B21, China Town Mall, Midrand

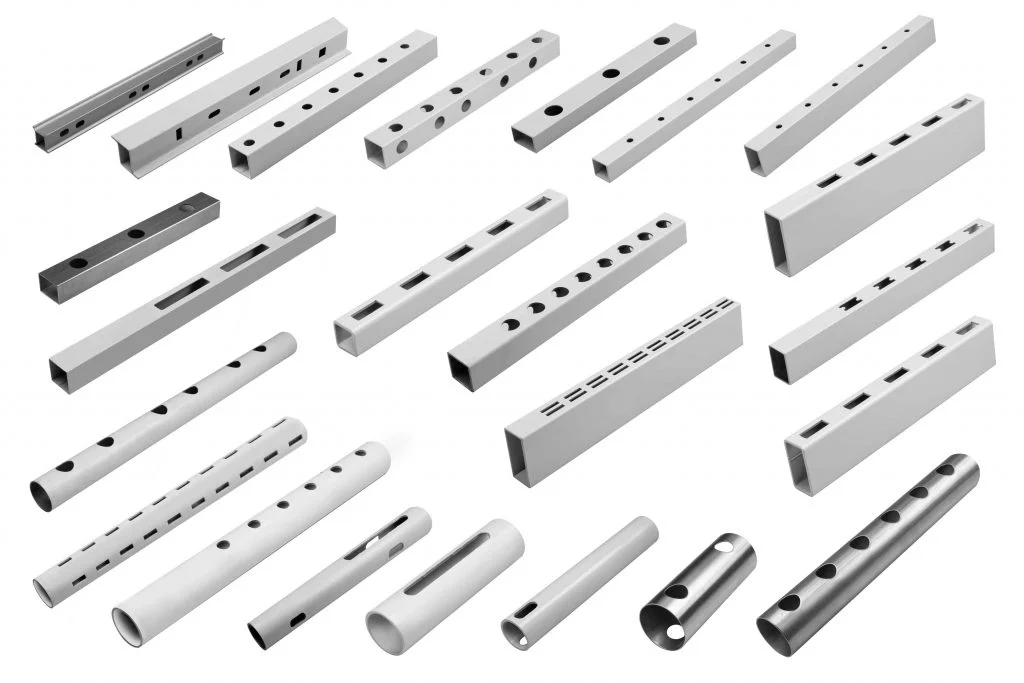

Electric Metal Hole Pipe Machinery Machine Tool Equipment: Punching Machines

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 1600666335624

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the model name and purpose of this machine?

The model is BR125CNC. It is an electric pipe/metal hole punching machine (CNC punching) used to punch holes in metal pipes and similar profiles.

2. What is the maximum material thickness the machine can punch?

Maximum material thickness is 4 mm.

3. What is the maximum process (pipe) length the machine can handle?

The machine supports a process length of up to 6000 mm (6 meters).

4. What are the motor and total power ratings?

The main motor power is 11 kW and the total installed power is 15 kW.

5. What is the feeding speed of the machine?

Feeding speed is up to 300 mm/s.

6. What hydraulic/working pressure does the machine use?

Working pressure is 31.5 MPa.

7. How much does the machine weigh and what are its dimensions?

Machine weight is approximately 2300 kg. Overall dimensions are 6800 mm x 1200 mm x 1500 mm.

8. How many cylinders does the machine have and what cooling is provided?

The machine has 2 cylinders and is equipped with a cooling fan.

9. What types of materials can this punching machine handle?

It is designed for metal pipes and thin metal profiles (for example mild steel or stainless steel) up to the specified 4 mm thickness. For specific alloys, diameters or wall configurations, consult the supplier for compatibility and tooling recommendations.

10. What kind of CNC/control accuracy can I expect?

The BR125CNC uses CNC control for precise and repeatable hole positioning. Actual accuracy depends on tooling, setup, and maintenance—contact the manufacturer for published tolerances or for application-specific accuracy data.

11. What are the electrical requirements for installation?

Total power is 15 kW; a suitable industrial three-phase power supply capable of delivering this load is typically required. Confirm voltage and wiring specifications with the supplier or installation manual prior to setup.

12. What installation, handling and maintenance considerations should I be aware of?

Allow space for the machine footprint (6800 x 1200 x 1500 mm) and safe access for operators. Lifting equipment (forklift/crane) is required for the 2300 kg weight. Follow the manufacturer’s manual for routine maintenance: keep tooling sharp, maintain hydraulic oil and filters, inspect seals and cylinders, and ensure cooling fan and electrical systems are functioning. Regular preventive maintenance preserves accuracy and extends service life.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading