B21, China Town Mall, Midrand

Automatic Powder Coffee Stick Pack Packing Machine 4 Line Food Powder sachet packaging machines

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1601002718159

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the machine model and how many lanes are available?

This is model GH560BF. It supports multi-lane configurations from 3 up to 10 lanes.

2. Which filling/dosing methods does the machine use?

There are three dosing options: long auger, short auger, and short auger with cup. Choose based on powder type and required fill range.

3. What is the production speed / capacity?

Maximum is 40 cycles per minute. Total sachets per minute = cycles × number of lanes (for example, 4 lanes × 40 cycles = 160 stick packs/min). Actual throughput depends on sachet size, powder characteristics and selected auger.

4. What sachet sizes can it produce?

Supported sachet length (L) is 50–180 mm and width (W) is 20–90 mm.

5. What film width and thickness does the machine accept?

Maximum film (roll) width up to 560 mm. Recommended film thickness range is 0.07–0.10 mm. Use heat-sealable packaging laminate films compatible with stick packs.

6. What sealing and cutting styles are available?

Sealing: back sealing suitable for stick bags. Cutting options: straight cutting, zig-zag (serrated), round cutting and die-cut.

7. What are the air and electrical requirements?

Compressed air: 0.8 MPa (approx.) at 0.8 m³/min. Electrical power: 5.5 kW. Verify required voltage and phase with the supplier to match local supply.

8. What are the machine dimensions and weight?

Machine dimensions: 1685 × 1300 × 2005 mm (L×W×H). Net weight approximately 550 kg. Allow extra space for operator access, film loading and peripheral equipment.

9. Is the machine suitable for food-grade applications and what materials contact the product?

The machine is designed for food powder packaging (e.g., coffee stick packs). Product-contact parts are typically made from food-grade materials—commonly stainless steel—but confirm exact materials and any required certifications with the manufacturer.

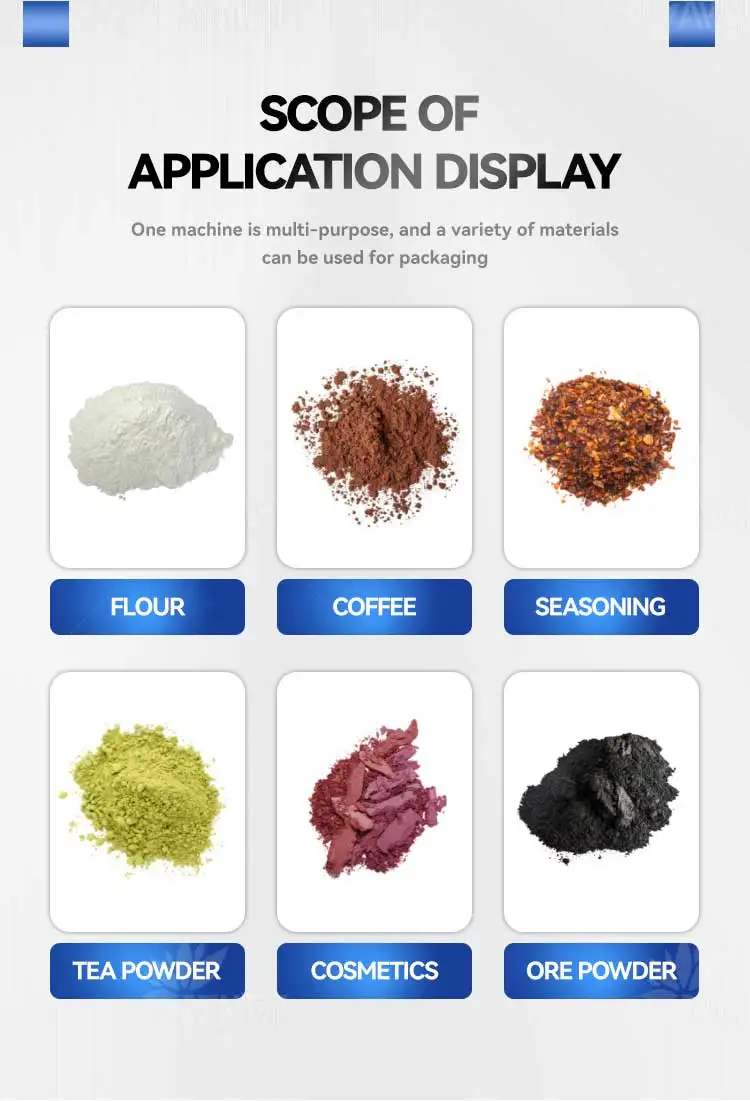

10. Which powder types can this machine handle?

It handles a wide range of free-flowing food powders such as instant coffee, milk powder, sugar, powdered creamer and many spices. Very cohesive, oily or wet powders may require special auger designs, anti-bridging devices or pre-treatment—consult supplier for problematic products.

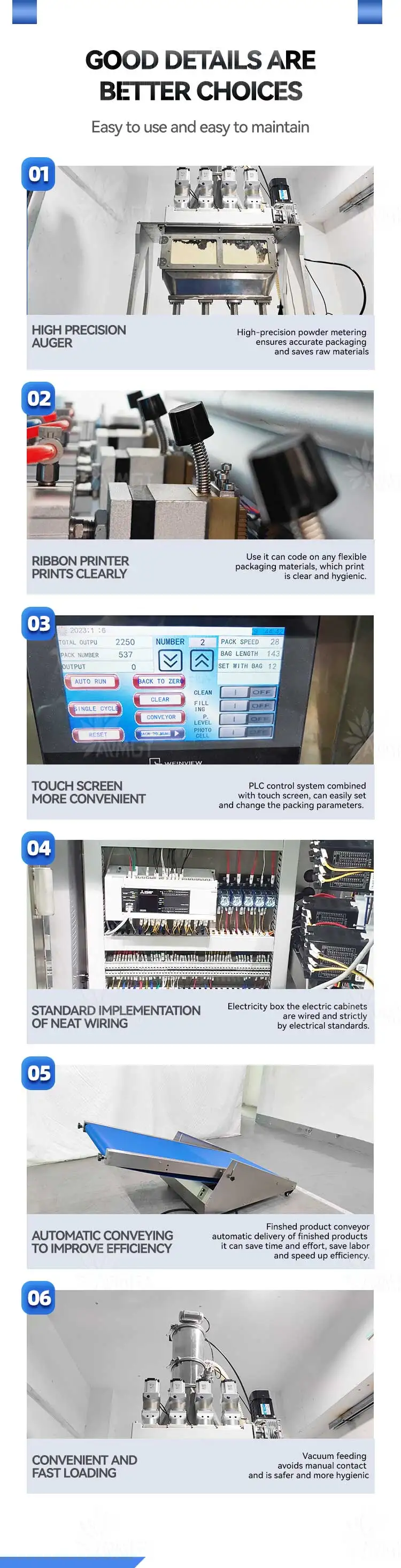

11. What level of dosing accuracy can I expect?

Dosing accuracy depends on the chosen auger type, powder properties (flowability, particle size) and machine settings. The auger systems are intended to achieve precise fills suitable for stick packs; for target tolerances request test runs or samples from the supplier.

12. How long does it take to changeover between sachet sizes?

Changeover time varies by operator skill and the complexity of the size change. Typical changeovers range from about 15 to 60 minutes. Options such as quick-change forming sets or adjustment aids can reduce time—ask about available accessories.

13. What are the recommended cleaning and maintenance practices?

Daily: clean hopper, auger and product-contact surfaces and remove spilled powder. Regularly inspect and replace sealing jaws/blades, belts and bearings as needed. Lubricate moving parts per the maintenance schedule. Follow the manufacturer's maintenance manual for safety and sanitation procedures.

14. Are spare parts, installation, training and warranty available?

Most suppliers provide installation, operator training, spare parts kits and warranty/support packages. Specific terms (length of warranty, spare parts list, lead times) vary—confirm details with the vendor before purchase.

15. Can this machine be integrated with downstream or additional equipment?

Yes. It can typically be integrated with upstream hoppers/feeds and downstream conveyors, checkweighers, date coders/printers, metal detectors and cartoners. Custom options such as hopper agitators, vibrators or special augers are also commonly available—discuss integration needs with the supplier.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading