B21, China Town Mall, Midrand

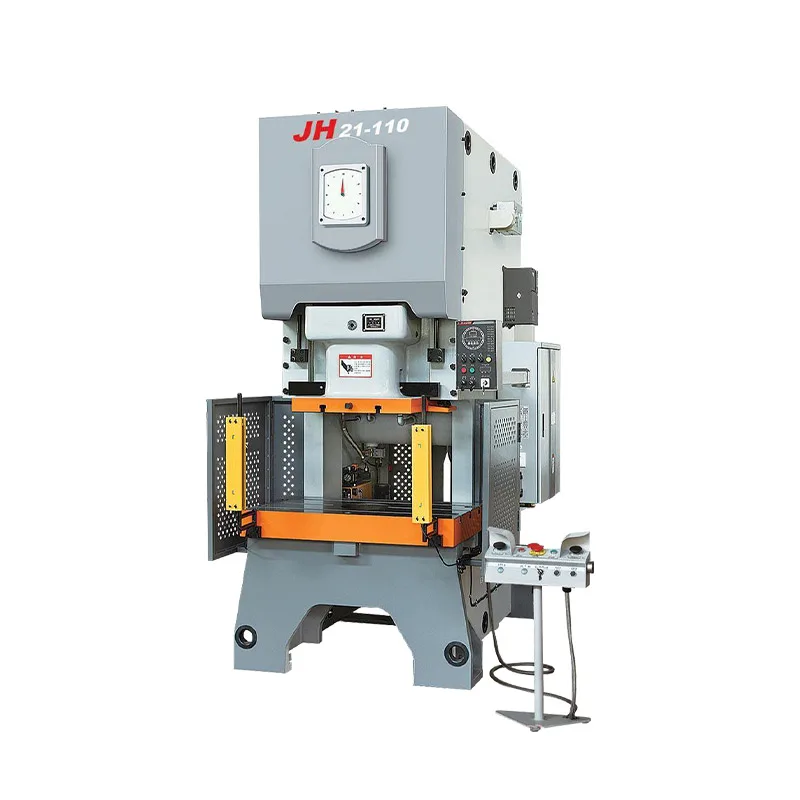

JH21 C frame 80ton form mold pneumatic hydraulic press punch machine hole punching press machine

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 60522474464

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the rated capacity of the JH21 C frame press?

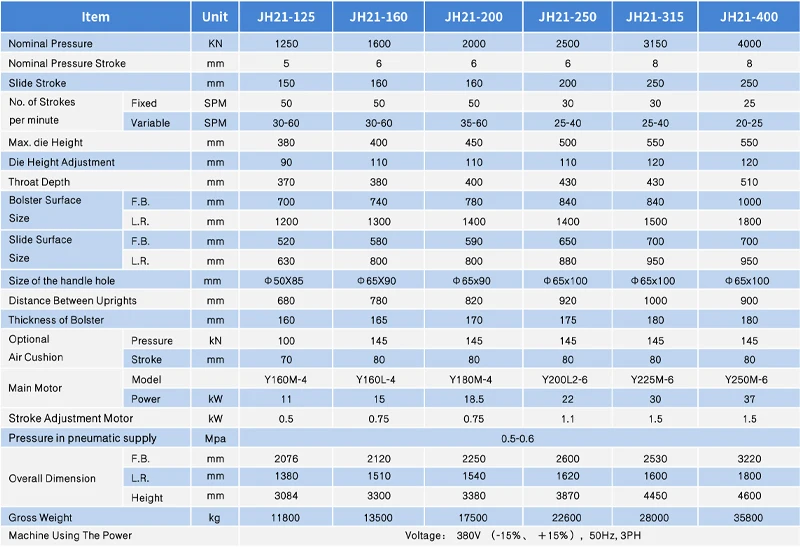

The model described is an 80-ton C-frame press, designed for medium to heavy plate processing tasks such as cutting, punching, blanking, bending and light stretching.

2. What types of operations can the JH21 Series perform?

The JH21 Series is versatile and suited for cutting, punching, blanking, bending and light stretching of plate materials.

3. What is the frame design and how does it affect performance?

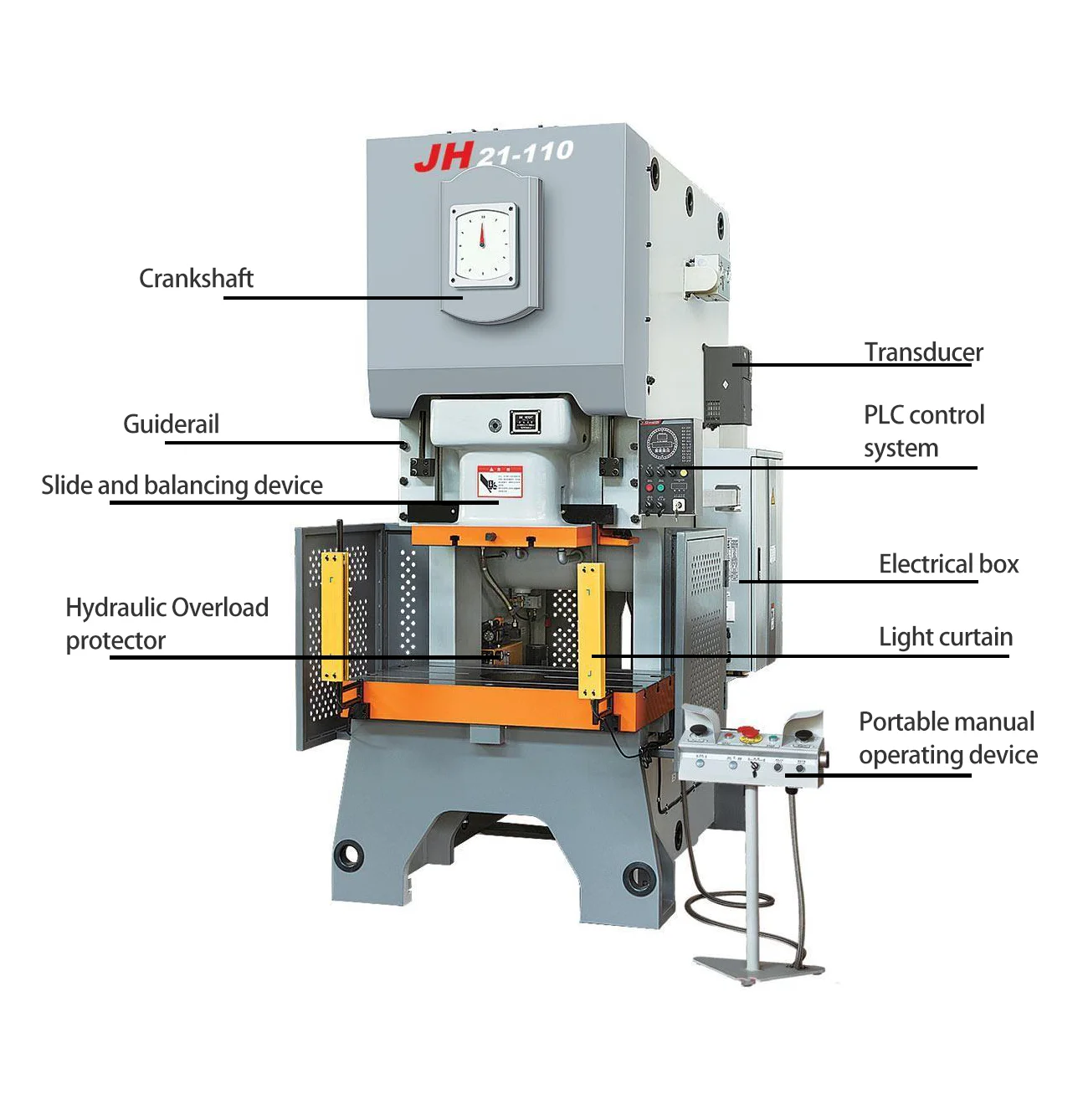

It uses a C-type steel-welded frame that provides high rigidity and minimal deformation. The compact C-frame reduces vibration, improving accuracy and prolonging machine life.

4. How is guiding precision achieved on this press?

Precision guiding is provided by a lengthened hexahedral rectangular gib, which ensures accurate alignment of the slide and stable, repeatable operation.

5. What kind of clutch and brake does the press use?

The press uses a low-inertia combined dry pneumatic friction clutch and brake from OMPI (Italy), delivering smooth engagement, easy maintenance and reliable safety.

6. Is there a hydraulic system in this machine?

The JH21 Series is primarily a mechanically driven press with pneumatic control elements (clutch/brake and balance cylinders). If you require hydraulic actuation or additional hydraulic features, consult RAYMAX for available customizations or model variants.

7. How does the integrated gear system extend gear life and reduce noise?

The driving gears are rigidly supported and operate submerged in an oil bath inside the frame. This reduces shaft deflection, lowers operating noise, and improves gear longevity.

8. What safety systems and certifications are included?

The press includes protective fencing, safety interlocks, front-side covers with switches, backlight safety guards (Category-4), dual-valve and pneumatic dual balance cylinder, and meets CE electrical standards. Controls and emergency stop features comply with relevant safety and OSHA-style hand/foot control requirements.

9. What electrical and control components are used?

The electrical panel uses SIEMENS automation and electrical equipment and incorporates a cooling system. Synchronous detection is handled by a cam controller and Schneider proximity switch. Control options include two-hand buttons and a foot switch.

10. Is stepless speed control available?

Yes — the standard design uses mechanical gearing, but customers can opt for an electromagnetic governor to enable stepless speed regulation.

11. Does the press have automatic lubrication?

Yes, the JH21 Series is equipped with an auto grease lubrication system to ensure consistent lubrication and reduce routine maintenance tasks.

12. What maintenance is recommended?

Routine maintenance includes checking and replenishing gear oil in the oil bath, servicing the pneumatic clutch/brake, inspecting the auto-lubrication system, verifying safety interlocks and guards, and periodic inspection of gibs and tooling alignment. Follow the manufacturer's maintenance schedule for intervals and procedures.

13. What tooling is compatible and how easy is stroke adjustment?

The press accepts standard punch-and-die tooling appropriate for C-frame presses. It features an easy stroke adjustment mechanism to set press stroke and die clearance for different operations. For specific tooling dimensions and capacities consult the RAYMAX tooling guide.

14. What site requirements are needed for installation?

Typical requirements include a level, reinforced foundation or floor capable of bearing the machine weight and reaction forces, appropriate electrical supply as per the machine specification, compressed air supply for pneumatic systems, and adequate clearance for maintenance and safety guarding. Contact RAYMAX or your distributor for the detailed site-prep checklist and electrical/pneumatic specifications.

15. Are training, warranty and customization options available?

RAYMAX and its authorized distributors generally offer operator and maintenance training, warranty packages, and options for customization (electromagnetic governor, tooling, control upgrades, etc.). For exact terms, warranty length and available options, contact RAYMAX sales or your local distributor.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading