B21, China Town Mall, Midrand

KLT Servo Powder Compacting Press - Model YKT-50t

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 1600095184780

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

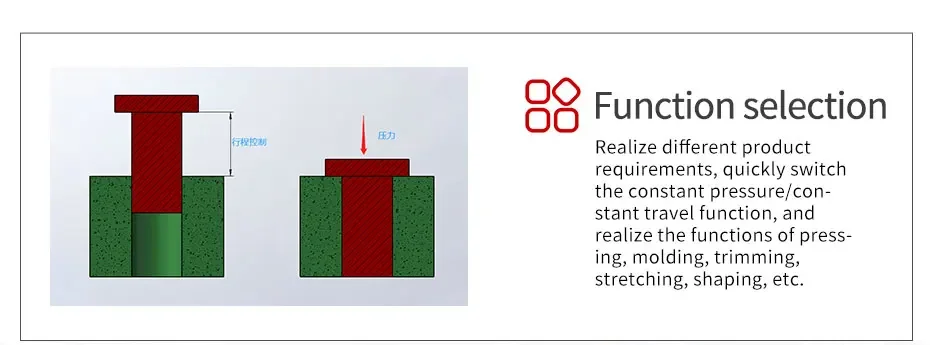

1. What is the KLT Servo Powder Compacting Press - Model YKT-50t?

The YKT-50t is a compact, high-efficiency servo-driven powder compacting press designed for household and industrial powder-metallurgy applications, offering precise control, robust construction and suitability for large-scale production.

2. What are the key technical specifications of the YKT-50t?

Key specs include a powerful servo system, machine weight of 4 tons, 5.5 kW motor, ejector force of 100 kN, ejector return force of 160 kN, slide stroke of 450 mm, and overall dimensions of 1570 mm × 850 mm × 2650 mm.

3. Which applications is this press suitable for?

The YKT series is suitable for machine tools, construction machinery, electrical components, bearings, washing machines, auto parts, motor parts and powder metallurgy—particularly for automated, large-scale production of compacted parts.

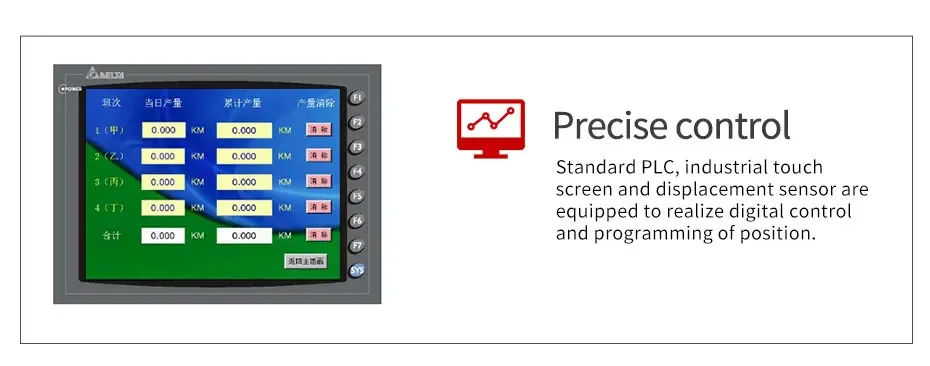

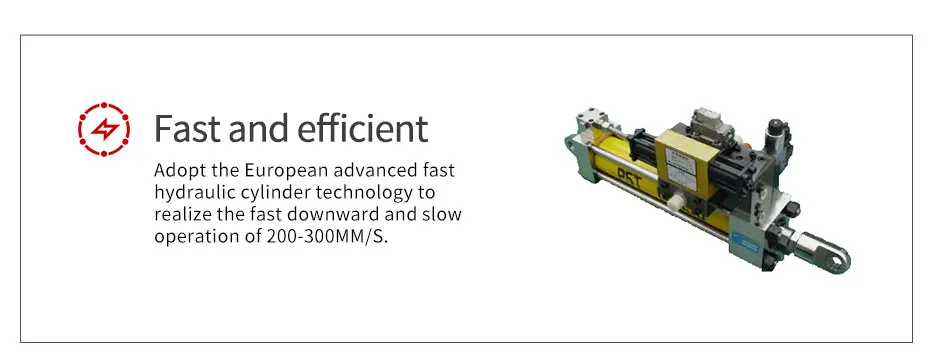

4. What advantages does the servo system provide?

The servo system delivers precise motion control, improved energy efficiency, repeatable compaction profiles, and faster, more consistent cycle-to-cycle performance compared with purely hydraulic or mechanical systems.

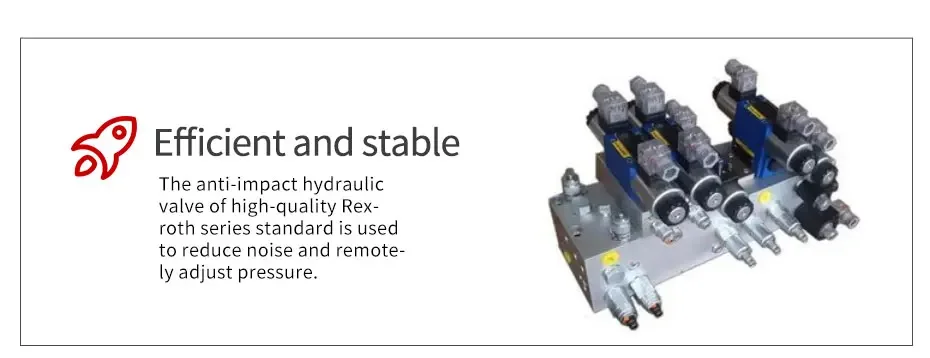

5. What core components are included in the press?

The machine is built with high-quality core components, including the main motor, hydraulic pump, PLC control system and the servo drive, all selected for durability and reliable operation.

6. What warranty and after-sales support are provided?

The YKT-50t comes with a 2-year warranty. After-sales service includes free spare parts and supplier support for maintenance and technical issues during the warranty period.

7. What are the machine's footprint and installation dimensions?

Overall machine dimensions are 1570 mm (W) × 850 mm (D) × 2650 mm (H). For final installation planning, account for additional clearance for operation and maintenance as recommended by the supplier.

8. What electrical/power requirements does the press have?

The press is equipped with a 5.5 kW motor. Exact electrical supply (voltage, phase, breaker sizing) depends on the local configuration—please consult the machine's electrical datasheet or contact the supplier for site-specific requirements.

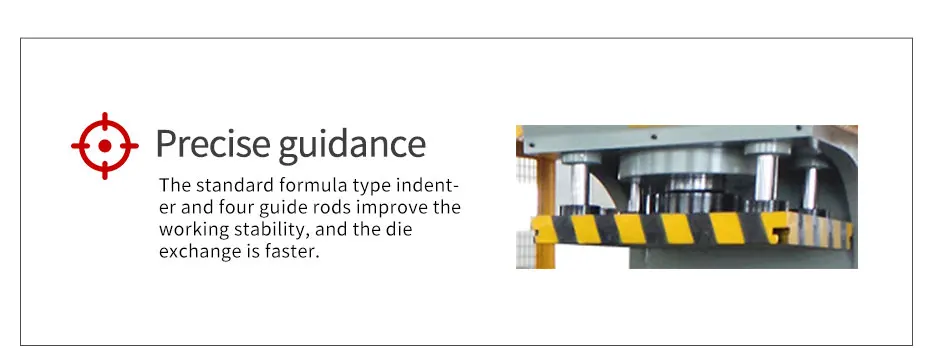

9. Can the machine handle different part sizes and materials?

Yes. With a 450 mm slide stroke and adjustable slide working speed, the press accommodates a variety of part sizes and powder materials commonly used in powder metallurgy and related industries.

10. What is the production speed or cycle capability?

Working speed of the slider is adjustable (series range typically 7–15 mm/s). Exact cycle time depends on part geometry, compaction profile and tooling; contact the supplier with part details for estimated cycle rates.

11. What maintenance is recommended for reliable operation?

Routine maintenance includes regular lubrication, inspection of hydraulic and electrical systems, checking fasteners, PLC backups and periodic replacement of wear parts. The supplier can provide a maintenance schedule and support parts list.

12. Are spare parts readily available?

Yes. The product offering includes free spare parts during the warranty period and supplier support for sourcing replacement parts after warranty—contact after-sales for availability and lead times.

13. Is the press configurable or available with optional features?

The description indicates high-quality core components and automation. For specific options (tooling, safety guards, custom PLC programs, auxiliary equipment), contact the manufacturer or sales representative for available configurations and quotations.

14. Does the machine meet safety or compliance standards?

Specific safety certifications are not listed in the provided description. Please consult the supplier for information on standard safety features, available guarding/interlocks and compliance with regional standards (CE, UL, etc.).

15. How can I get more information, a quote or technical drawings?

Contact the manufacturer or authorized distributor with your application details (part drawings, expected production volume, electrical supply). They can provide detailed quotes, technical specifications, tooling recommendations and installation drawings.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading