B21, China Town Mall, Midrand

Injection Molding Machine Cadona Concrete Block Machine

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600182554212

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Injection Molding Machine Cadona Concrete Block Machine?

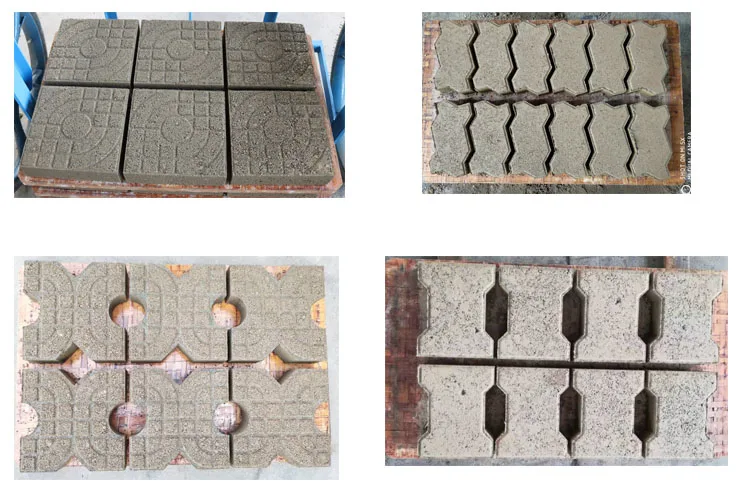

The Cadona is a fully automatic, hydraulic concrete block injection molding machine with PLC control. It is designed to produce hollow and solid blocks, color paving blocks and curbstones with high output and easy operation.

2. What model and main technical specifications does this machine have?

Model: QTJ4-18. Motor power: 20.5 kW (power distribution suggested 40 kW). Weight: 5,000 kg. Overall size: 3700 × 2100 × 2700 mm. Forming cycle: 20–25 seconds. Vibrating force: 60 kN. Down pressure: 4–7 tons. Pallet size: 850/880 × 550 × 20 mm.

3. What raw materials can the machine use?

It can use cement, concrete, sand, fly ash, construction waste, slag and mountain flour (local stone powder).

4. What is the recommended raw material ratio?

Typical proportions: cement 8%–10% of the mix. A commonly used approximate ratio by volume is cement : sand : stone ≈ 1 : 4 : 5.

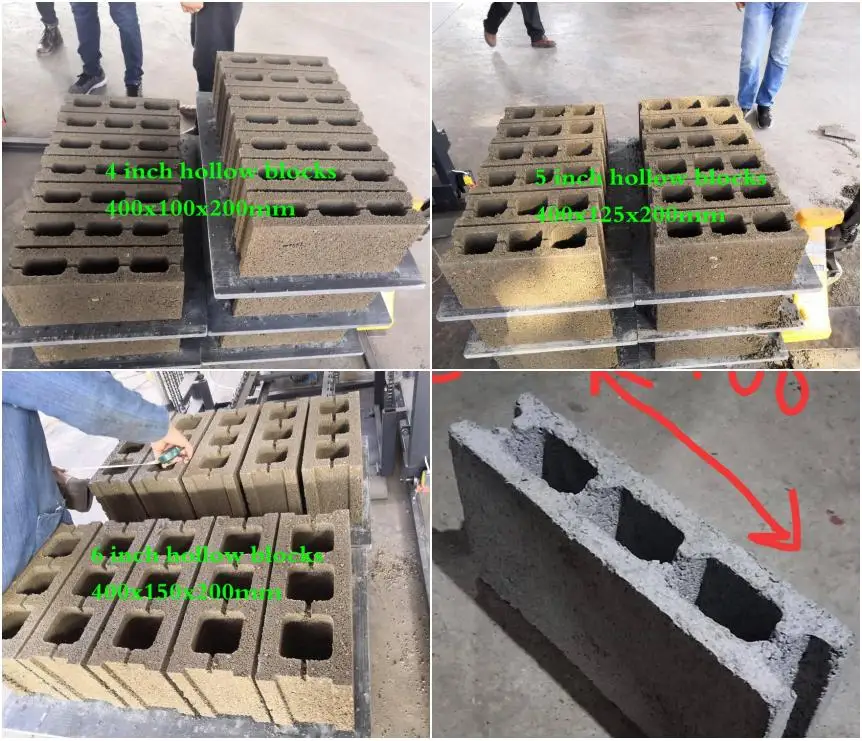

5. What block types and sizes can the machine produce?

It can produce hollow and solid blocks, color paving blocks and curbstones in a variety of sizes. Common sizes listed include 400×200×200 mm, 400×150×200 mm, 400×100×200 mm, 400×250×200 mm and many smaller formats; molds can be changed to make other sizes and shapes.

6. What are the typical weights of common hollow blocks?

Example hollow block weights from the specification: 400×200×200 mm ≈ 17 kg; 400×150×200 mm ≈ 13.5 kg; 400×100×200 mm ≈ 10 kg.

7. What production capacity can I expect?

Capacity depends on block size and number of cavities per mould. Typical examples from the machine data: 400×150×200 mm — 5 pcs/mould, ~1,200 pcs/hour, ~9,600 pcs/8 hr; 400×200×200 mm — 4 pcs/mould, ~960 pcs/hour, ~7,680 pcs/8 hr; 400×100×200 mm — 7 pcs/mould, ~1,680 pcs/hour, ~13,440 pcs/8 hr; 400×250×200 mm — 3 pcs/mould, ~720 pcs/hour, ~5,760 pcs/8 hr. (Actual output varies with mix, cycle time and operator efficiency.)

8. How much workshop/installation space and utilities are required?

Recommended installation area: 2,600–3,300 m². Workshop area: ~80 m². Raw material/workshop area: ~400 m². Office: ~50 m². Staff: 5–6 people. Power distribution: ~40 kW available. Water consumption: about 5 tonnes/day.

9. How many pallets does the production line require and what are their specs?

The spec indicates around 1,500 pallets are required for continuous operation. Pallet size is 850 or 880 × 550 × 20 mm (depending on tooling).

10. Is the machine easy to operate?

Yes — the machine is equipped with a PLC control box for automated cycles and easy operation. Controls are intended to be user-friendly, but operator training is recommended.

11. Can I use recycled construction waste or slag in the mix?

Yes. The machine specification lists construction waste and slag among acceptable materials. Proper processing and grading of recycled materials is important to ensure block strength and consistent quality.

12. What maintenance and spare parts should I plan for?

Regular maintenance includes checking hydraulic oil and filters, vibration system inspection, greasing moving parts, checking pallets and moulds for wear, and monitoring electrical/PLC connections. It's advisable to stock wear parts such as spare pallets, seals, liners, vibration elements and common hydraulic components.

13. Does the supplier provide installation, commissioning and training?

Most suppliers of this type of machinery provide installation, commissioning and operator training — confirm service scope with the seller. Professional installation and initial training are recommended to reach optimal performance quickly.

14. Can the machine be customized (different block sizes, colors or moulds)?

Yes. Moulds can be customized for different block sizes, patterns and colors. Color paving blocks require pigment added to the mix; discuss specific customization, tooling lead times and costs with the supplier.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading