B21, China Town Mall, Midrand

Food Snakcs Filling Automatic Multi-Function Packaging Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1601027989708

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

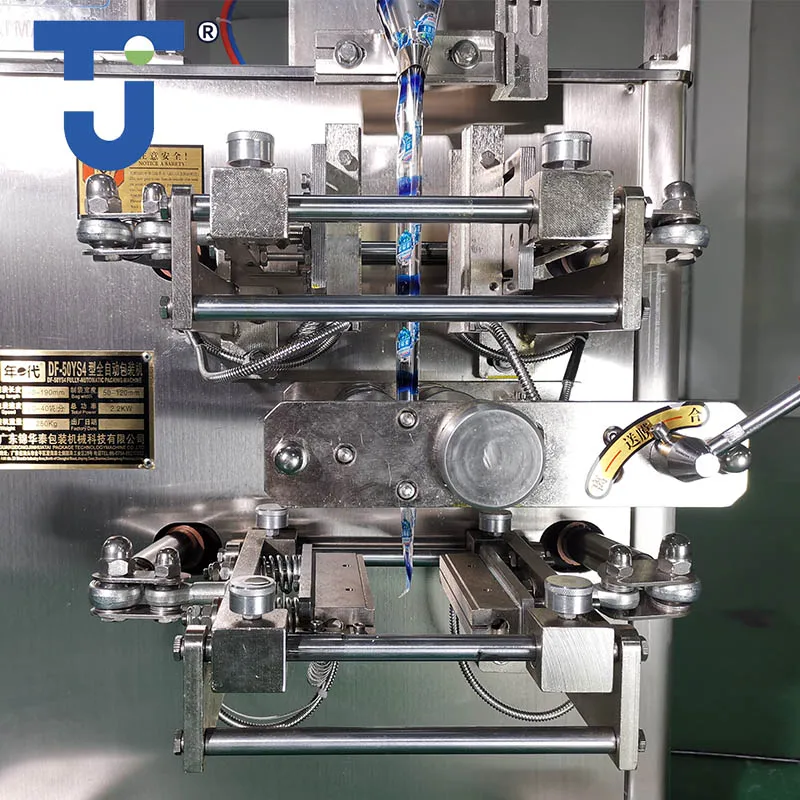

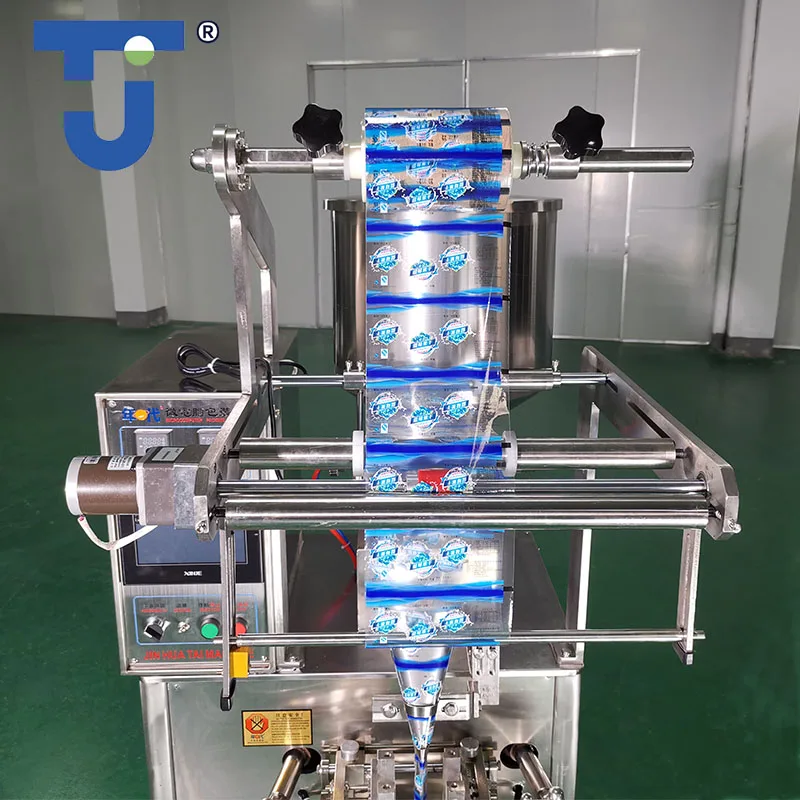

1. What is the Food Snakcs Filling Automatic Multi-Function Packaging Machine?

It is a mechanical liquid packaging machine (model DF-50SYP) designed for high-efficiency, four-side sealed sachet/pouch packing of liquids and semi-liquids such as sauces, jams, juices, yogurt, oils, shampoos and hand sanitizers.

2. Which industries and products is the machine suitable for?

Applications include food (sauces, condiments, jams, yogurt, oils), beverages (juices, drinks), medical/pharmaceutical liquids, and chemical/cleaning products.

3. What are the key technical specifications?

Model DF-50SYP; filling range 3–100 ml; bag size L: 50–135 mm, W: 40–140 mm; speed 30–50 bags/min; four-side sealing; piston filler; stainless steel (SUS304) body; total power 2.2 kW; voltage 220V 50/60Hz; machine weight ≈280 kg; dimensions 1000 × 800 × 1660 mm (L×W×H).

4. What types of bags and film materials does it accept?

It uses roll film to form sachets/pouches. Compatible film materials include composite films such as Metal (AL), Paper, OPP/CPP, PET/PE, PA, EVOH and other laminated roll films.

5. What sealing and cutting options are available?

The machine performs four-side sealing and offers cutting styles including zigzag (serrated) or flat scissor-type cuts, depending on your finished-package preference.

6. What filling system does the machine use and what viscosities can it handle?

A stainless-steel piston filler is used, suitable for a wide range of viscosities from thin liquids (drinks, oils) to thicker products (sauces, jams, yogurt). Heavily particulate or very chunky products should be tested to confirm performance.

7. How accurate and consistent is the filling?

The piston filling system and stepper-motor control provide high repeatability and precise bag length control. Actual fill accuracy depends on product viscosity and calibration—final accuracy is established during machine commissioning and testing.

8. How do I change bag size or adjust settings?

Bag length and other parameters are set via the touch-screen HMI. The stepper motor allows bag-length adjustments without stopping the machine. Film loading uses a clip-on film mechanism for quick changeovers; typical changeover time is short and depends on operator familiarity.

9. Is the machine easy to operate and maintain?

Yes. The touch-screen interface simplifies operation and speed regulation. The stainless-steel construction and sanitary piston filler make cleaning straightforward. Routine maintenance includes regular cleaning of filling components, inspection of seals, and scheduled lubrication.

10. What utilities and installation requirements are needed?

Standard electrical supply: 220V 50/60Hz, total electrical power 2.2 kW. The machine footprint and approximate weight should be considered when siting (1000 × 800 × 1660 mm; ~280 kg). Additional utilities (e.g., compressed air, drainage) depend on optional accessories and site setup—please confirm with the supplier.

11. What is the production capacity (speed)?

Typical packing speed is 30–50 bags per minute. Actual throughput depends on bag size, product viscosity, film type and operator setup.

12. Can the machine run continuously with minor film static or disturbances?

Yes. The clip-on film filling design allows the machine to continue operating even with minor static in the film, reducing stoppages for small film issues.

13. Are optional accessories, customization or integrations available?

Yes. Optional accessories and customizations (e.g., date coders, conveyors, special nozzles, gas-flush or downstream equipment) can usually be supplied or integrated. Contact the manufacturer/supplier to discuss specific requirements.

14. What about certifications, warranty and after-sales support?

Certifications, warranty terms and after-sales support options vary by supplier and region. Please contact us or your local representative to obtain details about CE/ISO compliance, warranty length, spare parts and service contracts.

15. How do I get a quote, request testing or order the machine?

Contact the supplier with your product details (viscosity, particulates, desired bag size, film type and required output). The supplier can provide a formal quote, arrange product tests on the machine and discuss lead time, shipping and installation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading