B21, China Town Mall, Midrand

Horizontal Automatic Stand Up Bag Yoghurt Packaging Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1601003977678

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

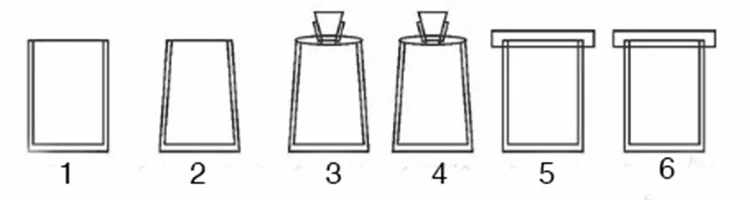

1. What type of pouches does the Horizontal Automatic Stand Up Bag Yoghurt Packaging Machine handle?

It handles premade pouches including doypacks (stand-up pouches), spouted stand-up pouches, 4-side seal bags, paper bags and zipper pouches within the machine's specified size range.

2. What are the maximum and minimum pouch dimensions the machine supports?

Supported bag width is 160–320 mm and length is 160–380 mm. Custom sizes outside this range may require machine modification.

3. What is the production speed of the machine?

The machine operates at 20–40 bags per minute, depending on pouch size, product viscosity and selected options.

4. What filling volume range can the machine handle?

Filling volumes range from approximately 200 ml up to 3000 ml, depending on material characteristics and dosing configuration.

5. Which product types is this machine suitable for?

It's designed for liquid and semi-liquid products such as yoghurt, sauces (ketchup, mayo, dressing), edible oils, shampoos, lotions, conditioners, detergents and similar fluids.

6. What are the machine's power and air supply requirements?

Standard power supply is 380V, 50Hz with 4.5 kW power consumption. Air consumption is about 0.7 m³/min at typical operating pressure. Electrical and pneumatic specs can be adapted on request.

7. What materials and construction standards are used for the machine?

The exterior is stainless steel (SS304) with a carbon steel frame protected by anti-corrosion coatings. Critical parts are mold-fabricated from quality stainless steel (304) and alumina for durability and hygiene.

8. What is the 'No Filling, No Sealing' feature?

The machine will not seal a pouch unless product is detected in it—this prevents empty sealed pouches and reduces material waste and rework.

9. Can the machine print batch numbers, expiry dates or other codes on the pouch?

Yes. An optional date/batch number printing system can be integrated to print production dates, expiry dates, lot numbers or other codes on the pouch.

10. Are reclosable zippers and euro hole punching available?

Yes. Zipper opening (for pre-zippered pouches) and euro hole punching are optional features that can be fitted to meet retail and consumer convenience requirements.

11. How long does it take to change over between different pouch sizes or formats?

Changeover time depends on pouch type and the range of change (e.g., minor vs major size change). Typical changeovers are often between 10–30 minutes; tooling change and operator skill will affect speed.

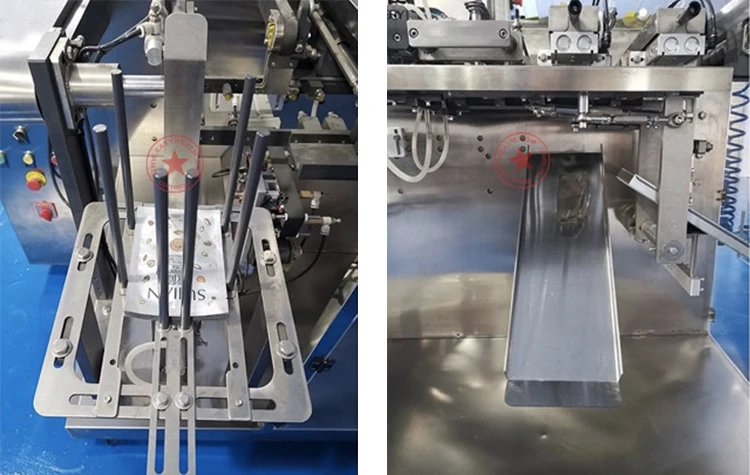

12. What is included in the machine composition and working process?

The system comprises a premade pouch feeding unit, liquid material hopper and dosing fillers. The sequence is pouch pickup, automatic opening, filling, sealing and output of finished pouches.

13. What maintenance and cleaning are required?

Regular cleaning of the hopper and product-contact parts, routine lubrication of moving parts, inspection of seals and heaters, and periodic replacement of wear parts are recommended to maintain performance and food safety.

14. What are the machine's physical size/weight and installation requirements?

Machine weight is about 1500 kg. It requires a stable floor, appropriate electrical and compressed air connections, and adequate space for operator access and maintenance. Exact footprint depends on options and should be confirmed with supplier.

15. Are spare parts, training and warranty/support available?

Yes—suppliers typically provide spare parts, installation assistance, operator training and after-sales support. Warranty terms, service packages and lead times vary by supplier, so request specific details when ordering.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading