B21, China Town Mall, Midrand

LTPK Honey Stick Packing Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600898687413

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 24 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

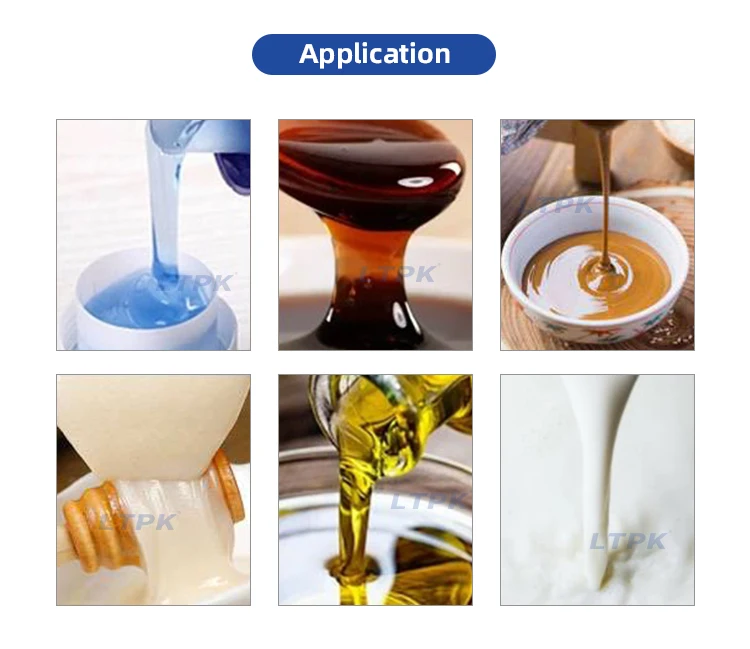

1. What products can the LTPK Honey Stick Packing Machine handle?

The machine is designed for honey and other liquid/paste products such as ketchup, sauces, mayonnaise, jams, beverages, edible oils, cosmetics and some chemical liquids. It works with a wide range of viscosities (liquids to medium-thick pastes).

2. What is the machine's packing speed?

Typical packing speed is 15–25 bags per minute. Actual speed depends on product viscosity, filling volume, bag length and operator settings.

3. What filling volumes and accuracy does it offer?

Standard filling range is 25–125 ml (customizable). Filling accuracy is ±1%, ensuring consistent dose control when the machine is properly calibrated.

4. What bag sizes and film widths are supported?

Bag length is adjustable from 0 to 16 cm. Maximum film width is 22 cm (customizable). Custom film widths and bag lengths can be accommodated with configuration changes.

5. What sealing type and packaging materials are compatible?

The machine uses a back-side seal and requires heat-sealable films or composite materials (plastic, paper-laminates, etc.). Materials must be compatible with the machine's heat-sealing temperature range.

6. What are the machine's electrical and power requirements?

Voltage options are 220V or 110V, 50/60 Hz. The rated power is 500 W. Confirm local electrical supply and grounding before installation.

7. What are the machine dimensions and weight?

Machine size is approximately 50.5 × 50 × 159 cm and it weighs about 110 kg.

8. Is the machine easy to operate and maintain?

Yes. It is fully automatic with user-friendly controls. Routine maintenance includes daily cleaning of product-contact parts, periodic lubrication of moving parts, and routine inspection of seals and electrical connections.

9. Is the machine hygienic and suitable for food use?

Yes. It is built from 304 stainless steel for product-contact parts, offering good corrosion resistance and easy cleaning. For food-grade use follow recommended cleaning and sanitization procedures.

10. Can the machine handle products that require heating or mixing (e.g., high-viscosity sauces)?

Yes. An optional mixing and heating function can be added to the hopper to improve flow and reduce residue for products like chili paste or thick sauces.

11. What customization options are available?

Customizable options include filling range, bag length, maximum film width, hopper configuration (mixing/heating), and sometimes special dosing pumps or nozzles tailored to product viscosity.

12. What common problems might occur and how are they solved?

Common issues include inconsistent fills (check calibration, pump/nozzle speed and product viscosity), weak seals (adjust sealing temperature/pressure and check film compatibility), and film feeding jams (inspect film tension and path). Refer to the manual or contact technical support for troubleshooting.

13. Are spare parts, installation, and training provided?

Most suppliers provide spare parts, installation and commissioning services, and operator training or manuals. Availability and terms vary by vendor—confirm with your supplier.

14. How energy efficient is the machine?

The machine operates at a relatively low power rating (500 W) and is suitable for 110/220V supplies. Actual energy use depends on operating hours and optional accessories like heaters or mixers.

15. What are the lead time, warranty and after-sales support options?

Lead time, warranty length and after-sales support differ by manufacturer and distributor. Contact the supplier for specific delivery times, warranty coverage and service/maintenance contracts.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading