B21, China Town Mall, Midrand

HZPK Automatic Granule Filling and Sealing Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600835078707

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the HZPK Automatic Granule Filling and Sealing Machine used for?

It is an automated packaging machine designed to form bags (from film), accurately fill granules (1–100 g), seal, cut and count finished packages — ideal for foods (sugar, salt, spices, grains), chemicals, hardware granules and some pharmaceutical granules/pills.

2. What filling range and accuracy does the machine achieve?

Filling range is 1–100 g (customizable). Standard filling accuracy is ±0.2 g, achieved via vibration feeding and electronic weighing.

3. What packaging materials and bag types are supported?

Supports plastic films, aluminum foil, filter paper and similar materials. Standard models offer three-side seal; back-side (fin) seal, four-side seal and other sealing forms are available via customization.

4. What bag and film size ranges can the machine handle?

Standard bag width: 50–90 mm; bag height: 50–150 mm; film width: 50–200 mm. If you need different sizes, forming structures and machine configuration can be customized.

5. What is the production speed and electrical requirement?

Packing speed is typically 5–25 bags per minute (depends on product and settings). Electrical requirement is 220 V, 50–60 Hz with total power ≤1.5 kW.

6. What control and adjustment features does the machine have?

Controlled by a microcomputer with simple button interface. Sealing temperature, film pulling speed, interval time and other parameters are adjustable for process optimization.

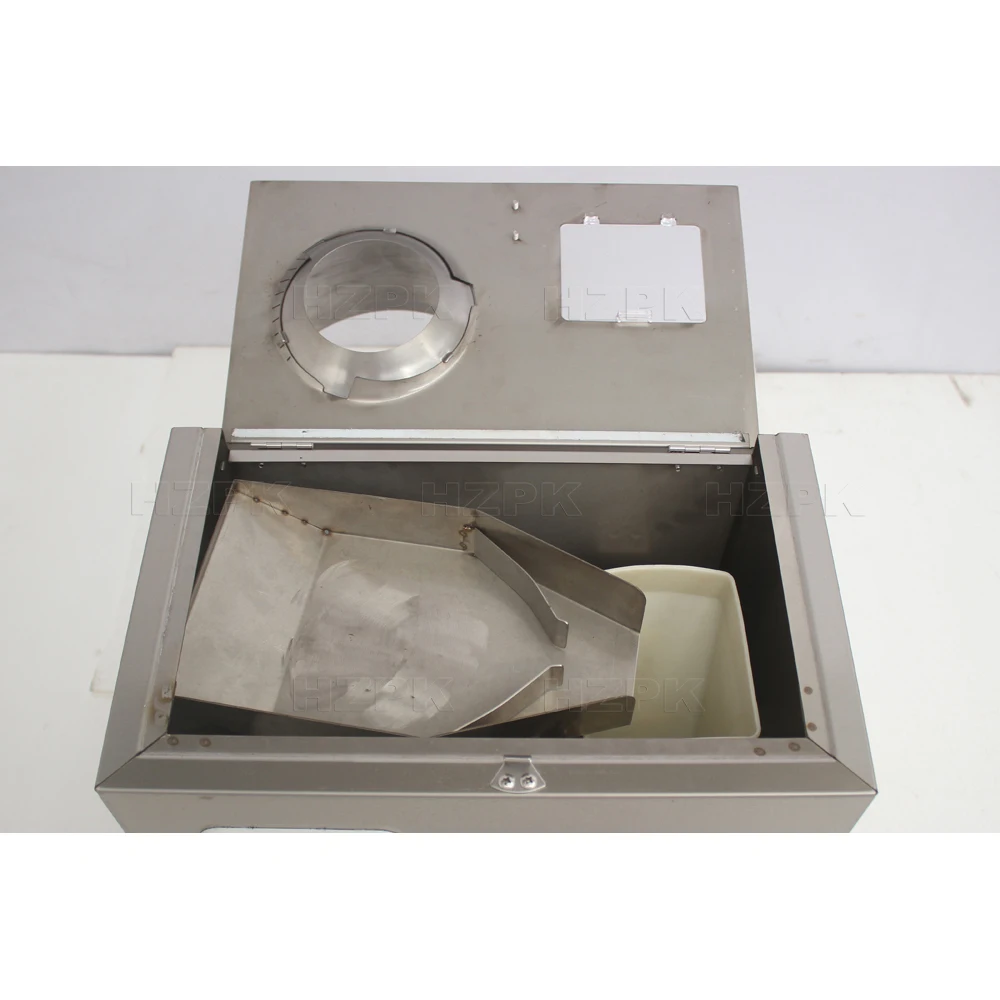

7. What are the machine dimensions and construction materials?

Typical machine footprint is 52 × 65 × 165 cm. The body and contact parts use food-grade stainless steel (304 on vibrating plate and many contact areas) for durability and easy cleaning.

8. Does the machine provide counting and display functions?

Yes — it displays weight, counts packages automatically and can track output for batch control and production records.

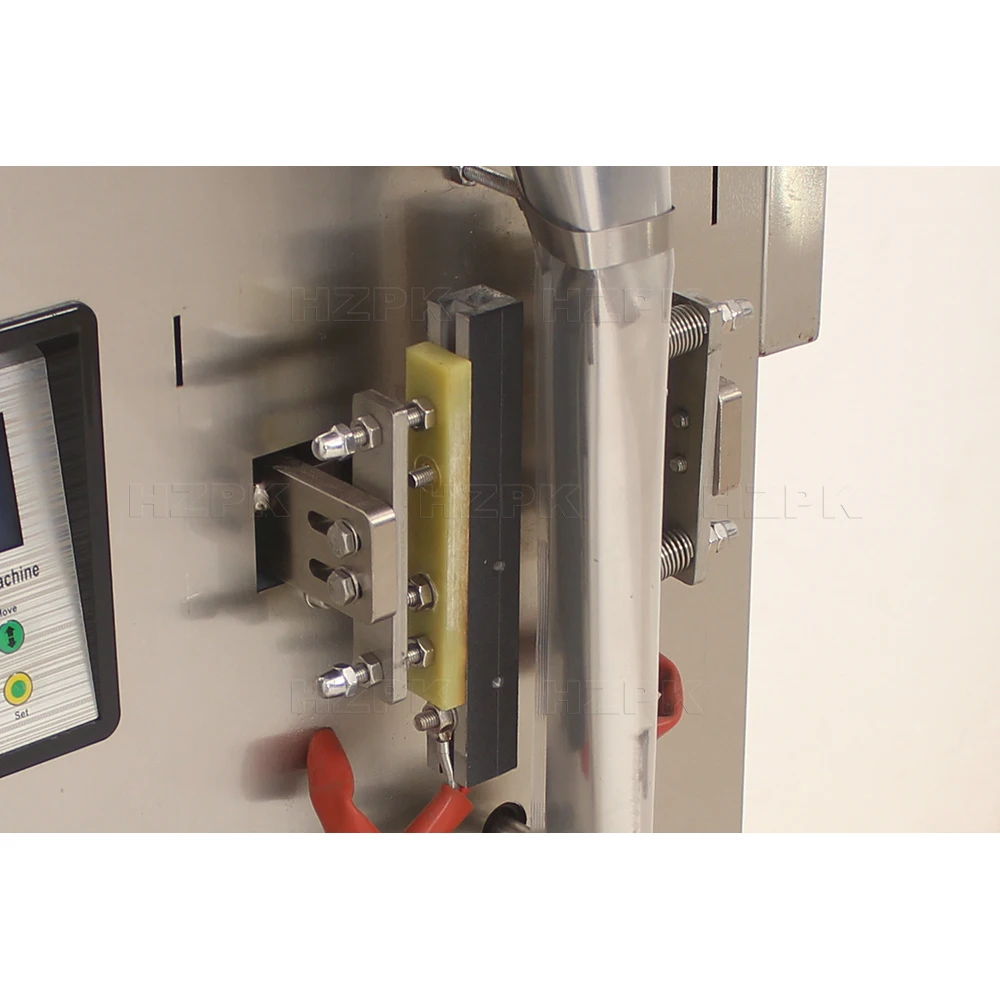

9. What kinds of sealing and cutting are used?

The machine performs vertical sealing, horizontal sealing and automatic cutting. Sealing length is adjustable (standard 50–150 mm) and guide-rail structure ensures flat seals.

10. Is maintenance difficult and are spare parts available?

Maintenance is designed to be easy. The machine comes with free spare parts and video technical support; online support is also provided to minimize downtime.

11. Can the machine be customized for specific products or sizes?

Yes. Common customizations include different forming collars for varying film widths, altered filling range, alternative sealing types (back/three/four-side), and adapted vibration settings for specific granules.

12. Is the machine suitable for food and pharmaceutical use?

Yes. The food-grade stainless steel construction and hygienic design make it suitable for food industry use. It can be used in some pharmaceutical applications for granules/pills — please discuss specific regulatory requirements for pharmaceuticals when ordering.

13. What safety features are included?

The machine includes standard industrial safety features such as protective guards and emergency stop functionality. Specific safety options and certifications can be provided on request.

14. What support and training are offered after purchase?

After-sales support includes video technical support, online troubleshooting and free spare parts. On-site installation and training can be arranged upon request (may incur additional charges).

15. How do I order the machine and what information should I provide?

Contact sales with details about the product to be packed (type of granule), desired filling range and accuracy, bag/film sizes, expected output (bags/min or daily throughput), sealing type required and any customization requests. Sales will provide lead time, pricing and shipping details.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading