B21, China Town Mall, Midrand

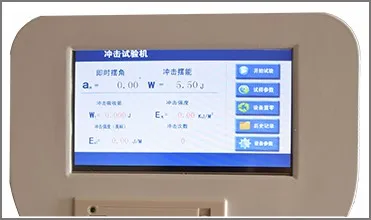

Digital Izod Impact Test Equipment for PE, PP, PVC, ABS, PS: Anytester HY4252D

- Section : Consumer Electronics

- Category : Test Instruments

- SKU : 60721899529

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the Anytester HY4252D Digital Izod Impact Tester evaluate?

It is designed to test impact resistance of common thermoplastics including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), acrylonitrile butadiene styrene (ABS), and polystyrene (PS).

2. Which standards does the HY4252D comply with?

The HY4252D is designed to meet ISO 20126 requirements for Izod impact testing. For other regional or industry standards (for example ASTM), verify test parameters and specimen preparation against those standards or consult the supplier.

3. What impact energies and models are available?

There are two model variants: HY4252DA offers selectable impact energies of 2.75 J and 5.5 J; HY4252DB offers 11 J and 22 J. Choose the model that fits the expected toughness range of your materials.

4. What are the key mechanical specifications (impact velocity, pendulum angle, center distance)?

Impact velocity is 3.5 m/s, the pendulum angle is 150°, and the impact center distance (pendulum swing radius) is 335 mm.

5. What are the machine dimensions, weight and power requirements?

Dimensions: 700 × 350 × 850 mm; Weight: 120 kg; Power supply: AC 220 V, 50 Hz.

6. What specimen type and dimensions does the HY4252D accept?

The tester is intended for standard Izod notched specimens per the applicable test standard (ISO 20126 or equivalent). Exact specimen dimensions and notch geometry should be prepared according to the standard you are using; consult the ISO document or the manufacturer for recommended fixture/ specimen details.

7. How do I choose the correct impact energy setting for my material?

Select an energy that bracket the expected toughness of your samples: use lower energies for brittle materials and higher energies for tougher specimens. If uncertain, run preliminary tests starting at the lower energy and increase as needed. Use a model (A or B) whose maximum energy exceeds the anticipated absorbed energy to avoid pendulum overrun.

8. Does the HY4252D provide digital readout or data export?

The HY4252D is a digital Izod impact tester and provides digital measurement readouts. For details on data export formats, connectivity (USB/RS232/Ethernet) or software integration, contact the supplier or consult the product manual.

9. What safety features and precautions should I follow when using this tester?

Always secure the specimen correctly, keep guards and safety interlocks in place, stand clear of the pendulum arc during operation, disconnect power before maintenance, and ensure only trained personnel operate the machine. Follow lab safety procedures and the operator manual.

10. How should the HY4252D be shipped and stored?

The unit is packed in an export-standard wooden case for safe delivery. Store the tester in a dry, vibration-free environment and keep the wooden case if long-term transport or storage is anticipated.

11. What routine maintenance and calibration are recommended?

Perform daily inspections for cleanliness and damage, keep pivot and moving parts lubricated as specified in the manual, and check anvils/striking edge condition. Arrange periodic calibration and verification according to your quality system—typically annual calibration by qualified service or sooner if accuracy is critical or after heavy use.

12. What spare parts or accessories are commonly available for this model?

Common accessories include additional pendulums (different energy capacities), anvils/fixtures for specimen clamping, notching tools, replacement striking edges, and calibration weights or certificates. Contact Anytester or an authorized distributor for specific parts and compatibility.

13. Which industries and applications commonly use the HY4252D?

Typical applications include quality control, R&D and incoming inspection in plastics manufacturing, automotive components, packaging materials, consumer goods and any industry where material toughness and impact resistance are important.

14. Who do I contact for warranty, service or technical support?

Warranty, service plans and technical support are provided by the manufacturer or authorized distributors. Contact Anytester or your regional supplier for warranty terms, service agreements, calibration services and spare parts availability.

15. Can the HY4252D test different specimen thicknesses and notched configurations?

Yes — the tester accommodates standard Izod notched specimens per the test standard, but the exact allowable thicknesses and notch configurations depend on the standard and fixtures used. Confirm permitted specimen geometries with the operator manual or the manufacturer before testing.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading