B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

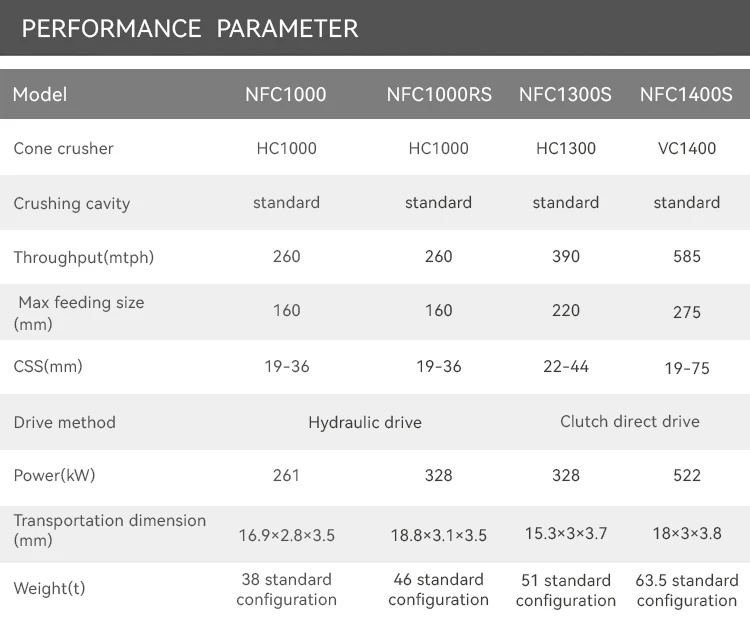

1. What is the throughput capacity of the High capacity stone crusher?

Capacity depends on model and feed size; typical high-capacity crushers handle from 100 to 2,000+ tons per hour. Exact throughput should be confirmed for the selected model and material properties.

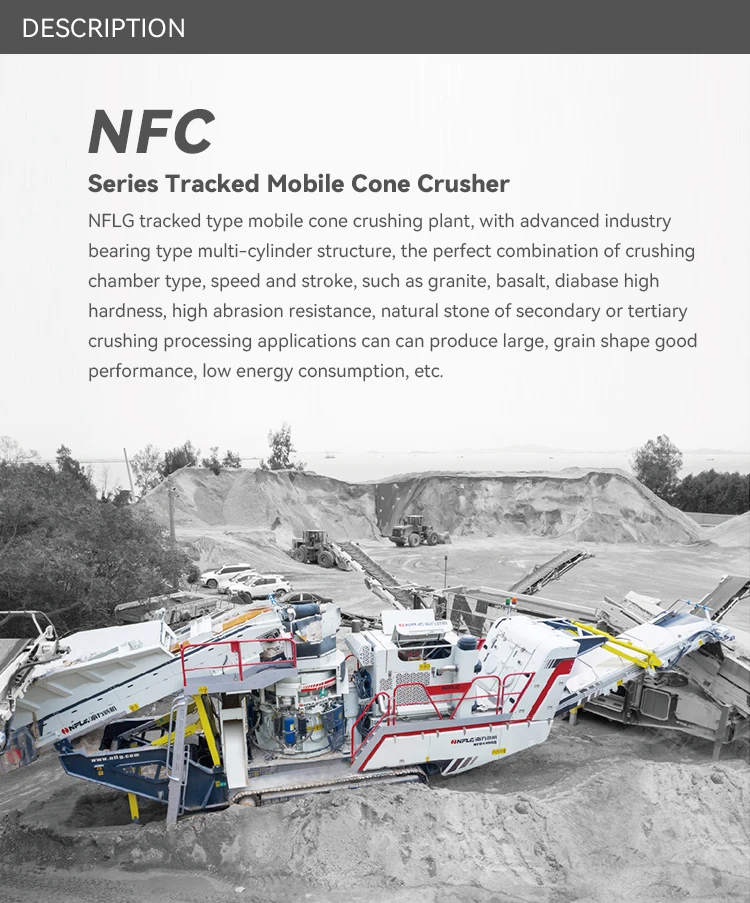

2. What types of stone and materials can this crusher process?

It can process a wide range of hard and medium-hard materials including granite, basalt, limestone, river stone, and recycled concrete. Some very abrasive or sticky materials may require specialized wear parts or pre-screening.

3. What is the maximum feed size the crusher can accept?

Maximum feed size varies by crusher model and configuration; common high-capacity machines accept feed sizes from 300 mm up to 1,200 mm. Check the specific model specification for exact limits.

4. What final product sizes and gradations can be produced?

Final product size is adjustable via crusher settings, screens, and secondary/tertiary crushing stages. Typical outputs range from coarse aggregate down to 0–5 mm fines, depending on configuration.

5. What power requirements does the machine have?

Power requirements depend on crusher type and capacity; large high-capacity units commonly require diesel engines or electric motors in the hundreds to thousands of kilowatts. Confirm power supply options (electric or diesel) for the chosen model.

6. Is the crusher available as a mobile or stationary unit?

High-capacity crushers are available in both stationary (plant) and mobile (tracked or wheeled) configurations. Choose stationary for fixed plants and mobile for flexible or multi-site operations.

7. What maintenance is required and how often?

Regular maintenance includes inspecting and replacing wear parts (jaw/concave/liners), checking bearings, lubrication, checking belt tensions and screens, and clearing blockages. Daily inspections and scheduled preventive maintenance (weekly/monthly) are recommended depending on usage.

8. What are the common wear parts and their expected life?

Common wear parts include jaws, mantles, concaves, blow bars, and liners. Wear life varies with material abrasiveness and operating hours; typical intervals range from hundreds to several thousand operating hours. Keep spare wear parts on hand for high-utilization sites.

9. What safety features are included?

Standard safety features include emergency stop systems, safety guards, lockout/tagout access points, overload protection, remote shutdown, and operator enclosures. Additional safety options can be added per site regulations.

10. How energy efficient is the crusher?

Energy efficiency depends on crusher design, drive system, and operational practices. Modern high-capacity crushers use optimized rotor designs, variable speed drives, and automated control systems to reduce energy consumption per ton processed.

11. Can the crusher be integrated into an automated plant control system?

Yes. Many models support PLC-based automation, remote monitoring, process control integration, and telematics for performance tracking, fault diagnostics, and preventive maintenance scheduling.

12. What installation and foundation requirements are needed?

Stationary crushers typically require reinforced concrete foundations sized per equipment weight and dynamic loads; mobile units need level, stable ground and optional anchoring. Installation details and foundation drawings are provided with the machine specifications.

13. What is the typical noise and dust level, and how are they managed?

Crushing operations generate significant noise and dust. Noise levels vary by model and load; mitigation includes acoustic enclosures and site layout. Dust suppression methods include water spray systems, dust extraction, and enclosed transfer points to meet regulatory limits.

14. Do you provide spare parts, service, and technical support?

Yes. Manufacturers or dealers typically offer OEM spare parts, service contracts, field service engineers, and remote technical support. Service availability depends on region—confirm local support options.

15. What warranty and after-sales options are available?

Warranties vary by supplier but commonly cover manufacturing defects for a specified period or operating hours. Extended warranties, service agreements, operator training, and commissioning support are often available as options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading