B21, China Town Mall, Midrand

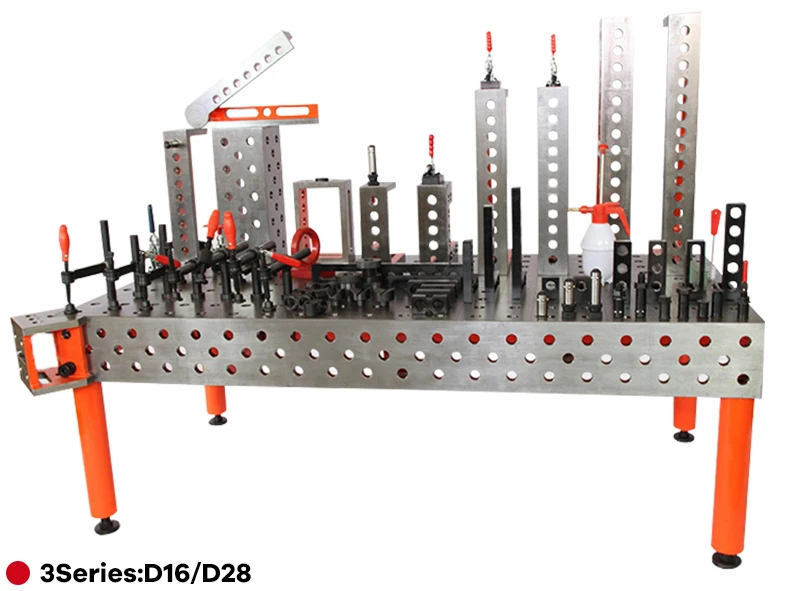

Hoston welding table welding layout table

- Section : Machinery

- Category : Welding Equipment

- SKU : 1600985026078

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Hoston welding table (welding layout table)?

The Hoston welding/layout table is a precision fixture table designed for welding, positioning and layout work. It features a grid of accurately machined holes for locating pins and clamps and is offered in three series (D16, D22, D28) with different hole diameters and grid spacings.

2. What are the differences between the D16, D22 and D28 series?

D16: hole diameter ≈ φ16.065–φ16.149 mm, grid spacing 50 × 50 mm (L1 = 50 ± 0.05 mm). D22: hole diameter ≈ φ22 mm, grid spacing 75 × 75 mm (L1 = 75 ± 0.05 mm). D28: hole diameter ≈ φ28.065–φ28.149 mm, grid spacing 100 × 100 mm (L1 = 100 ± 0.05 mm).

3. What are the dimensional tolerances and flatness specs?

Hole-spacing tolerance: ±0.05 mm (per series L1). Flatness: 0.1 mm per 1000 mm. Verticality: 0.1 mm per 200 mm. Aperture tolerances for D16 and D28 series are provided in the product parameters.

4. What is the surface finish and hardening treatment?

D16 series surface roughness: RA 1.6. D28 series surface roughness: RA 3.2. Tables are nitrided with hardness roughly HV450–HV630 on the treated surface.

5. What is the load-bearing capacity of the table and frame?

Standard tabletop load bearing is 2 tonnes (2T). Frame bearing capacity is 5 tonnes (5T). Always respect these limits and distribute heavy loads evenly.

6. What sizes and part numbers are available?

Sizes vary by series; examples from the spec: PT-1010 (1000 × 1000 × 200 mm), PT-1212 (1200 × 1200 × 200 mm), PT-1515 (1500 × 1500 × 200 mm), PT-4020 (4000 × 2000 × 200 mm). D16 examples include PT-1010D (1000 × 1000 × 100 mm), PT-1515D (1500 × 1500 × 100 mm), PT-2412D (2400 × 1200 × 100 mm). Contact the supplier for the full size/weight list.

7. Can I order custom table sizes, hole patterns or special features?

Yes — custom sizes, hole patterns, hole counts, special frame options and additional machining are commonly available. Contact the manufacturer or distributor with your requirements for a quotation.

8. What materials are used for the tabletop and frame?

The product specification lists a nitrided, hardened surface (HV450–HV630). For exact base-material (cast iron, steel grade, etc.) and full material certificates, please request details from the manufacturer.

9. Are standard clamps and fixturing accessories compatible with the table holes?

Yes. The grid holes are designed for locating pins, clamps and modular fixturing sized to the series nominal diameters (≈16 mm, 22 mm or 28 mm). Use clamps and pins matching the table series for secure fixturing.

10. Can I weld directly on the table surface?

Yes, the table is designed for welding applications, but excessive concentrated heat can damage the surface. Use sacrificial plates, heat sinks, or grounding practices as needed and avoid prolonged localized heating to protect the nitrided layer.

11. How should I lift, move and install the table?

Use appropriate lifting equipment rated for the table weight/size and lift from the frame or specified lifting points — do not lift by the tabletop only. For large tables, use multiple lift points and follow the manufacturer's installation instructions to prevent distortion or damage.

12. What maintenance is required to keep the table accurate?

Keep the surface clean and dry, remove welding spatter and debris promptly, apply a light protective oil to prevent corrosion if needed, and avoid abrasive grinding directly on the surface. Periodically inspect hole wear and flatness; perform rework or re-nitriding through the manufacturer if necessary.

13. Is calibration or flatness certification available?

Yes — most suppliers can provide flatness inspection and certification or supply the table with factory calibration documentation on request. Ask the manufacturer for inspection reports or certification options.

14. What accessories are commonly available for the Hoston welding table?

Common accessories include locating pins, various clamp sets, angle stops, T-slots/adapters, leveling feet, casters, sacrificial plates, welding screens, and modular fixture kits. Availability depends on the supplier.

15. What are the lead time, packaging and warranty details?

Lead time, packaging and warranty vary by table size, customization and order quantity. Contact the seller or Hoston representative for current lead times, shipping packaging options and warranty terms for your specific configuration.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading