B21, China Town Mall, Midrand

ITECH Automatic LED Pcb Making Machine Desktop Smt Pick And Place Machine Chip Mounter With 4 Camera For Smd Pcb Assemble Line

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600616319025

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 10 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the mounting precision of the ITECH PPM-A320VB?

The ITECH PPM-A320VB has a mounting precision of 0.025mm, ensuring high accuracy in component placement.

2. What types of components can the PPM-A320VB handle?

The PPM-A320VB can handle various components including resistors, capacitors, LEDs, and SMDs such as SOT, SOP, QFN, and BGA.

3. What is the maximum mounting speed of this machine?

The machine can mount components at a speed of up to 5500 pcs/hour.

4. Is the machine suitable for small batch production?

Yes, the PPM-A320VB is designed for proofing and small batch production, combining flexibility and high accuracy.

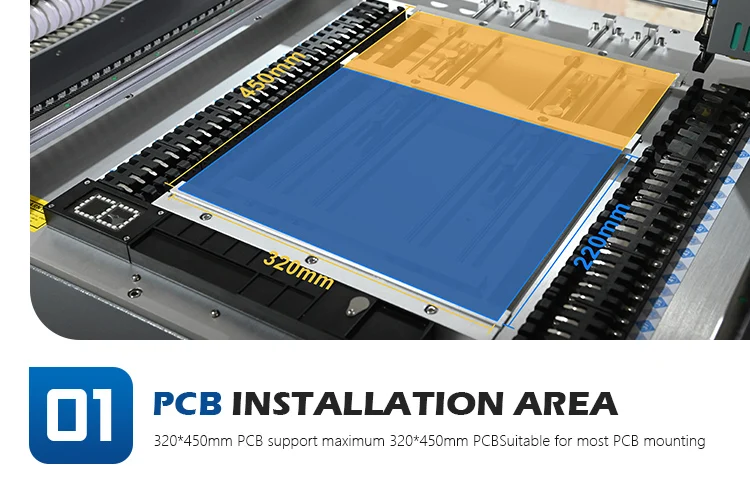

5. What is the size range of PCBs that the machine can accommodate?

The PPM-A320VB can handle PCBs with a minimum size of 10×10mm and a maximum size of 320×450mm.

6. Does the machine support dual-head operation?

Yes, the PPM-A320VB features dual-head operation, allowing two components to be placed simultaneously for increased efficiency.

7. What software does the PPM-A320VB use?

The machine operates on a Microsoft Windows 7 PC system with operational software for R&D purposes.

8. Can I use my own program files with this machine?

Yes, the PPM-A320VB supports CSV and TXT file formats, allowing for easy integration with existing production files.

9. What is the weight of the PPM-A320VB?

The machine weighs approximately 85kg.

10. What is the maximum height of SMD components that can be used?

The machine can handle SMD components with a height of up to 5.5mm, and it can be customized for a maximum height of 11mm.

11. How many parts cameras does the machine have?

The PPM-A320VB is equipped with 3 parts cameras and 1 PCB camera for accurate placement and recognition.

12. What is the air pressure requirement for the machine?

The air pressure requirement for the PPM-A320VB is 0.4 Mpa.

13. Is the Z-axis movement customizable?

The Z-axis moving range is 10mm with a rotation angle of 0 to 360°, accommodating various component placements.

14. How many feeder stations does the machine have?

The PPM-A320VB features 54 independent feeder stations for a diverse range of component types and sizes.

15. What type of camera system is used in the machine?

The machine features an industry-standard camera vision system with high-resolution CCD cameras for accurate placement.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading