B21, China Town Mall, Midrand

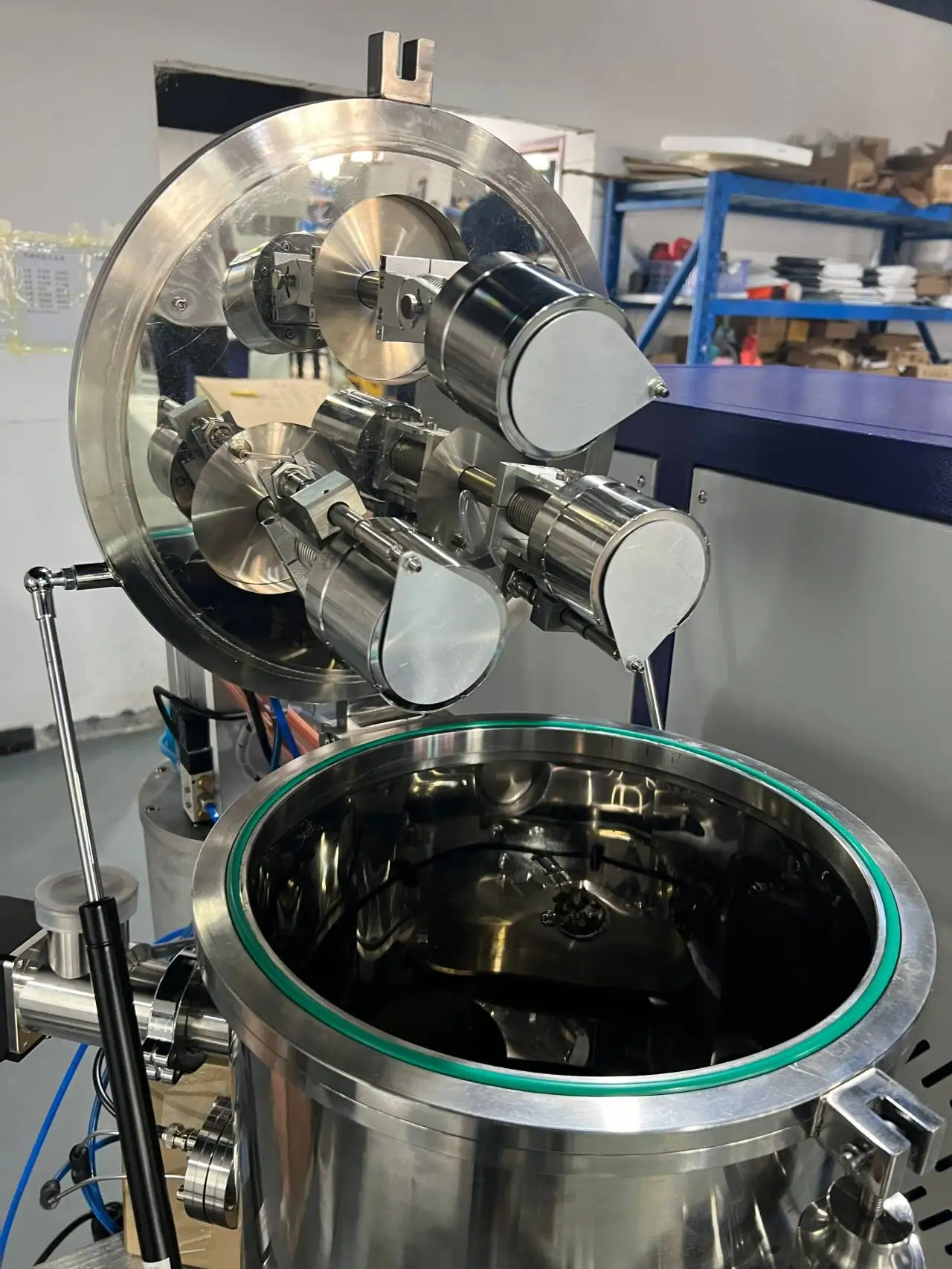

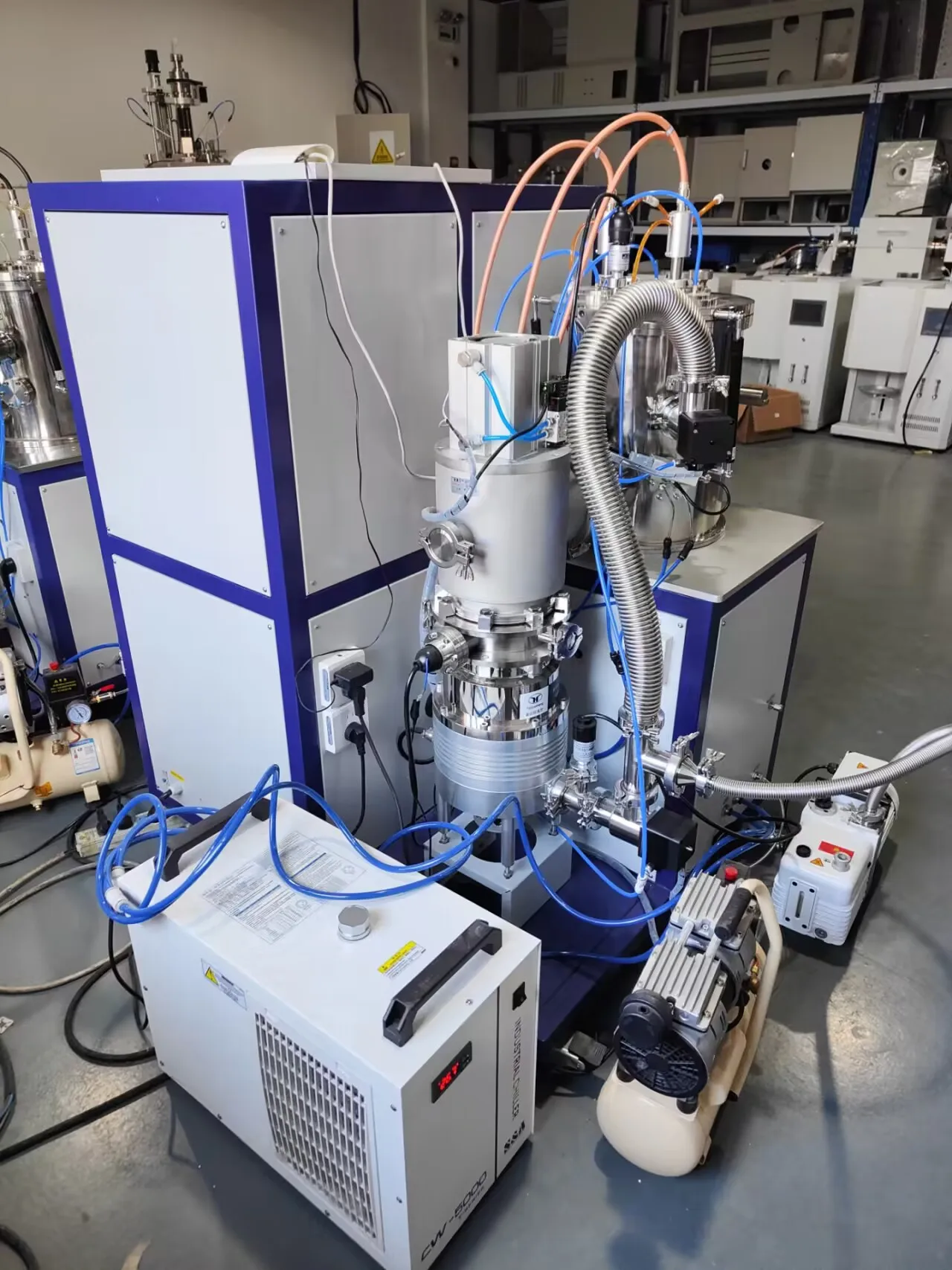

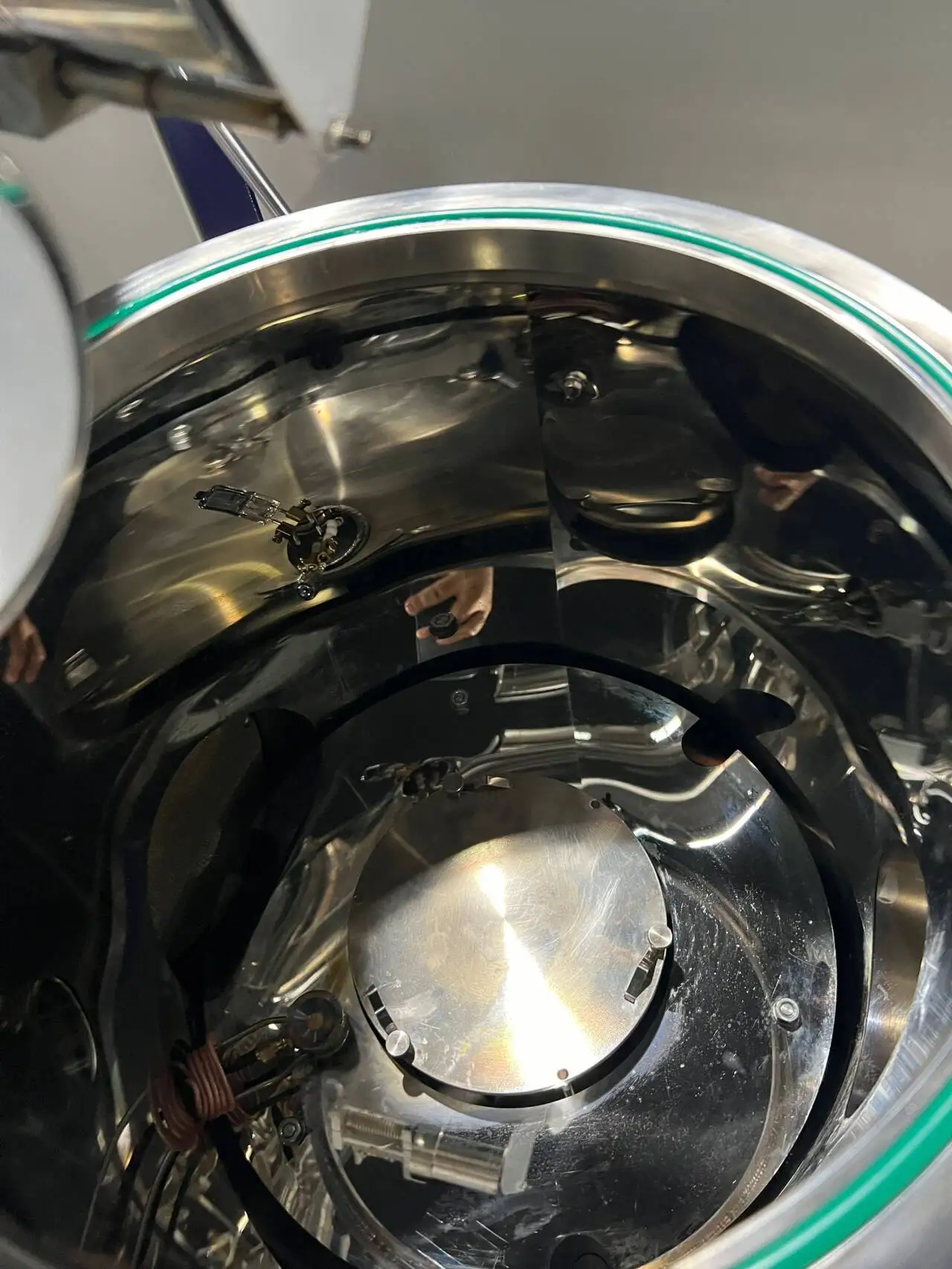

High Vacuum Magnetron Sputtering Deposition System with Quartz Thickness Monitor for Electrode Film

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 1601195487824

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 19 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the main function of the High Vacuum Magnetron Sputtering Deposition System?

The main function of this system is to create high-quality electrode films using a sputtering process, where energetic ions release atoms from a target material that then form a thin film on a substrate.

2. What materials can be deposited using this system?

The system can deposit a variety of materials, including metals, insulators, and semiconductors, thanks to its 500W DC and 500W RF power options.

3. How does the quartz thickness monitor work?

The quartz thickness monitor measures the frequency change of a quartz crystal as material is deposited on it, allowing precise control over the thickness of the film being deposited.

4. What is the maximum heating temperature of the sample stage?

The maximum heating temperature of the sample stage is 500ºC, with a temperature accuracy of ±1ºC.

5. What is the size of the vacuum chamber?

The vacuum chamber has a diameter of 500mm and a height of 500mm.

6. What is the ultimate vacuum level that this system can achieve?

The system can achieve an ultimate vacuum level of 1.0E-5Pa.

7. Can the rotational speed of the sample stage be adjusted?

Yes, the rotational speed of the sample stage can be adjusted between 1 to 20 rpm.

8. Is the system customizable for different target sizes?

Yes, the system is customizable with various target sizes, including 1-inch, 2-inch, and 3-inch options.

9. What type of cooling mode does the system use?

The system uses water cooling to maintain optimal operating temperatures during the sputtering process.

10. How much does the High Vacuum Magnetron Sputtering Deposition System weigh?

The total weight of the system is approximately 350kg.

11. What industries can benefit from this sputtering system?

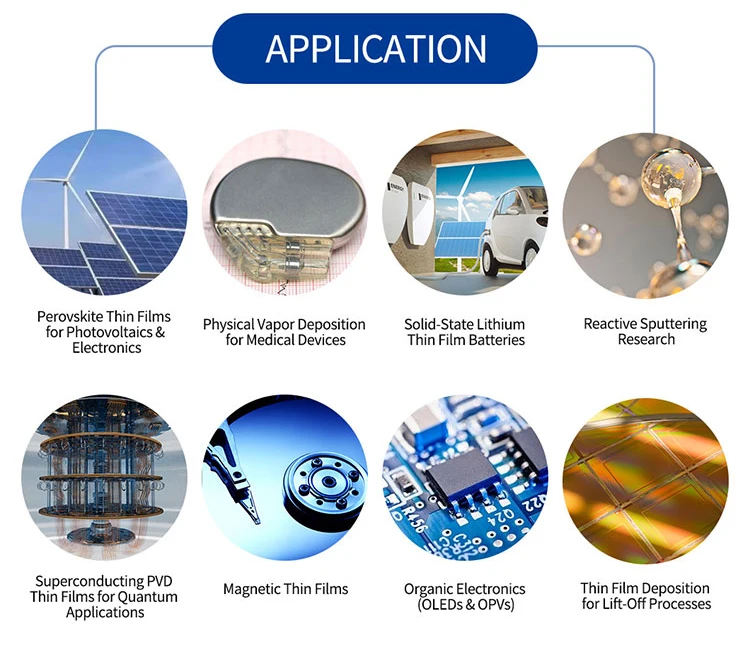

This system is ideal for research and development, battery and capacitor production, semiconductor coating, optical film creation, and protective coating fabrication for electronic devices.

12. What features enhance the accuracy of gas control in the system?

The system is equipped with high-precision mass flowmeters that ensure accurate gas control during the sputtering process.

13. Is there an integrated control system for the machine?

Yes, the system comes with an integrated industrial computer that allows for easy control and monitoring of the sputtering process.

14. What makes this system cost-effective?

The system features a triple target magnetron sputtering coater, which allows for versatile material deposition while minimizing costs associated with multiple systems.

15. What applications are suitable for this sputtering system?

Suitable applications include the production of thin films, electrode films for batteries, substrate coatings in the semiconductor industry, optical film creation, and protective coatings for electronics.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading