B21, China Town Mall, Midrand

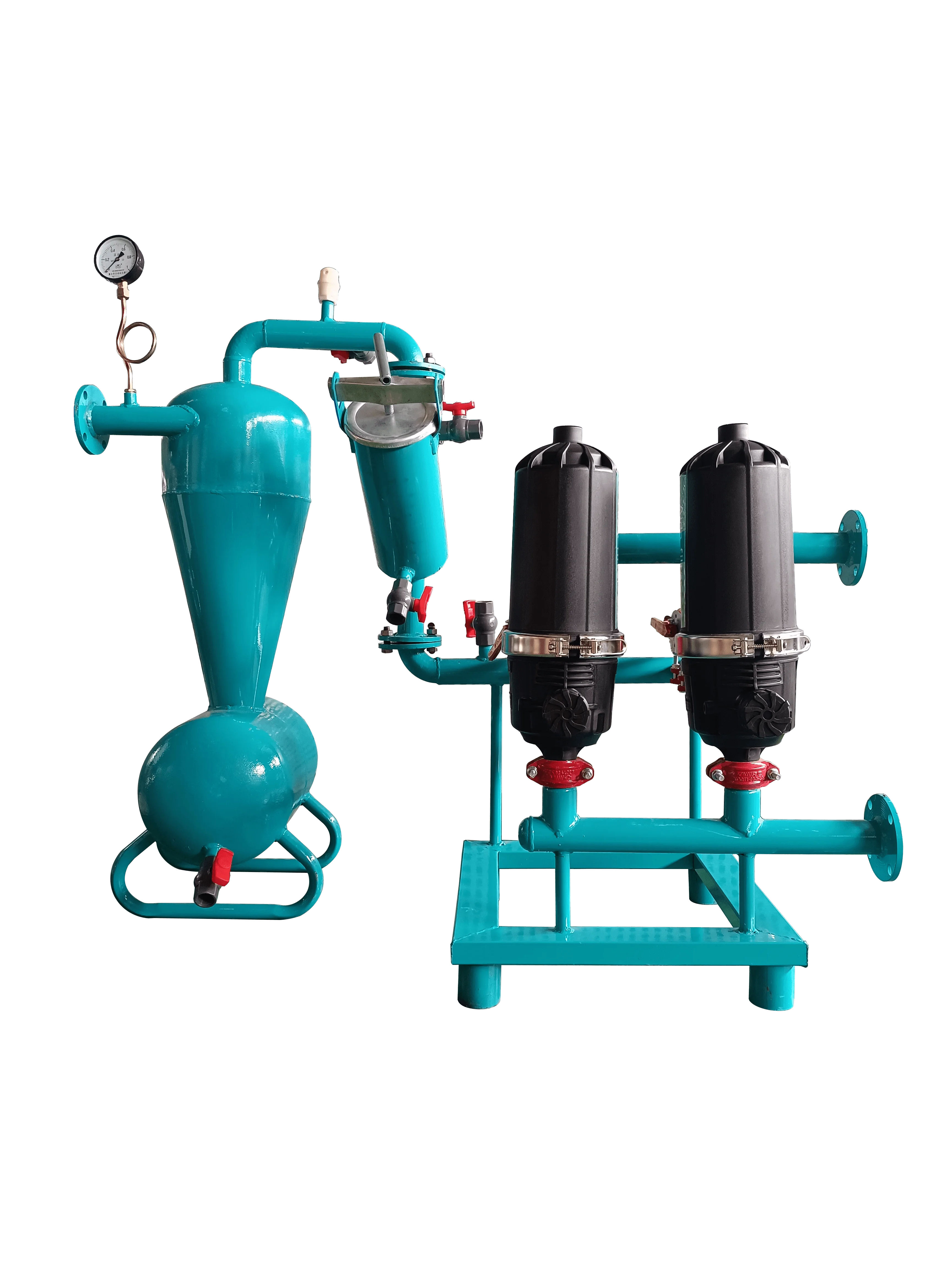

LVDA Drip Irrigation System Auto Back Flushing Disc Filter

- Section : Machinery

- Category : Irrigation Systems

- SKU : 1600602331672

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the LVDA Drip Irrigation System Auto Back Flushing Disc Filter?

It is an automatic disc-type filtration unit for drip irrigation that removes organic and inorganic particles using stacked grooved discs. It features automatic backflushing, durable construction (carbon/stainless steel), selectable filtration from 20–400 microns, and is designed to keep irrigation systems free of debris for continuous operation.

2. How does the automatic backflushing mechanism work?

The controller monitors time and/or differential pressure and periodically triggers a backwash cycle. During backflush the disc stack is rotated and flushed to remove trapped debris, allowing continuous operation with minimal manual intervention. Backwash parameters (drain time, interval, differential pressure) are programmable.

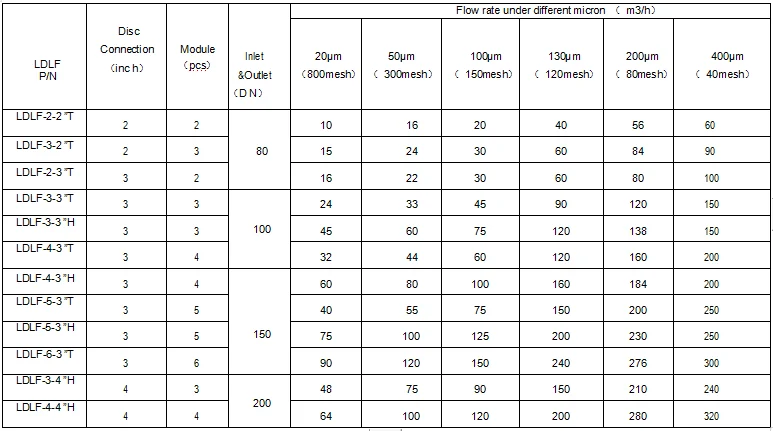

3. What micron sizes are available and how do I choose the right one?

Filter grades range from 20 to 400 microns. Choose finer (lower micron) for sensitive drip emitters or when water contains fine sediments; choose coarser (higher micron) for coarse debris or where higher flow and less frequent cleaning are acceptable. If unsure, provide a water sample or particle analysis to your supplier for recommendation.

4. What operating pressure and flow rates does the filter support?

The filter is designed to operate under system pressures of 0.2–1.0 MPa (200–1000 kPa). Individual units are rated to handle up to approximately 1000 L/hour; for larger flow requirements you can install multiple filters in parallel or consult the supplier for appropriately sized models.

5. What are the electrical/power requirements for the automatic controller?

The controller and automatic components are available in 220V, 380V, or a customized voltage option. Confirm the selected voltage when ordering to match your site power supply.

6. What settings can I adjust on the controller for backflush?

You can set automatic drain (backwash) time from 10 to 600 seconds, the backwash interval from 4 minutes up to 20 days, and differential pressure trigger between 10 kPa and 350 kPa. The controller will initiate backwash when either the time or pressure condition (whichever occurs first) is met.

7. Is a minimum pressure required for backwashing?

Yes. Effective backwash requires a backwashing pressure greater than 180 kPa. If your supply cannot provide this, a booster/backwash pump must be added. Alternatively, water supply may need to be interrupted during backwashing if booster pumping is not used.

8. What materials is the filter made from and is it corrosion resistant?

The main construction materials include carbon steel and stainless steel, chosen for durability in agricultural and industrial environments. For specific corrosive conditions (e.g., saline water or aggressive chemicals), discuss material options and coatings with the supplier to ensure compatibility.

9. How often should I perform maintenance and what is required?

The system is low maintenance due to automatic backflushing. Routine checks are recommended: inspect discs and seals periodically (monthly or per site conditions), verify controller settings, check for leaks, and replace worn seals or discs as needed. Manual cleaning of the disc head is possible if heavy fouling occurs.

10. Can I manually clean the disc filter if needed?

Yes. The disc head can be manually removed and cleaned if required, which is useful after heavy contamination or before storing/inspecting the unit.

11. What spare parts are available and which wear parts should I keep on hand?

Common spare parts include disc elements, seals/gaskets, control valve components, and controller modules. Keep a set of replacement discs and seals on hand for faster servicing. Contact your supplier for an exact spare-parts list matched to your model.

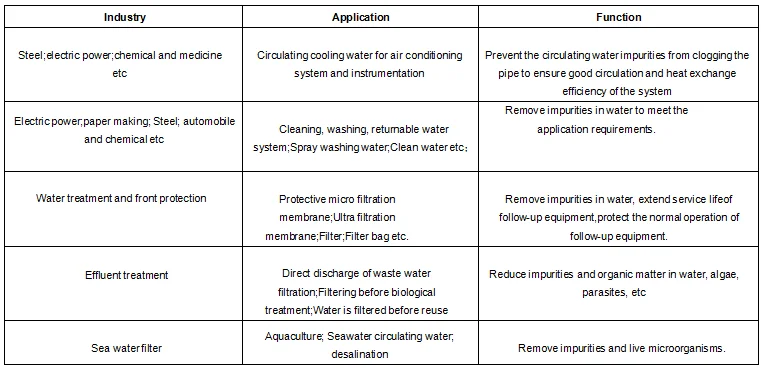

12. What industries and applications is this filter best suited for?

It's suitable for agricultural drip irrigation, greenhouse irrigation, nurseries, and industrial water filtration applications in manufacturing, energy, and mining where reliable removal of organic/inorganic particles is required and continuous operation is desired.

13. How water- and energy-efficient is the auto backflushing design?

The disc design and HELIX optimization minimize backwash frequency and water consumption compared with many traditional filters. Automatic targeted backwashing reduces wasted water and operator intervention, contributing to energy and labor savings.

14. What warranty and support are provided?

The product includes a 1-year warranty on core components. For warranty coverage details, installation support, commissioning, and spare parts availability, contact the supplier or authorized dealer.

15. What should I do if the filter experiences low flow, frequent backwashing, or pressure loss?

Common checks: verify inlet supply pressure (ensure backwash pressure >180 kPa), confirm controller settings for differential pressure and interval, inspect and clean the disc stack manually if heavily fouled, check for clogged upstream strainers, and examine seals and valves for leaks. If issues persist, contact technical support with system details and water quality information.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading