B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 02 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Construction Hoist by KOOD and what are its main uses?

The Construction Hoist by KOOD is a manual hand-chain hoist designed for lifting and positioning heavy loads. It’s suitable for construction sites, factories, warehouses, garment shops, hotels, food plants and other commercial or residential lifting tasks where a reliable, non-electric hoist is required.

2. What power source does the hoist use?

This hoist is manually operated via a hand chain — no electricity or external power source is required.

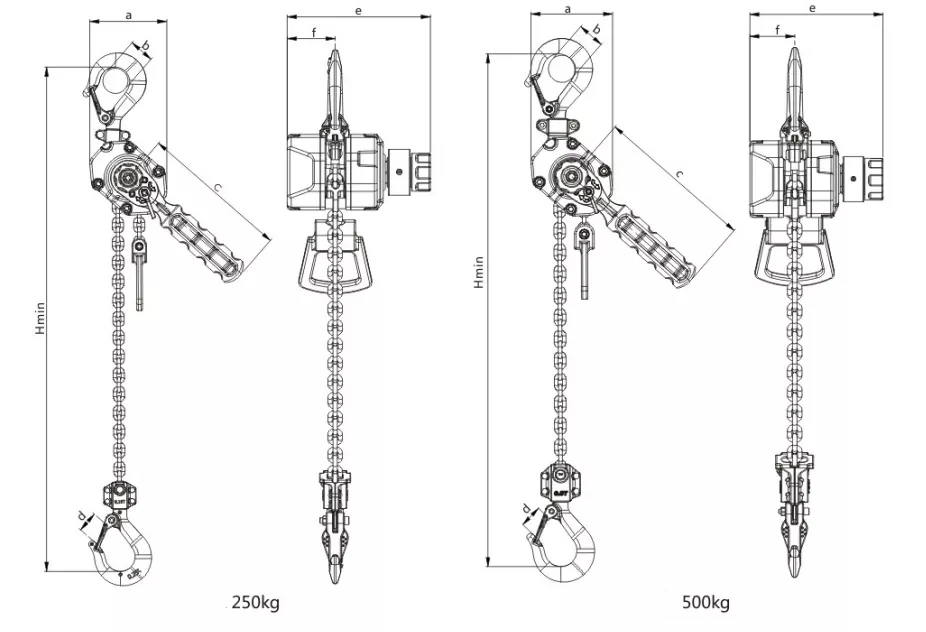

3. What load capacities are available?

KOOD’s Construction Hoist is offered in multiple capacities, commonly including 0.75, 1, 1.5, 2, 3 and 6 ton models. Choose the model rated for your maximum intended load plus a safety margin.

4. What are the available chain sizes and chain type?

Load chain diameters are available in 6 mm, 8 mm and 10 mm options. The hoist uses heavy-duty G80 manganese chain (treated for corrosion resistance) for smooth, durable operation.

5. What materials and safety features does the hoist have?

Key components such as hooks are made from forged alloy steel for toughness and corrosion resistance. The unit includes safety latches (capable of 360° rotation) and each hoist is proof loaded to 1.25 times its working load limit for safety and reliability.

6. What is the standard lifting height?

The standard lifting height supplied with these models is 1.5 meters. Custom lifting heights may be available — check with your KOOD supplier for options.

7. How do I choose the correct model for my application?

Select a model with a working load limit (WLL) above your maximum lifted weight, consider the required lift height, and choose the appropriate chain diameter for load and durability. If in doubt, consult KOOD or your equipment safety officer to factor in load type, frequency and safety margins.

8. Is the hoist portable and easy to install?

Yes — the hoist features a compact, one-piece design that is easy to transport and mount. It can be used with fixed suspension points or compatible trolleys (if required and rated) for traversing loads.

9. What routine maintenance is required?

Regular maintenance includes pre-use inspections, keeping the chain clean and lightly lubricated, checking hooks and latches for deformation or wear, ensuring the brake and load chain run smoothly, and replacing any damaged parts immediately. Follow the maintenance schedule recommended in the product manual.

10. How often should the hoist be inspected and tested?

Perform visual checks before each use. Conduct periodic detailed inspections (daily/weekly/monthly intervals depending on usage) and an annual thorough inspection by a competent person. Load-testing should follow local regulations and manufacturer recommendations; KOOD proof-tests each unit at 1.25×WLL before shipment.

11. Can this hoist be used in harsh or corrosive environments?

The hoist uses galvanized or treated chains and alloy steel components for improved corrosion resistance, but prolonged exposure to highly corrosive environments will accelerate wear. For severe environments consider additional protective coatings or more frequent inspections and maintenance.

12. What safety precautions should operators follow?

Never exceed the rated capacity, avoid side-pulling or shock loading, ensure loads are balanced and secured, keep hands and clothing clear of moving parts, and only allow trained personnel to operate the hoist. Follow the safety guidelines in the user manual and applicable workplace regulations.

13. What spare parts and accessories are available?

Common spare parts include replacement load chains (G80), hooks, latches, gearing components and brake parts. Accessories can include suspension hooks, trolleys and extended/optional chain lengths. Contact KOOD or an authorized distributor for genuine parts and compatibility.

14. Who should I contact for service, parts or warranty support?

Contact your KOOD dealer or authorized service center for parts, maintenance, and warranty support. Keep your model and serial number handy when requesting assistance to ensure accurate service and replacement parts.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals