B21, China Town Mall, Midrand

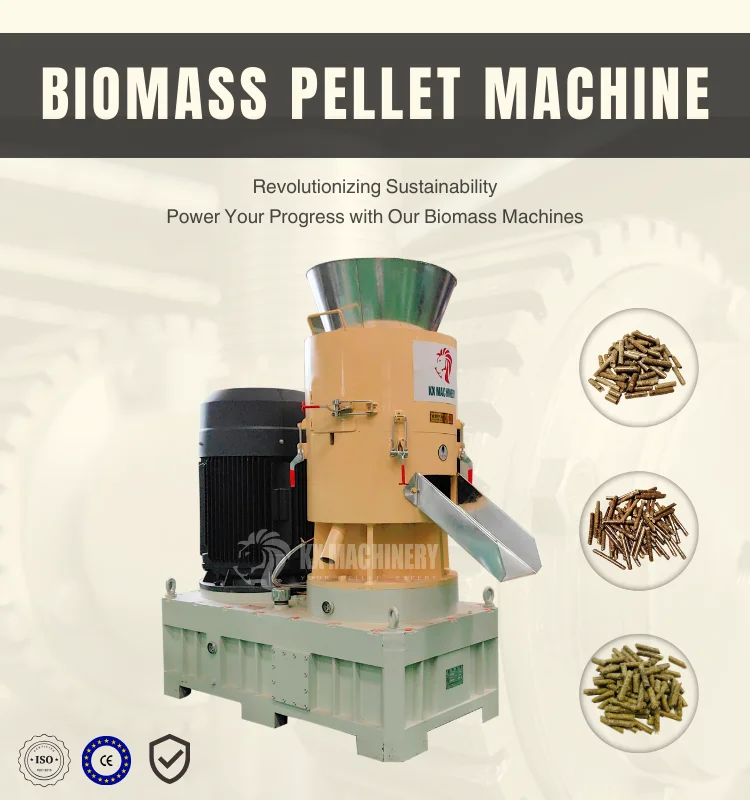

Industrial Wood Sawdust Pellets Making Machine Fuel Burning Pellets Making Mill Automatic Wood Pellet Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600834545834

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Industrial Wood Sawdust Pellets Making Machine and what does it do?

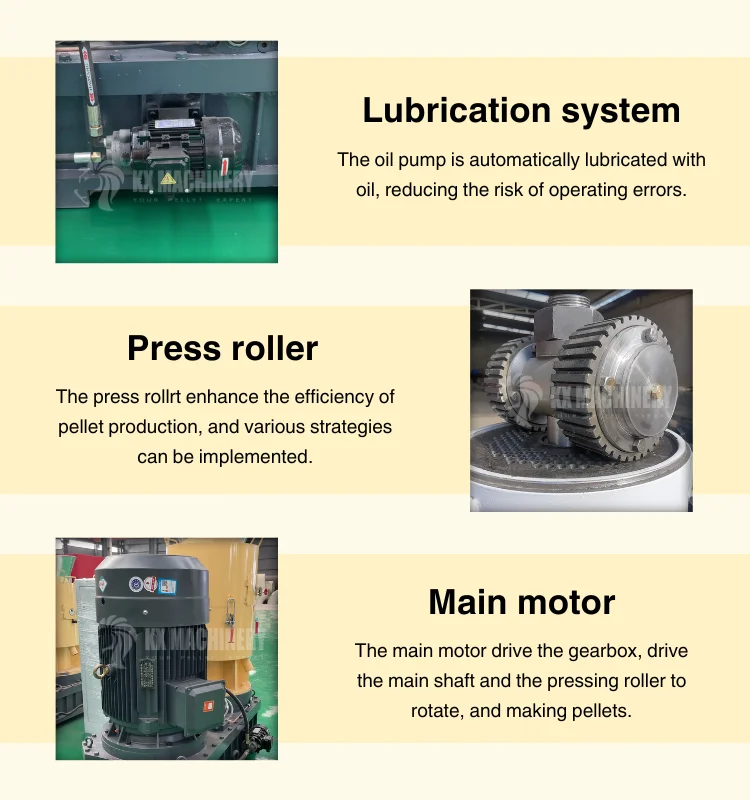

This is a flat-die industrial pellet mill that converts biomass and agricultural waste (sawdust, straw, rice husk, corn stalks, peanut shells, etc.) into high-density fuel pellets or fertilizer granules for burning or reuse. It uses an integrated closed gearbox and a rotating press roller with a stationary flat die for continuous pelletizing.

2. What raw materials can this pellet machine process?

It processes a wide range of biomass and fertilizer wastes: wood chips/sawdust, bamboo, palm, corn/cotton stalks, straw, rice husks, peanut shells, sunflower, alfalfa, paper, animal manure and many other plant or fertilizer wastes.

3. What machine models, motor powers and capacities are available?

Available models from the specification: F200 — 7.5 kW, 80–150 kg/h, 420 kg; FD260 — 15 kW, 100–200 kg/h, 500 kg; FD300 — 22 kW, 200–300 kg/h, 800 kg; FD350 — 30 kW, 300–400 kg/h, 900 kg; FD400 — 37 kW, 400–600 kg/h, 1000 kg; FD450 — 45 kW, 600–800 kg/h, 1500 kg; FD550A — 55 kW, 700–1000 kg/h, 1800 kg; FD550B — 75–90 kW, 1000–1200 kg/h.

4. What pellet diameters can the machine produce?

Flat-die pellet mills typically produce pellets in common diameters (for example 6, 8 or 10 mm). Die hole size can often be customized — confirm available die sizes with the supplier for your target pellet diameter.

5. What is the required moisture content and particle size of raw material?

Recommended moisture content is low — generally 8–15% (optimal around 10–12%) for best pellet quality and compression. Feedstock should be ground to a fine and uniform size (recommended below about 3–5 mm) to ensure smooth pressing and consistent pellets.

6. Does the material need pre-processing (grinding/drying/batching)?

Yes. Materials should be shredded or milled to the recommended particle size and dried to the correct moisture range. Some materials may also require blending, pre-compaction or addition of a binder to improve pellet strength and durability.

7. Is this machine automatic and suitable for continuous operation?

The design is for automatic pelletizing with vertical feeding and continuous operation. Small-capacity models are suited to small factories, home users or boiler heating systems; feeding options and automation level can be adapted to your needs.

8. Can the machine make both fuel pellets and fertilizer granules?

Yes. The machine can press biomass fuel pellets and also produce fertilizer granules from suitable fertilizer wastes (animal manure, plant waste and certain chemical/processed fertilizer materials), provided the feed is prepared correctly.

9. How does the machine handle light or fluffy biomass that is hard to compact?

The rotating press roller with a stationary flat die and vertical feeding design helps to prevent fluffiness by ensuring the material is pressed firmly into the die. Proper pre-processing (moisture control, grinding, possible pre-compression) further reduces fluff and improves throughput and pellet quality.

10. What routine maintenance is required?

Regular maintenance includes lubrication of bearings and gearbox per the manual schedule, periodic inspection and replacement of the die and rollers when worn, cleaning residue from the die and feed system, checking belt/bearing tension and electrical connections, and addressing any abnormal noise or vibration promptly.

11. What power supply and electrical requirements does the machine have?

Each model is driven by the listed motor power (see model specs). These are industrial three-phase motors; specific voltage and frequency options (e.g., 380V/50Hz or 400V/60Hz) should be confirmed with the supplier to match your local supply.

12. What pellet quality and uses can I expect (for fuel burning)?

When properly processed, pellets are high-density, low-moisture fuel suitable for domestic and industrial pellet stoves and boilers. Good pellets burn efficiently with stable calorific output; storage in dry conditions preserves quality.

13. Are spare parts, installation and after-sales support available?

Typically suppliers provide spare parts (dies, rollers, bearings), installation guidance, operation manuals and training. Warranty terms and after-sales support vary — confirm the exact package, spare parts availability and lead times with the vendor before purchase.

14. What common troubleshooting tips should I know?

Low output or poor pellet quality is usually caused by wrong moisture content, oversized feed particles, worn die/rollers, or incorrect feed rate. Overheating can be caused by insufficient lubrication or excessive load. Address these by adjusting moisture/grind size, replacing worn parts, ensuring proper lubrication and matching feed rate to machine capacity.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading