B21, China Town Mall, Midrand

Glossy Matt Eco Solvent Printing PVC Printable Adhesive Vinyl Sticker Roll Self Adhesive Vinyl

- Section : Consumer Electronics

- Category : Sublimation Printers

- SKU : 1600428926289

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 16 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What standard sizes and lengths are available?

Widths: 1.07 / 1.27 / 1.37 / 1.52 m (3.5ft / 4ft / 4.5ft / 5ft). Lengths: 50 / 70 / 100 m (164ft / 232ft / 328ft). OEM / custom sizes are acceptable on request.

2. What is the material and thickness of the vinyl?

PVC film: calendered monomeric A+ grade and polymeric options. Thickness: 80 or 100 µm (±5 µm).

3. What surface finishes do you offer?

Available finishes: Glossy, High Glossy and Matte (sometimes labeled as 'Glossy Matt' in product name).

4. Which adhesive types and colors are available?

Adhesive types: Permanent and Removable. Adhesive colors: Clear, Black and Grey.

5. What kind of liner does the roll have?

Silicon release paper liner, white color. Liner weight options: 100 / 120 / 140 ±5 gsm.

6. Which inks and printing methods are compatible?

Compatible with solvent and eco‑solvent inks. Recommended for digital printing and silkscreen. If you plan to use latex or UV inks, confirm compatibility with the supplier.

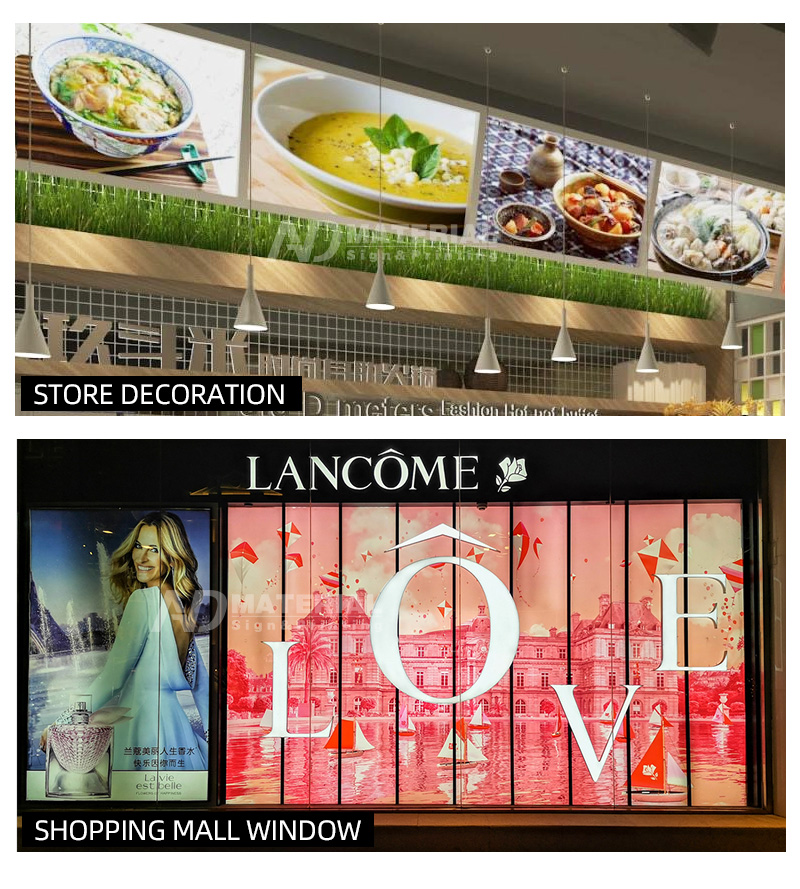

7. What are the recommended applications?

Intended for indoor and outdoor digital and silk‑screen printed graphics such as billboards, signage, vehicle and truck graphics, KT board, acrylic, airport and subway graphics, and similar applications.

8. Is this product suitable for vehicle wraps?

Yes, it's suitable for vehicle and truck graphics. Calendered monomeric vinyl is typically used for short to medium‑term vehicle graphics; polymeric calendered vinyl offers longer outdoor performance. For full long‑term vehicle wraps, consult the supplier about film choice and install method.

9. How should the vinyl be installed?

Clean and dry the substrate thoroughly, align the graphic, use a squeegee to apply pressure and remove air, and use heat (heat gun) for conforming around curves if needed. Recommended installation temperatures are moderate (approximately 15–25°C). Professional installation is recommended for vehicle and complex applications.

10. How is the vinyl removed and will it leave residue?

Removable adhesive products peel off more cleanly. Permanent adhesive may leave residue after long-term exposure—use heat to soften adhesive and peel slowly; residue can be removed with appropriate adhesive removers or isopropyl alcohol. Test on a small area first.

11. What outdoor durability can I expect?

Durability depends on film type, ink, lamination, and environmental conditions. Typical expected outdoor life for calendered monomeric vinyl is around 3–5 years and for polymeric calendered vinyl around 5–7 years under normal conditions. For precise fade/weathering data, request supplier technical data sheets or accelerated aging tests.

12. Can I print on clear as well as white vinyl?

Yes. White film provides an opaque printable base for full‑color graphics. Clear film is used for die‑cut stickers, window graphics or designs where transparency is desired—note that colors printed on clear film will be less opaque than on white.

13. Are custom sizes, rolls and private‑label (OEM) options available?

Yes. The product description states OEM sizes are acceptable—contact the supplier with required width, length and any custom finish or adhesive requests.

14. How should the rolls be stored and what is the shelf life?

Store in original packaging, upright or flat in a cool, dry place away from direct sunlight and extreme heat. Recommended storage conditions are around 20°C and moderate humidity. Typical shelf life is about 12 months; confirm exact shelf life with the supplier.

15. Do you provide technical data sheets, color profiles or warranties?

Technical data sheets (TDS), recommended ICC profiles, and warranty information are typically provided by the supplier or manufacturer. Ask your vendor for the TDS, print profiles and warranty terms before purchase to ensure the product meets your project requirements.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals