B21, China Town Mall, Midrand

Dust removal equipment,air pollution control machine

- Section : Machinery

- Category : Filtration Equipment

- SKU : 1601050868626

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary function of the Bofilter Industrial Dust Collector?

The primary function is to remove airborne dust and particulates from industrial processes to improve air quality and create a safer, cleaner working environment.

2. What particle size can this dust collector filter?

It is capable of filtering particles down to 0.3 microns. Actual collection efficiency depends on the selected cartridge/media and operating conditions.

3. What are the unit dimensions and weight?

The unit measures 1550 mm (L) x 860 mm (W) x 2800 mm (H) and weighs approximately 300 kg.

4. Which power options are available?

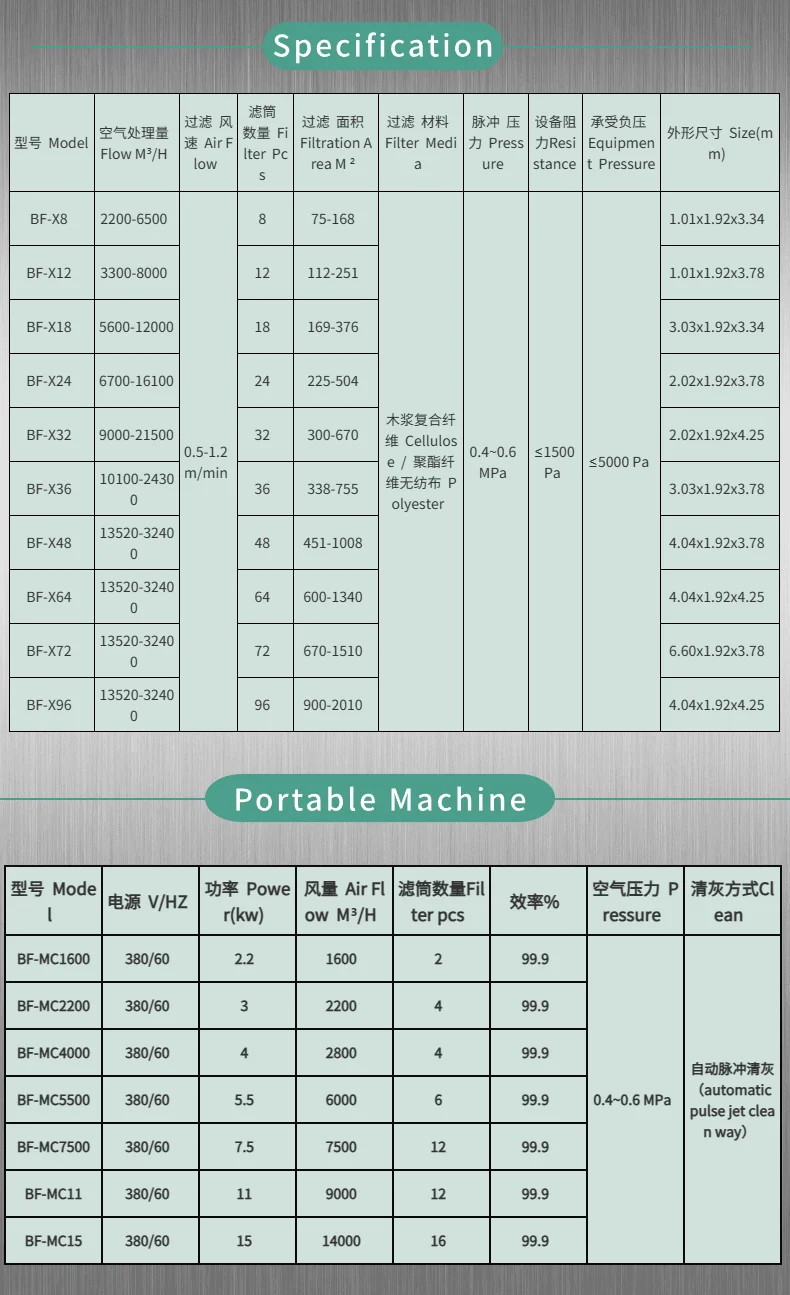

Multiple fan motor power options are offered: 2.2 kW, 3 kW, 4.5 kW, and 7.5 kW. Choose based on required airflow and dust load; consult the supplier for sizing.

5. What cleaning method does the system use?

It uses an automatic pulse jet (pulse inverse blow) cleaning system with air tank and valves to periodically clean the cartridge filters, enabling continuous operation.

6. What filter cartridge types and media are used?

The unit supports high-efficiency flame-retardant cartridge filters, including Toray PTFE-treated cartridges and synthetic F9 triangle cartridges. Cartridges can be mounted vertically or horizontally.

7. What materials is the dust collector constructed from?

Standard construction is carbon steel for durability. An SS304 (stainless steel) machine body and other stainless options are available—confirm material selection when ordering.

8. Which industries and applications is this collector suitable for?

Suitable for metalworking (grinding, smelting, welding fume), laser/plasma cutting, painting, woodworking, food/powder handling (flour, soybean), printing, construction, manufacturing, farms, restaurants and more.

9. How often do I need to replace filter cartridges and how is that determined?

Replacement frequency depends on dust load and particle type. The system includes a differential pressure table/instrumentation—replace cartridges when differential pressure reaches the recommended limit. Regular visual checks and scheduled inspections are advised.

10. Does the system require any additional utilities for operation?

It requires electrical power for the fan and control panel. The pulse-jet cleaning uses compressed air; the unit includes an air tank and valves but a shop compressed air supply or an onboard compressor may be required depending on configuration.

11. How is collected dust removed and handled?

Collected dust falls into a dust drawer/hopper with a removable volume for easy removal and disposal. For continuous handling, hoppers can be fitted with discharge valves or conveyors—discuss options with the supplier.

12. Can the unit color or configuration be customized?

Yes. Color customization and configuration adjustments are available based on customer requirements to integrate with your facility and process needs.

13. What maintenance tasks are required to keep the collector performing well?

Regular tasks include checking and replacing filter cartridges per differential pressure, inspecting pulse valves and air tank, emptying dust drawers, monitoring fan and motor, and verifying PLC/control settings. Keep records of service intervals.

14. What spare parts and consumables should I keep on hand?

Recommended spares include replacement filter cartridges, pulse valves, seals/gaskets, fan belts (if applicable), control fuses, and any commonly used sensors or PLC components.

15. Are there certifications, noise, or airflow specifications available?

Model-specific certifications (e.g., CE, ISO), noise (dB), and detailed airflow (m3/h / CFM) ratings are not listed in this summary. Contact Bofilter or your distributor for datasheets and certification documents for the exact model you plan to purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading