B21, China Town Mall, Midrand

Industrial Lithium Salt Separating Plate Type Centrifugal Machine Automatic Unloading Centrifuge Separator for Solid Liquid

- Section : Machinery

- Category : Separation Equipment

- SKU : 1600674941767

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

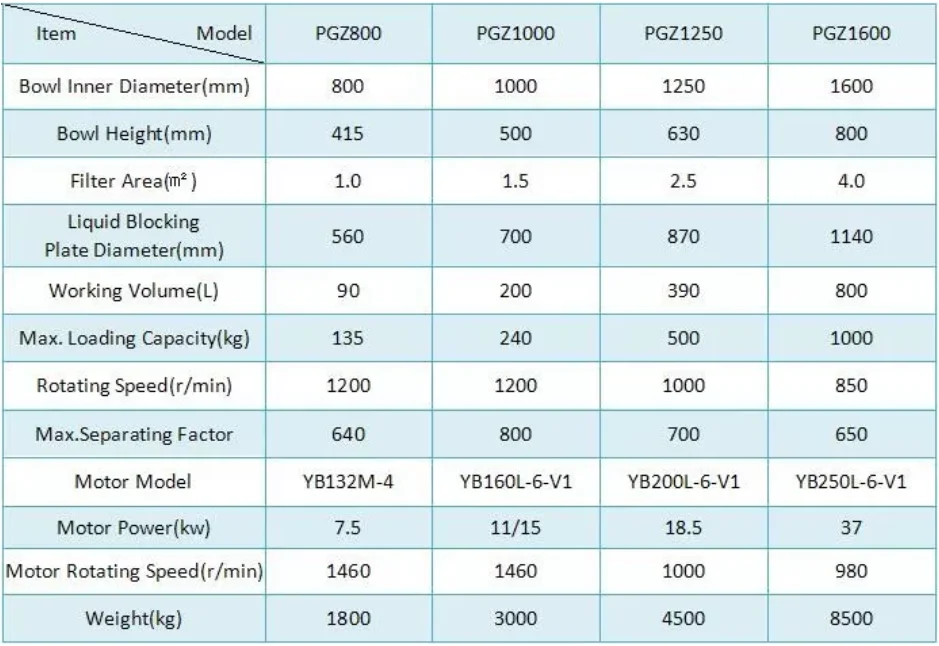

1. What is the maximum loading capacity of the WEST TUNE High-Performance Separator?

The WEST TUNE High-Performance Separator has a maximum loading capacity of 135 kg.

2. What type of materials can the separator handle?

The separator is designed to handle high-density, toxic, harmful, flammable, and explosive media, making it suitable for a variety of industrial applications.

3. What is the inner diameter of the bowl in the separator?

The inner diameter of the bowl is 800 mm, allowing for effective separation.

4. How does the liquid blocking plate function?

The liquid blocking plate, with a diameter of 560 mm, effectively filters out unwanted particles during the separation process.

5. What is the filter area of the separator?

The separator features a large filter area of 1.0 m², which maximizes the efficiency of the separation process.

6. What is the operating speed of the separator?

The separator rotates at an adjustable speed of 1200 r/min, achieving a maximum separating factor of 640 for precise separation.

7. What material is the drum made of?

The bottom of the drum is made of cast ladle lined with 316L stainless steel, providing durability and corrosion resistance.

8. Is the separator suitable for pharmaceutical applications?

Yes, the separator is widely used in pharmaceutical applications for the liquid-solid separation of raw materials, intermediates, and finished products.

9. What type of motor is used in the separator?

The separator is equipped with a powerful 7.5 kW motor that operates at 1460 r/min for reliable performance.

10. What industries can benefit from using this separator?

Industries such as food, chemical, pharmaceutical, and those involved in national defense can benefit from this high-performance separator.

11. How is the separator constructed for durability?

The separator is built with high-quality components, including a robust shell of 316L stainless steel and various parts made from corrosion-resistant materials.

12. What is the working volume of the separator?

The separator has a generous working volume that accommodates up to 90 liters for extensive processing capabilities.

13. Can the separator be used for flammable materials?

Yes, the separator is designed to safely handle flammable materials as part of its industrial applications.

14. What surface treatment is applied to the stainless steel?

The stainless steel surfaces are fully polished, with an outer polishing degree of ≤ 0.6um and material contact inner surface of less than 0.4um.

15. How does the separator improve productivity?

The WEST TUNE High-Performance Separator is engineered for optimal performance, ensuring high productivity and reliability in various industrial applications.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading