B21, China Town Mall, Midrand

Cow Dung Manure Dewatering Machine

- Section : Machinery

- Category : Agriculture Machinery

- SKU : 1600499395215

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

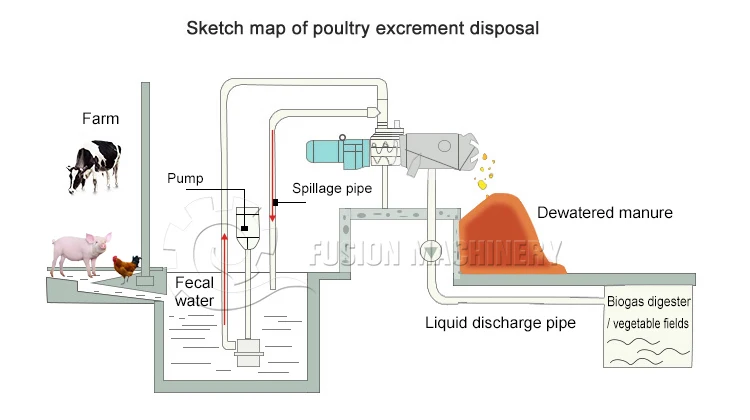

1. What is the Cow Dung Manure Dewatering Machine and what does it do?

It is a screw-type solid–liquid separator designed to separate solid and liquid fractions from animal manure (cow, pig, poultry, horse). It reduces volume, produces a transportable dry solid for fertilizer and a liquid fraction suitable for dilution and irrigation.

2. What is the processing capacity of the machine?

Typical capacity is 15–20 m³/h (depends on model and manure consistency). Actual throughput varies with feed concentration, pump rate and particle size.

3. What power supply and motor size does it require?

Standard specification uses a 4 kW motor and is designed for a 380 V three-phase supply (confirm voltage for your region or model).

4. What are the machine dimensions and weight?

Overall dimensions are approximately 2200 × 610 × 1350 mm and the machine weight is around 350 kg (model-dependent).

5. Which types of manure can this machine process?

It is suitable for cow, pig, poultry and horse manure, and generally works with other livestock slurries having similar particle sizes.

6. What are the inlet, screen and drain specifications?

Inlet diameter is 76 mm, standard screen diameter is 200 mm, and the liquid drain diameter is 110 mm (model-specific variations may apply).

7. What materials are used in construction?

Typical construction uses carbon steel combined with 304 stainless steel for the screen and wetted parts; some models use ductile iron plus 304 SS components for durability and corrosion resistance.

8. How does the screw dewatering/separator work?

A pump feeds slurry into the separator. The rotating extrusion screw pushes material toward a progressively narrowing end while a stainless steel screen allows expelled liquid to pass out via the drain. Solids are compacted and discharged continuously.

9. Do I need to add flocculants or chemicals?

No flocculants are required for normal operation; the screw extrusion and screening provide mechanical separation without added chemicals.

10. What is the quality of the separated solid and liquid outputs?

Solids are substantially drier, largely odor-reduced and suitable for storage or use as farmland fertilizer without producing leachate. The liquid fraction is wetter (contains a high share of water) with lower nutrient concentration and can be diluted for irrigation or fertiliser use.

11. What moisture content can I expect in the separated solids?

Moisture content varies with feedstock and operating conditions; solids are significantly drier than raw slurry and are easier to transport and store. For precise moisture targets, tests on your material and adjustment of feed rate/pressure are recommended.

12. What site and installation requirements are needed?

Provide a level, solid foundation and anchor bolts for mounting. Connect to a compatible slurry pump and a 3-phase power supply. Ensure appropriate drainage for the liquid outlet and allow space for maintenance and material handling equipment (forklift or crane for positioning).

13. What routine maintenance is required?

Regularly clean the screen and inlet, inspect and replace worn screens or screw flights, lubricate bearings as specified, check motor and electrical connections, and inspect seals and bearings for wear. Follow the manufacturer's maintenance schedule.

14. What safety precautions should operators follow?

Always isolate power before maintenance, never reach into the inlet or screw while running, provide guarding around moving parts, use PPE (gloves, eye protection, boots), and ensure only trained personnel operate the machine.

15. Are spare parts, service and warranty available?

Common spare parts include screens, screw augers, bearings and electrical components. Warranty and after-sales service terms vary by supplier—contact your vendor for specific warranty coverage, spare-parts availability and local service options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading