B21, China Town Mall, Midrand

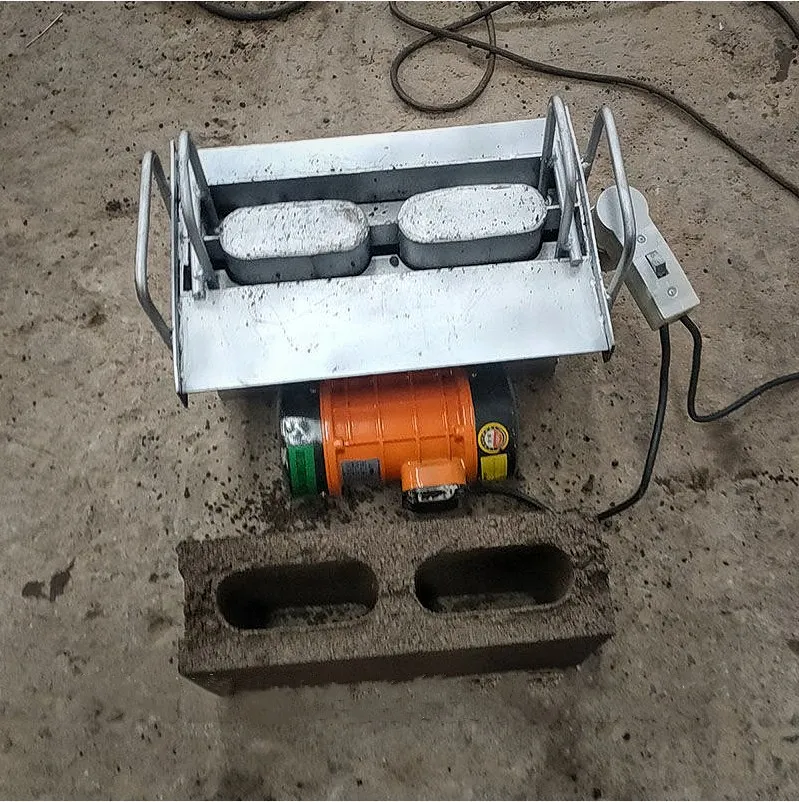

Cement hollow brick machine

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600493041598

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Cement hollow brick machine model and main purpose?

The model is QT10-2. It's a small-scale manual block-making machine for producing hollow blocks, porous blocks, solid concrete bricks and interlocking pavers using materials such as cement, concrete and fly ash.

2. What are the machine's main specifications (power, weight, size and voltage)?

Power: 550 W. Machine oversize (approx.): 420 × 380 × 280 mm. Weight: about 30 kg. Voltage options listed: 380V / 280V. Confirm actual voltage configuration with the supplier before ordering.

3. What production capacity can I expect?

Capacity depends on block size, mold type, mix and operator speed. Typical output per 8-hour shift (as given): 390×190×190 mm hollow block — 480–520 pcs; 390×150×190 mm hollow block — 480–520 pcs; 400×200×200 mm hollow block — 480–520 pcs; 240×115×43 mm solid block — 1,920–2,150 pcs.

4. What raw materials can the machine use?

Common materials include cement, sand, stone aggregates, and waste materials like fly ash. Exact mix ratios and admixtures depend on desired block strength and local materials — follow proven local recipes or supplier guidance.

5. How many operators are needed and how complex is operation?

The machine is designed for one-person operation and is described as simple to operate. Typical workflow: prepare mix, fill molds, compact/demold and stack for curing.

6. Can I produce different block sizes and types with this machine?

Yes. The QT10-2 can make hollow, porous and solid blocks. Different molds or mold inserts are used to produce different shapes and sizes; check with the supplier about available mold options or custom molds.

7. What are the recommended curing times for produced blocks?

Common practice: demold when blocks reach handling strength (often 24 hours depending on mix and conditions), then wet-cure for 7–14 days. Full design strength is typically assessed at 28 days. Adjust curing based on local climate and mix.

8. What maintenance does the machine require?

Regular maintenance includes daily cleaning of molds and contact surfaces, greasing/lubricating moving parts weekly, checking and tightening bolts periodically, and inspecting the vibration/motor assembly. Replace worn molds or parts as needed.

9. What are common wear parts and are spares available?

Common wear parts: molds, vibration motor components, seals, bearings and fasteners. Suppliers typically offer spare molds and replacement parts — confirm availability and lead times before purchase.

10. Is the machine portable and how is it shipped?

At about 30 kg and compact dimensions, the machine is easily transportable by small vehicle. Shipping/packing methods vary by supplier — contact the seller for packaging details, shipping cost and lead time.

11. What safety precautions should operators follow?

Use appropriate PPE (gloves, safety boots, eye protection), ensure electrical supply is properly grounded, keep hands clear of moving parts, turn off and isolate power before maintenance, and follow local electrical safety rules.

12. Can the machine be customized or scaled up?

Customization (different molds, special block shapes, or electrical configurations) is often possible. For larger production capacity, consider semi-automatic or fully automatic block-making equipment. Discuss needs with the supplier for options and pricing.

13. Is installation and training provided?

The machine is described as simple to operate and suitable for one-person use. Many suppliers provide operation manuals and can offer installation guidance or basic training — confirm training availability and costs with the seller.

14. What about warranty and after-sales support?

Warranty terms and after-sales support vary by manufacturer and dealer. Ask the supplier for warranty duration, scope, spare parts support and service contacts before purchase.

15. How do I choose the right mix and ensure consistent block quality?

Start with proven local mix formulas for the block type (cement:aggregate ratios, water content, and any fly ash/additives). Keep materials consistent, control moisture content, use proper compaction, and follow recommended curing. If unsure, request technical support or trial batches from the supplier.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals