B21, China Town Mall, Midrand

Automatic Vertical L Type Sealing and Shrink Wrapping Machine

- Section : Machinery

- Category : Wrapping Machines

- SKU : 60661568167

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Automatic Vertical L Type Sealing and Shrink Wrapping Machine used for?

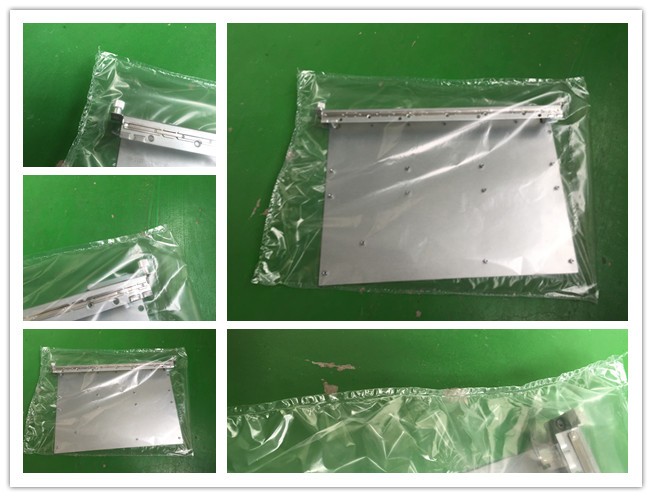

It's a combined vertical L-bar sealer and shrink tunnel used to seal and heat-shrink-wrap items such as photo frames, picture frames, aluminum/wood products, medical devices, electrical appliances, food and hardware/plastic products using PE or POF film, providing a cost-saving alternative to traditional carton packaging.

2. What are the maximum package and sealing sizes?

Maximum combined packing size (L+H) ≤ 500 mm, (W + 2H) ≤ 430 mm, maximum product height H ≤ 200 mm. Maximum sealing area: 550 × 450 mm. Tunnel internal size: 1500 × 450 × 220 mm.

3. Which films are compatible with this machine?

Designed for PE and POF heat-shrink films. Maximum film width (W) ≤ 550 mm, roll diameter (D) ≤ 250 mm, and maximum roll weight (G) ≤ 35 kg.

4. What are the electrical and air requirements?

Sealer power supply: 220V / 380V, 1/3PH, 50/60Hz, working power 1.8 kW. Shrink tunnel: AC 380/220V 3PH, 50/60Hz, power 12 kW. Compressed air: 6 kg/cm² (approx. 85 psi).

5. What is the production speed?

Packaging speed typically ranges from 15 to 30 pieces per minute, depending on product size, operator setup and film characteristics.

6. What sealing method does the machine use and what are its advantages?

It uses an L-type full closed vertical L-bar seal with an aluminum sealing knife coated in DuPont Teflon. This reduces sticking and high-temperature damage, prevents cracking and smoking, yields even seals, and avoids creased or messy sealing lines.

7. What automation features does the machine include?

Features include automatic feeding with sensor/time-relay controlled length, automatic film take-up by a reduction motor, built-in PID temperature control for precise seal temperature, PLC control with a 7-inch WEINVIEW touchscreen, and switchable auto/manual modes. It supports unmanned inline operation.

8. How does the machine ensure operator safety?

The sealing blade has an automatic protection function to prevent accidental cutting. Standard electrical and safety interlocks are used; operators should always power off and isolate the machine before performing maintenance or blade replacement.

9. What routine maintenance is required?

Regularly clean the Teflon-coated sealing knife and conveyor, check and tighten electrical and pneumatic connections, replace worn sealing wire or Teflon strip as needed, lubricate moving parts per the manual, and verify temperature PID and PLC settings. Keep spare consumables (sealing wire, Teflon tape, fuses).

10. What troubleshooting steps help with poor seals or film wrinkles?

Verify correct PID temperature, check sealing knife condition and Teflon coating, confirm proper film tension and alignment, ensure sensor and time-relay settings match product length, and confirm conveyor and shrink tunnel temperature/speed are set for the film type.

11. What are the machine dimensions and installation space requirements?

Sealer overall dimensions approximately 1800 × 1200 × 1400 mm (L×W×H); packaged size 1850 × 1300 × 1550 mm. Shrink tunnel machine size 1910 × 720 × 1320 mm. Allow additional clearance for loading, maintenance and ventilation when planning installation.

12. Can the machine be integrated into an existing production line?

Yes. The machine is designed for inline operation and can be integrated with upstream/downstream conveyors and production equipment. PLC control and standard interfaces simplify synchronization for unmanned operation.

13. What are the shrink tunnel controls and performance?

The tunnel has adjustable conveyor speed (1–15 m/min) and temperature control suitable for PE/POF films. Conveyor load capacity is up to 30 kg. Use proper tunnel temperature and speed settings for the chosen film and product to achieve uniform shrink.

14. Do you provide installation, training or spare parts?

Most suppliers offer installation support, operator training and spare parts packages (consumables like sealing wire, Teflon tape, fuses). Confirm with the vendor for warranty details, lead times and availability of local service and parts.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading