B21, China Town Mall, Midrand

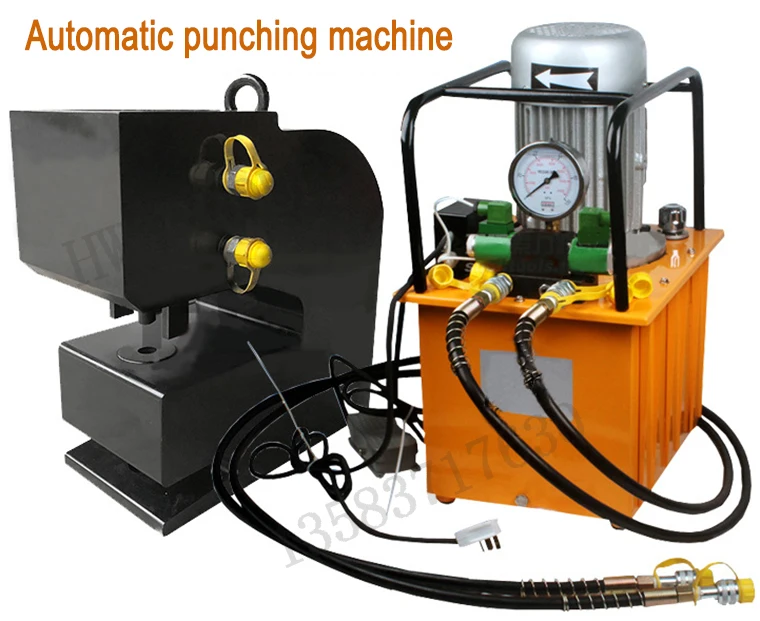

HW Hydraulic Punching Machine

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 62135103057

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the HW Hydraulic Punching Machine?

The HW Hydraulic Punching Machine is a hydraulically driven punching press designed for efficient, flexible and precise hole punching tasks in fabrication and production environments. It's offered in multiple output capacities and configurations to suit a variety of applications.

2. What punching force does the machine provide?

Models range from around 31 tons up to 200 tons of punching force. The described main unit can provide up to 200T for heavy-duty punching; smaller models (e.g., HW-CH60, HW-CH70, HW-CH80, HW-CH100, HW-CH150) offer lower rated forces appropriate to their size.

3. What materials and thicknesses can it punch?

Capacity depends on the model: HW-CH60 ~ up to 6 mm (iron) / 10 mm (steel); HW-CH70 ~ up to 10 mm / 12 mm; HW-CH80 ~ up to 16 mm / 20 mm; HW-CH100 ~ up to 20 mm; HW-CH150 ~ max 25 mm steel; HW-CH200 ~ max 30 mm steel. Actual capacity also depends on hole diameter, die selection and material properties.

4. What are the machine's key dimensions and weight?

The general compact configuration is listed as 500 mm (L) x 500 mm (W) x 400 mm (H) with a representative weight of 380 kg for the heavier 200T-style unit. Weights and exact footprints vary by model — lighter models are substantially smaller.

5. What are the throat depth and slide stroke measurements?

Typical slide stroke is 155 mm. Throat depth varies by model: e.g., HW-CH60 = 95 mm, HW-CH70 = 110 mm, HW-CH80 = 115 mm, HW-CH100 = 125 mm, HW-CH150 ≈ 145 mm, HW-CH200 ≈ 140 mm.

6. What power supply does the machine require?

The machine operates on a 380 V industrial power supply. Confirm phase and amperage requirements with the supplier for your specific model and local electrical standards.

7. Which hole sizes and moulds does the machine support?

Available mould sizes depend on model and tooling set. Examples: HW-CH150 moulds include 22, 25, 28, 32 mm; HW-CH200 moulds include 22, 25, 27, 32 mm. Other models support corresponding die sets — custom dies can often be supplied.

8. How easy is setup and operation?

The machine is designed for straightforward setup and user-friendly operation. Basic setup includes installing tooling/dies, connecting hydraulic and electrical supplies, and adjusting stroke/throat as needed. Operator training is recommended for safe and efficient use.

9. What safety measures should be followed when using the machine?

Always follow standard machine safety: wear PPE (safety glasses, gloves, hearing protection as needed), keep guards in place, use emergency stop and lockout/tagout procedures during maintenance, never reach into the die area while the machine is energized, and ensure operators are trained.

10. What routine maintenance does the HW Hydraulic Punching Machine require?

Regular maintenance includes checking and maintaining hydraulic oil level and cleanliness, inspecting and replacing worn dies, lubricating moving parts per the manual, checking fittings and hoses for leaks, and periodic inspection of safety devices. Follow the manufacturer's maintenance schedule for oil change intervals and detailed procedures.

11. Is the machine portable or fixed installation?

Smaller models are compact and easier to relocate within a shop, but the heavier models (especially 150T–200T units) are substantial in weight and intended for semi-permanent installation on a stable, level surface. Use proper lifting equipment for transport and installation.

12. How is the machine packaged for shipping?

Larger models such as the HW-CH150 and HW-CH200 are packaged in wooden cases for protection during transport. Packaging for smaller models may vary; confirm packing details with the supplier.

13. Are spare parts and tooling available?

Yes — dies, moulds and common spare parts (seals, hoses, valves, filters) are typically available from the manufacturer or authorized dealers. For specific parts or custom tools, contact the supplier with your model and serial number.

14. Can the machine be customized or supplied with additional accessories?

Customization options often include special tooling/dies, different throat depths, automation feeders or material supports. Contact the manufacturer or sales representative to discuss custom tooling, power options, or integration with production lines.

15. What warranty and after-sales support are provided?

Warranty terms and support policies are not specified in the product description. Buyers should confirm warranty length, coverage, and available after-sales support (installation, training, spare parts) with the seller or manufacturer before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading

Square hole puncher hydraulic small cheap hole punching machine for big pressure:

Square hole puncher hydraulic small cheap hole punching machine for big pressure: