B21, China Town Mall, Midrand

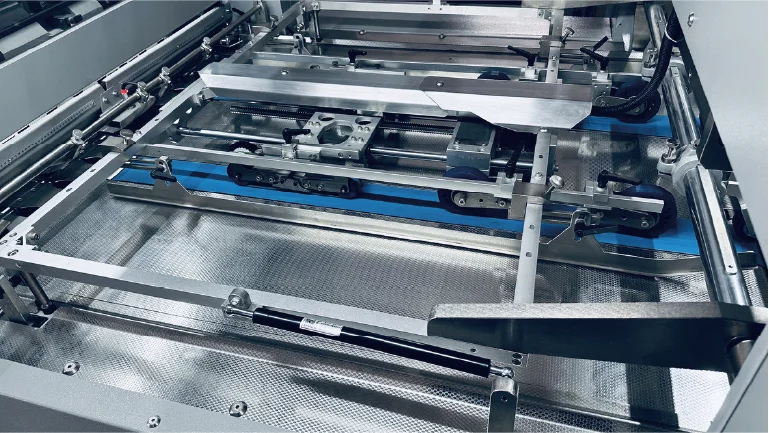

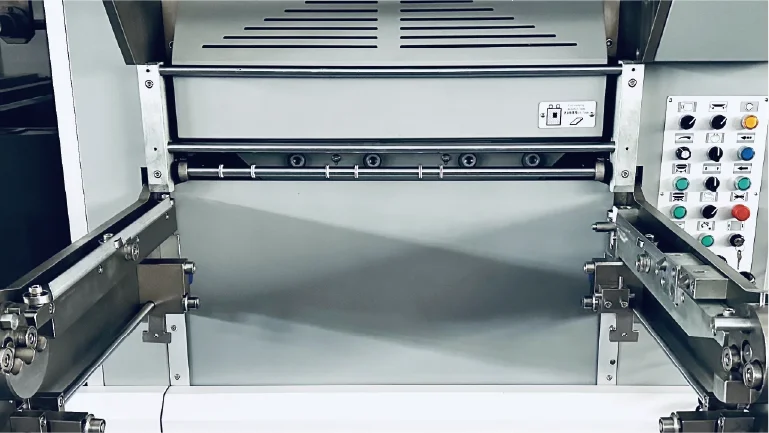

Easy Portable Mini Small Silkscreen Manual Cylindrical Round Textile Fabric Anti-Slip Socks Large Silk Screen Printing Machine

- Section : Consumer Electronics

- Category : Screen Printers

- SKU : 60680546553

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum sheet size that the Easy Portable Mini Small Silkscreen Machine can handle?

The maximum sheet size the machine can handle is 1060×760 mm.

2. What types of materials can be processed with this machine?

This machine can process a range of materials including cardboard (80-2000 g/㎡), and it can also handle corrugated materials up to 4 mm thick.

3. How fast can the die cutting and stamping be done?

The maximum die cutting speed is 7500 sheets per hour, and the maximum stamping speed is 7000 sheets per hour.

4. Does this machine have an automatic feeding function?

Yes, it features a non-stop feeder with anti-collision protection and electric adjustment for efficient paper feeding.

5. What is the max working pressure of the machine?

The maximum working pressure of the machine is 350 tons.

6. Can I adjust the temperature settings for foil stamping?

Yes, the machine has 12 individually heated zones that can be adjusted, with a maximum temperature of 200°C.

7. Is the machine easy to operate for beginners?

Yes, it features a 'SMART' one-button start function and a large touch capacitive screen for easy operation.

8. What safety features are included in the machine?

The machine includes a safety light curtain and anti-drop protection functions for enhanced safety during operation.

9. What is the power requirement for this printing machine?

The machine requires a power rating of 108 kW and a main motor power of 30 kW.

10. Does the machine have a lubrication system?

Yes, it has an automatic intermittent lubrication system to ensure smooth operation.

11. Can I use holographic foil with this machine?

Yes, the machine is equipped to handle holographic foil stamping as an optional feature.

12. What is the weight of the Easy Portable Mini Small Silkscreen Machine?

The machine weighs approximately 4300 kg.

13. Is there a warranty offered with the machine?

Warranty details can vary; please check with your sales consultant for specific warranty information.

14. Can I get support for maintenance and repairs?

Yes, the machine includes a remote module for fast and convenient maintenance support.

15. What is the delivery height capacity of the machine?

The maximum delivery pile height is 1100 mm, while without presetting, it can go up to 1400 mm.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading