B21, China Town Mall, Midrand

Footwear Leather Shoe UV Ultraviolet Lighting Machine

- Section : Machinery

- Category : Shoe Making Machines

- SKU : 1600417726173

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

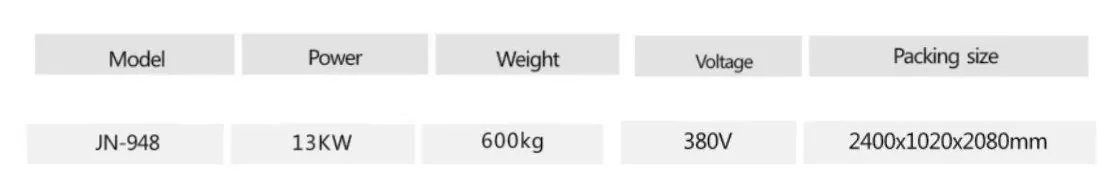

1. What is the model and main specifications of this machine?

Model JN-948. Power 13 kW, voltage 380 V (three-phase), net weight 600 kg, capacity up to 6,000 pairs in 8 hours (≈750 pairs/hour), packing size approximately 2400×1020×2080 mm.

2. What does the machine do and who is it for?

The machine applies UV lighting to footwear and leather components after primer application to increase adhesive capacity, speed drying, and improve bond strength. It is designed for shoe manufacturers and leather product factories.

3. How does the UV process improve adhesive performance?

After primer is applied, UV illumination activates or accelerates curing of adhesive components and primers, strengthening bonds between materials and improving overall footwear durability and quality.

4. What is the throughput or production capacity?

Rated capacity is 6,000 pairs in an 8-hour shift, which equals approximately 750 pairs per hour. Actual throughput may vary with part size, loading patterns and cycle settings.

5. What are the electrical and installation requirements?

Requires a 380 V three-phase power supply capable of supporting a 13 kW load. A dedicated circuit and qualified electrician are recommended. Verify local electrical codes and provide proper grounding.

6. What safety features are included?

Built-in safety alarms detect UV lamp malfunctions; when triggered, an alarm light flashes and the conveyor stops to prevent damage. Operators should still wear appropriate PPE (UV eye/skin protection) and follow safety procedures.

7. What personal protective equipment (PPE) and safety precautions are recommended?

Use UV-rated goggles or face shields and protective clothing when servicing lamps or if there is potential for direct UV exposure. Follow lockout/tagout procedures before maintenance and keep unauthorized personnel away during operation.

8. How is the machine cooled and how does it prevent EVA distortion?

The machine uses a special wind path design to maintain lower internal temperatures, reducing the risk of EVA or other thermoform distortion while still providing effective UV exposure.

9. What routine maintenance is required?

Regular tasks include cleaning lamps and reflectors, inspecting and cleaning fans and air paths, checking conveyor alignment and belts, replacing UV lamps per manufacturer life expectancy, and verifying alarms and electrical connections.

10. How often do UV lamps need to be replaced and are replacements available?

Lamp life depends on usage hours and lamp type. Replace according to the supplier's recommended service hours or when intensity drops. Contact the supplier or authorized dealer to source correct replacement lamps and parts.

11. What are the space and floor load considerations?

Net weight is 600 kg; ensure the installation floor can support this load plus dynamic forces. Allow clearance around the unit for maintenance (manufacturer recommended service space) and for ventilation/airflow.

12. Can the machine be adjusted for different shoe styles and sizes?

Yes — conveyor speed and exposure parameters can typically be adjusted to accommodate various part sizes and processing times. For specific configuration needs, consult the supplier for guidance or customization options.

13. What happens if the UV lamp malfunctions during a run?

The built-in alarm system will activate: the alarm light will flash and the conveyor will stop automatically to prevent incorrectly processed parts and potential damage. Inspect and replace lamps or resolve faults before restarting.

14. Are certifications, warranty and after-sales support available?

Certification and warranty details are not provided in the listing. Contact the supplier or dealer for information on product certifications (CE, ISO, etc.), warranty terms, installation support and after-sales service.

15. How can I get a quote, spare parts or arrange installation and training?

Contact the manufacturer or authorized distributor directly. They can provide quotes, shipping details, spare parts lists, installation services, operator training and recommended maintenance schedules.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading