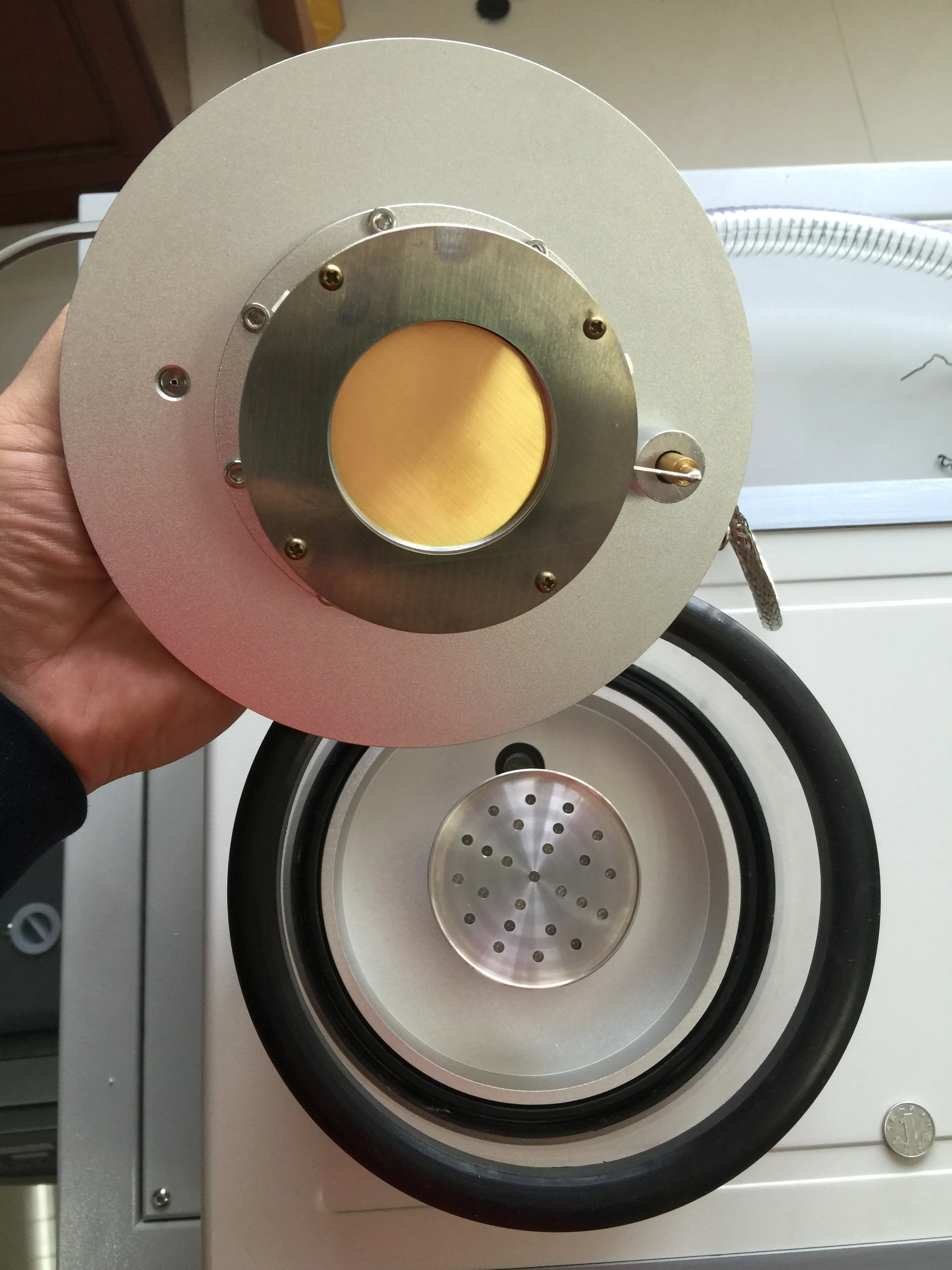

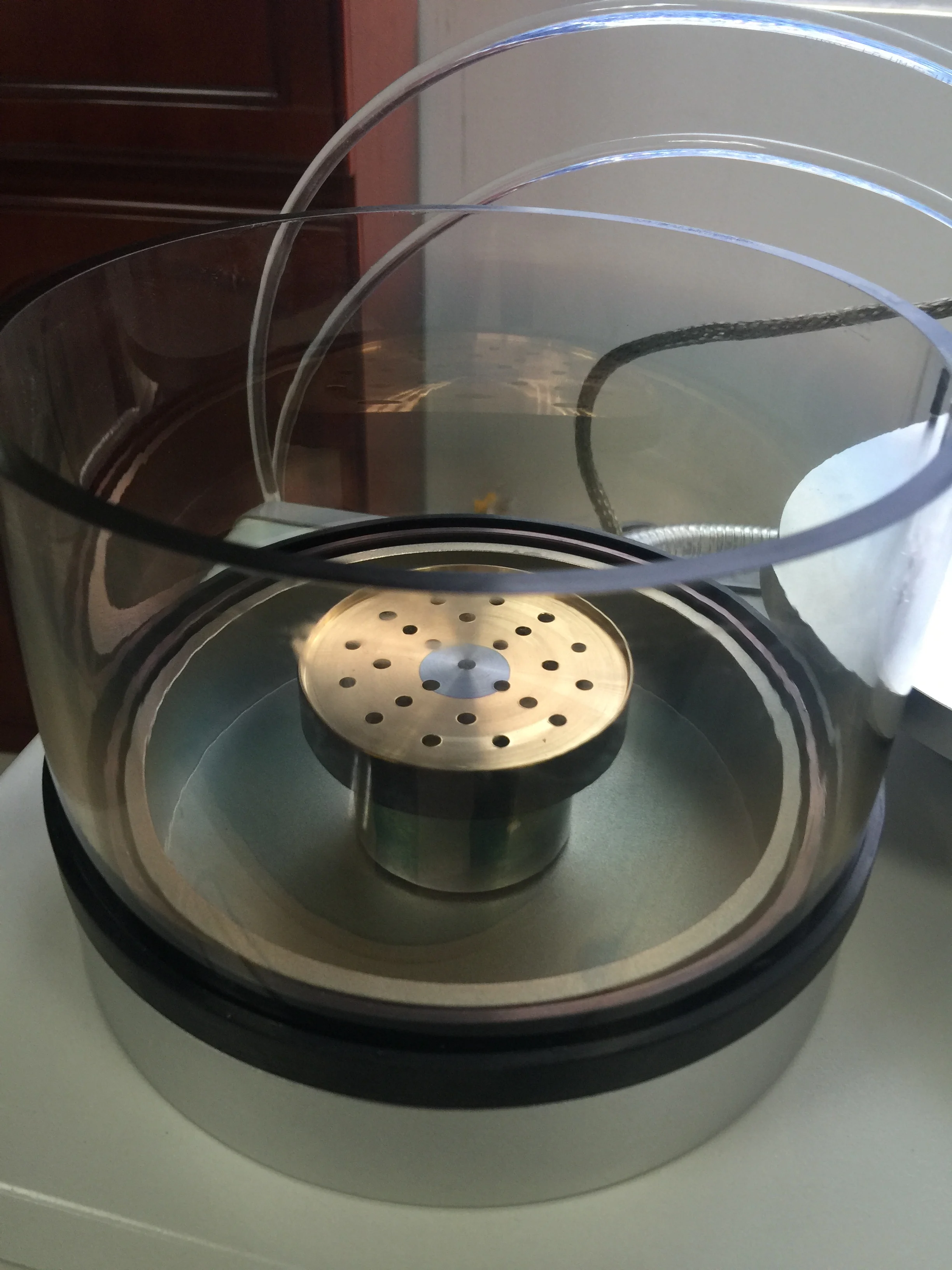

2. What are the main specifications of the unit?

Host dimensions: L360 × W300 × H380 mm. Vacuum chamber: diameter 160 mm, height 120 mm. Standard target: gold, Ø50 mm, thickness 0.1 mm. Sputtering area: Ø50 mm. Vacuum indicator: ≤ 4 × 10⁻² mbar. Mechanical (rotary vane) pump capacity: 2 L/s. Chiller included.

3. Which target materials are supported?

The unit ships with a gold target (Ø50 mm, 0.1 mm thick) and is designed to coat gold and other materials, including carbon. If you need other target materials, contact the supplier to confirm availability and compatibility.

4. What vacuum level does the coater achieve?

The vacuum indicator specification is ≤ 4 × 10⁻² mbar. Actual base pressure reached in practice depends on sample outgassing, pump condition, gas loads and operational settings.

5. What pumping system does the instrument use?

The unit includes a double-step rotary vane vacuum pump (mechanical pump) with a rated pumping speed of 2 L/s. It also supports the use of process gases as required for sputtering.

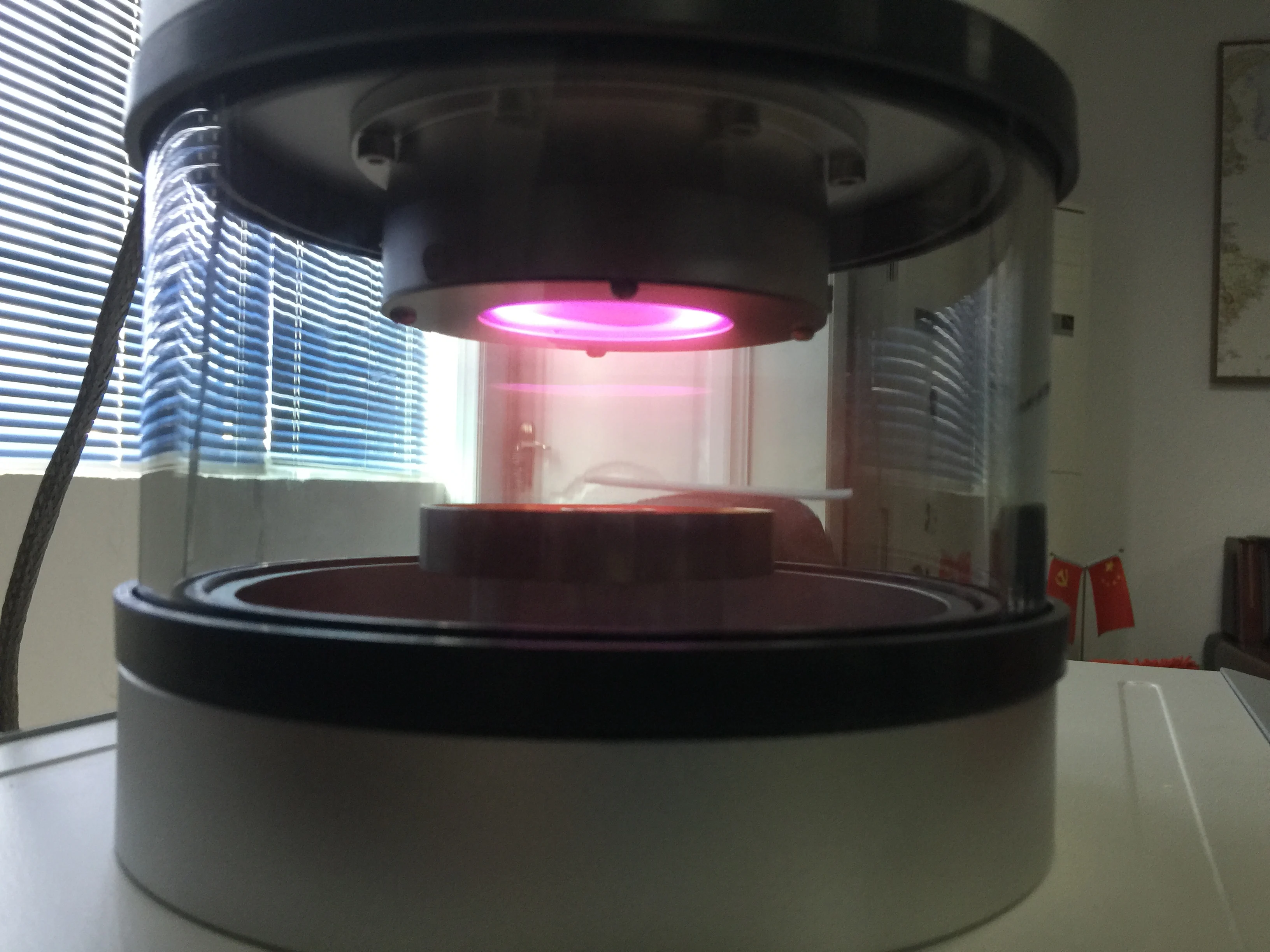

6. How long does a typical coating take?

In our laboratory tests a typical gold coating sufficient for SEM imaging was achieved in about 30 seconds. Coating time depends on desired film thickness, target material, power settings and sample geometry, so times should be calibrated for your application.

7. Can I use this coater for EDAX/EDS analysis?

Yes — the system is intended for SEM and EDAX sample preparation. Note: metallic coatings such as gold can introduce X-ray peaks that may obscure or interfere with elemental analysis for some elements. For EDAX where spectral interference is a concern, carbon coating is commonly used instead of gold.

8. How is coating thickness controlled and measured?

Thickness is normally controlled by adjusting deposition time and process power (current/voltage). The unit does not list an integrated thickness monitor in the provided spec, so users typically calibrate deposition rate using test runs and measure thickness with profilometry, ellipsometry or cross-sectional SEM.

9. How many samples can fit in the chamber?

The available internal space is a cylinder Ø160 mm × 120 mm high. The number of samples depends on their size and the sample holder used. Contact the supplier for specific sample-holder accessories and recommendations for batch loading.

10. What maintenance does the coater require?

Regular maintenance includes keeping the chamber clean, removing sputter debris, checking and changing vacuum pump oil per the pump manufacturer's schedule, inspecting and replacing targets when depleted, and servicing the chiller as recommended. Follow the user manual for detailed maintenance intervals.

11. What consumables and spare parts should I expect to need?

Common consumables include target materials (e.g., gold, carbon targets), vacuum pump oil and seals, and possibly sample holders. Target lifetime depends on usage and process parameters, so keep spare targets on hand. Contact the vendor for official spare parts and recommended consumables.

12. Is installation, training or after-sales support available?

The manufacturer reports long-term international customers and after-sale service support. Specific installation, training and warranty terms are provided by the supplier — contact them directly to arrange on-site installation or user training and to confirm warranty details.

13. Are there any safety considerations I should be aware of?

Yes. The system involves vacuum, high voltage/ RF power for sputtering, and possibly process gases. Use appropriate electrical grounding, follow gas-handling procedures, avoid exposure to deposited particulates, and follow the safety instructions in the operator manual. Only trained personnel should operate or service the unit.

14. Can I switch between sputtering and evaporation modes?

The unit integrates both magnetron plasma sputtering and evaporation capabilities. Mode switching and the required settings are covered in the user manual; contact the supplier if you need a demonstration or application-specific guidance.

15. What additional information is available if I want to buy or specify this coater?

For complete electrical requirements, detailed performance data (deposition rates for various materials), available accessories (sample holders, targets), pricing, lead times and installation specifications, contact the supplier or request the full datasheet and quote.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading