B21, China Town Mall, Midrand

Hand Pushed Concrete Floor Milling Machine for road construction(JHE-200)

- Section : Machinery

- Category : Construction Machinery

- SKU : 60661962597

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Hand Pushed Concrete Floor Milling Machine (JHE-200) used for?

It is designed for milling and removing surface layers of concrete and asphalt on small to medium sized areas for road repairs, surface profiling, removing coatings/adhesives, and leveling localized defects.

2. What does 'hand pushed' mean for this model?

Hand pushed means the operator walks behind and manually guides the machine during milling rather than riding on it or it being fully self-propelled. This makes it better suited to small jobs and confined spaces.

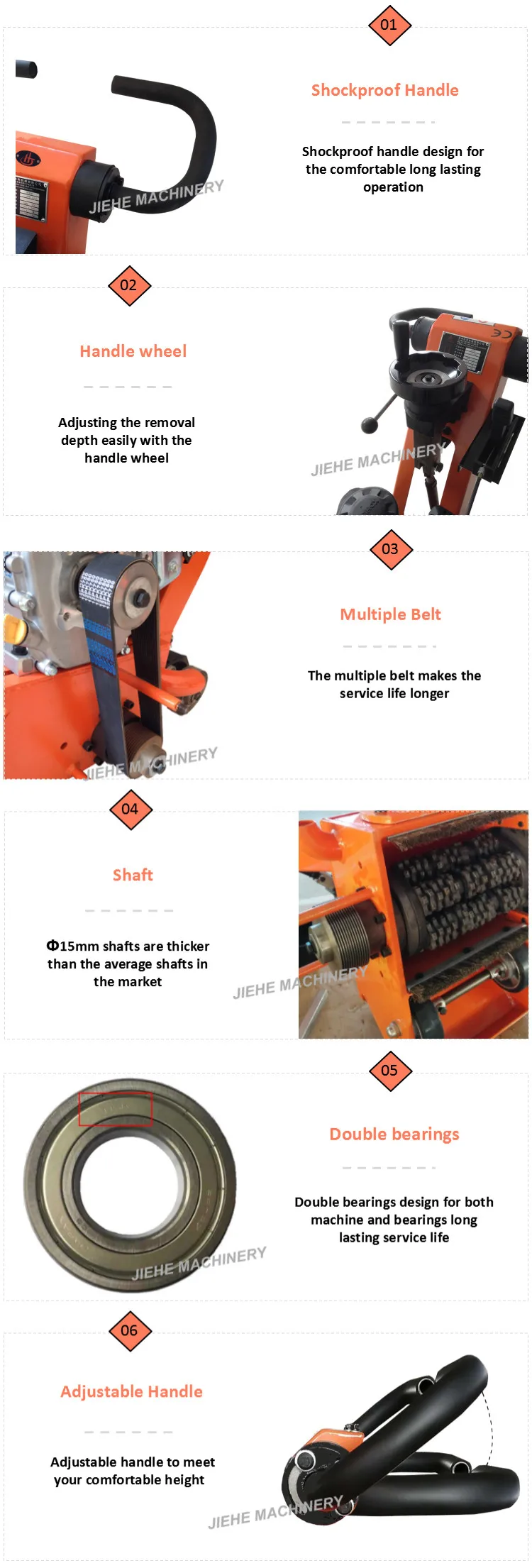

3. What are the key features of the JHE-200?

Key features include a low centre of gravity for stable, quiet operation, tripled drum bearings for durability, hardened cutter shafts for reliability, and a design optimized for quick and even milling on small to medium areas.

4. What milling width and depth can the JHE-200 achieve?

Exact cutting width and maximum depth depend on the machine configuration. The model designation (JHE-200) commonly indicates a compact working width, but you should consult the product specification sheet or supplier for the precise numbers for this unit.

5. What type of power source does the JHE-200 use?

Power options can vary by build and market; small floor milling machines are frequently offered with petrol, diesel or electric drives. Confirm the installed motor type and electrical requirements with your supplier.

6. Which cutters does the machine use and are replacement cutters available?

The machine uses hardened cutter shafts with replaceable milling tools (typically tungsten-carbide teeth or similar). Replacement cutters and teeth are standard service items and are normally available from the manufacturer or parts distributors.

7. How should I operate the JHE-200 for best results?

Perform a pre-check, set the desired milling depth, start the engine/motor, engage the drum and move the machine at a steady pace. Make multiple shallow passes rather than a single deep cut for an even finish and less wear on components.

8. What routine maintenance does the machine require?

Daily checks of cutters, drum bearings, belts/chains, and fasteners; cleaning debris from the drum area; regular lubrication of grease points; and scheduled inspection/replacement of wear parts per the operator manual.

9. What safety precautions should operators follow?

Wear PPE (safety boots, eye protection, hearing protection, dust mask/respirator), ensure good footing, keep bystanders clear, shut off and isolate power before servicing, and follow the operator manual for safe starting, stopping and maintenance procedures.

10. How is dust and noise managed when milling?

The JHE-200 is described as having quiet running characteristics, but milling still generates noise and dust. Use a local dust-extraction/vacuum system or water suppression where permitted, and ensure operators wear appropriate hearing and respiratory protection.

11. Can the JHE-200 mill both concrete and asphalt?

Yes. It is suitable for milling concrete and asphalt surfaces, including removing surface layers, coatings and localized defects. Always select cutters appropriate for the material being milled.

12. How portable is the machine and how should it be transported?

It is compact and hand-pushed on site but can still be heavy. Use proper lifting points and transport on a trailer or truck bed, securing it for transit. Check the manual for weight and securing instructions.

13. What productivity can I expect from this machine?

Productivity depends on material hardness, milling depth, cutter type, and operator technique. As a compact unit intended for small to medium jobs, it is optimized for local repairs and profiling rather than high-volume continuous milling. Ask the supplier for performance data or job-site trials.

14. Are spare parts and service available for the JHE-200?

Manufacturers typically provide spare parts (cutters, bearings, belts, etc.) and after-sales service for equipment like this. Confirm parts availability, lead times and service networks with the manufacturer or dealer before purchase.

15. How do I choose between the JHE-200 and a larger milling machine?

Choose based on the area size, required production rate, milling depth, transport constraints and job frequency. The JHE-200 is suited for small/medium jobs and tight spaces; for large continuous projects, a larger self-propelled cold planer will be more productive.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading