B21, China Town Mall, Midrand

Hand-push Pile Cutter Concrete Pile Cutter Cement Pile Cutter

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600817491984

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 14 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is this product and what is it used for?

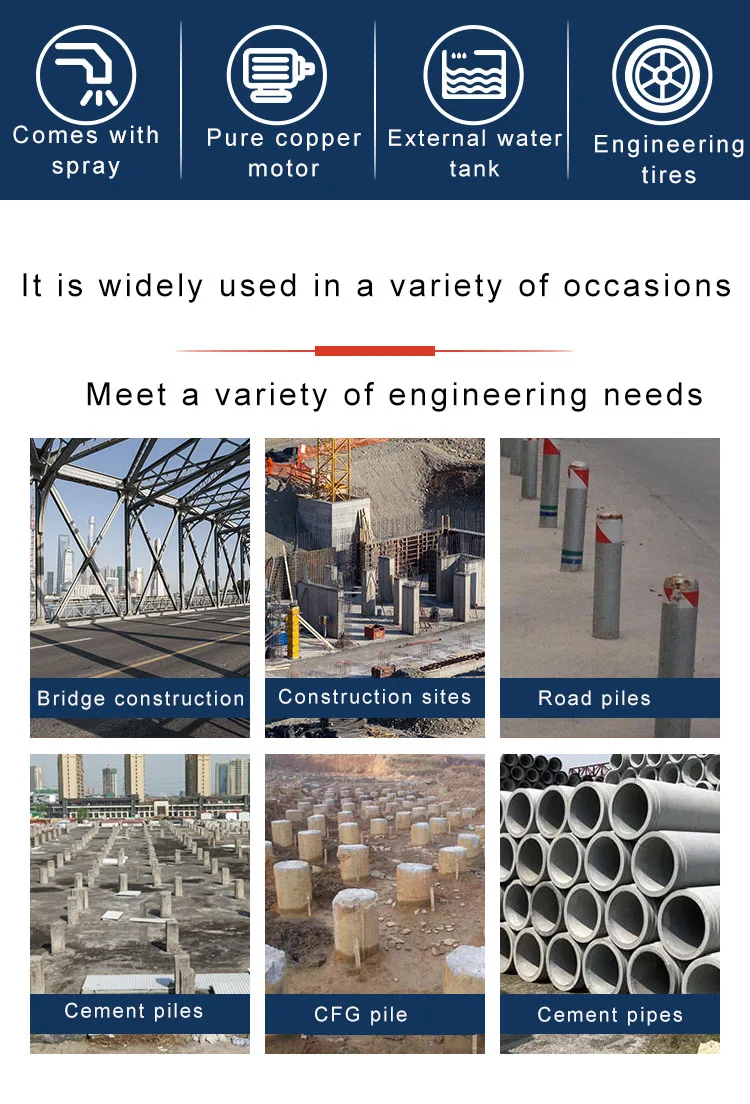

This is a hand-push concrete/cement pile cutter designed to cut concrete piles and similar precast concrete elements on site. It’s a mobile saw unit used to trim or shorten piles to the required length.

2. What are the key technical specifications?

Cutting speed: 2700–5400 mm/min; motor power: 7.5 kW (copper wire motor); spindle speed: 1900 r/min; compatible saw blade diameter: 300–600 mm; size: 100 × 80 × 80 cm; weight: 150 kg.

3. What type of motor does it use and what are the benefits?

It uses a pure copper-core 7.5 kW motor. Copper-core windings improve electrical conductivity, efficiency and heat dissipation, which increases work efficiency and durability.

4. How does the water/spray system help during cutting?

The thickened water tank and integrated spray system provide consistent water to the cutting zone for cooling and dust suppression, which reduces blade wear, stabilizes cutting and lowers dust exposure.

5. What blade sizes are supported and how do I select a blade?

The cutter accepts blades with diameters from 300 to 600 mm. Choose a blade rated for wet cutting of concrete/pile material and compatible with the spindle bore and RPM range (1900 r/min).

6. Is the blade fixed securely and how is vibration handled?

Yes — the saw blade mounting is designed for stable fixation and anti-shake performance. The machine also features an ergonomic, non-slip handle to reduce operator vibration and fatigue.

7. What safety features does the machine have?

Safety features include a stable blade fixation to reduce vibration, an ergonomic non-slip handle, a water spray system for dust control, and a robust frame with thickened steel plate to protect internal components. Always use PPE (eye, ear, respiratory protection) and follow local safety rules.

8. How portable is the cutter and how is it moved on site?

The unit weighs about 150 kg and has barbed anti-skid tires for on-site mobility. It is hand-pushable for short moves; for transport over longer distances use appropriate lifting/moving equipment.

9. What maintenance is required to keep the cutter operating well?

Regular maintenance includes keeping the water tank clean and filled, inspecting and replacing worn blades, checking and tightening blade mounting and bolts, cleaning filters/nozzles in the spray system, and periodic motor inspections/lubrication per supplier recommendations.

10. How often should I replace the saw blade?

Blade life depends on material hardness, cutting load and cooling. With the integrated water cooling and correct blade choice you’ll get extended life, but inspect the blade before each use and replace when cutting performance drops or the blade shows wear/damage.

11. What power supply and electrical connections are required?

The motor is rated at 7.5 kW. Exact voltage and phase (single/three-phase) are not specified here—confirm required voltage and connection type with the supplier or in the product manual before operation.

12. Can this cutter handle reinforced concrete piles (with rebar)?

It is designed for concrete piles; cutting through reinforced sections is possible with the right diamond blade rated for rebar and concrete. Expect increased blade wear and ensure appropriate blade type and slower feed if cutting through dense rebar.

13. Are spare parts and accessories available (blades, nozzles, belts)?

Spare parts availability varies by supplier. Common replaceable items include diamond saw blades, spray nozzles, drive belts and motor components. Check with your vendor for compatible parts and kits.

14. What warranties or after-sales support are provided?

Warranty and after-sales support depend on the manufacturer or seller. Ask the supplier for warranty terms, service options, and availability of local technical support before purchase.

15. How do I operate the cutter safely and efficiently?

Use proper PPE, secure the pile, select the correct blade, keep the water tank filled, set an appropriate feed rate (observe 2700–5400 mm/min range as a guide), maintain steady hand control using the ergonomic handle, and stop to inspect the blade or fittings if vibration/noise increases.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading