B21, China Town Mall, Midrand

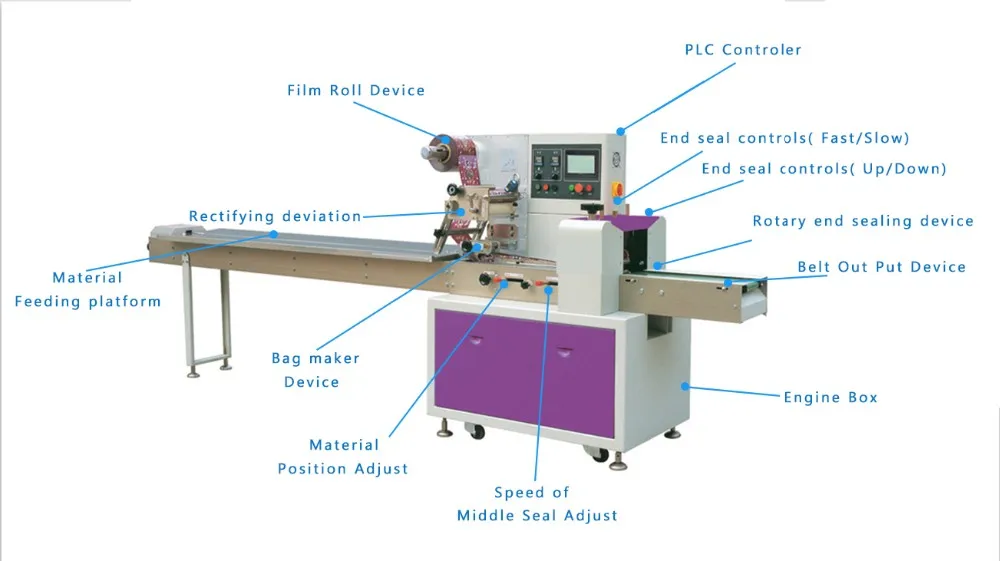

Bakery Food Biscuit Bread Cupcake Cookie Horizontal Automatic Packing Wrapping Machine

- Section : Machinery

- Category : Wrapping Machines

- SKU : 1600889349796

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of products can the TCZB-250B/D Flow Packing Machine package?

The TCZB-250B/D Flow Packing Machine is designed to package a variety of products, including biscuits, bread, soft candies, industrial parts, and more.

2. What is the maximum packaging speed of this machine?

The TCZB-250B/D can achieve a packaging speed of up to 230 bags per minute, ensuring high efficiency.

3. How does the PLC control system work?

The machine features an imported PLC control system with a color touch screen, allowing for easy and intuitive operation of the packaging process.

4. What materials can be used for packaging film?

This machine is compatible with various laminate plastic films, including OPP/CPP, OPP/CE, MST, and PE.

5. What bag shapes can the machine produce?

The TCZB-250B/D can create multiple bag shapes such as pillow bags, pocket bags, hole bags, and joint bags.

6. Is the film transport system accurate?

Yes, the machine uses an imported film transport system along with a color standard sensor for precise film positioning.

7. How does the external film mechanism work?

The external film mechanism simplifies and speeds up the installation of packaging film, making it easier for operators.

8. What is the maximum film roll diameter supported by the machine?

The TCZB-250B/D supports a maximum film roll diameter of 320mm.

9. Can the machine handle irregularly shaped products?

Yes, the machine is designed to pack both regular and irregular objects, such as soft candies, towels, and fresh fruits.

10. What safety features does the machine have?

The TCZB-250B/D is equipped with multiple automatic alarm protection functions to minimize potential damage during operation.

11. How is the seal cutting accuracy ensured?

The machine utilizes a color mark sensor for accurate seal cutting and positioning, ensuring even and symmetrical bag cutting.

12. What power supply is required for the machine?

The TCZB-250B/D requires a power supply of 220V, 50/60Hz, with a power consumption of 2.4KW.

13. Is there a user-friendly interface for operation?

Yes, the machine features a large, easy-to-use touch screen that provides clear controls for simple operation.

14. What optional devices are available for this machine?

Optional devices include a perforated knife holder, gusset bag device, continue link bag, nitrogen making machine, bag former, and finished conveyor.

15. How does the servo motor enhance performance?

The servo motor controls the film for high precision positioning and accurate sizing, improving the overall efficiency of the packaging process.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading