B21, China Town Mall, Midrand

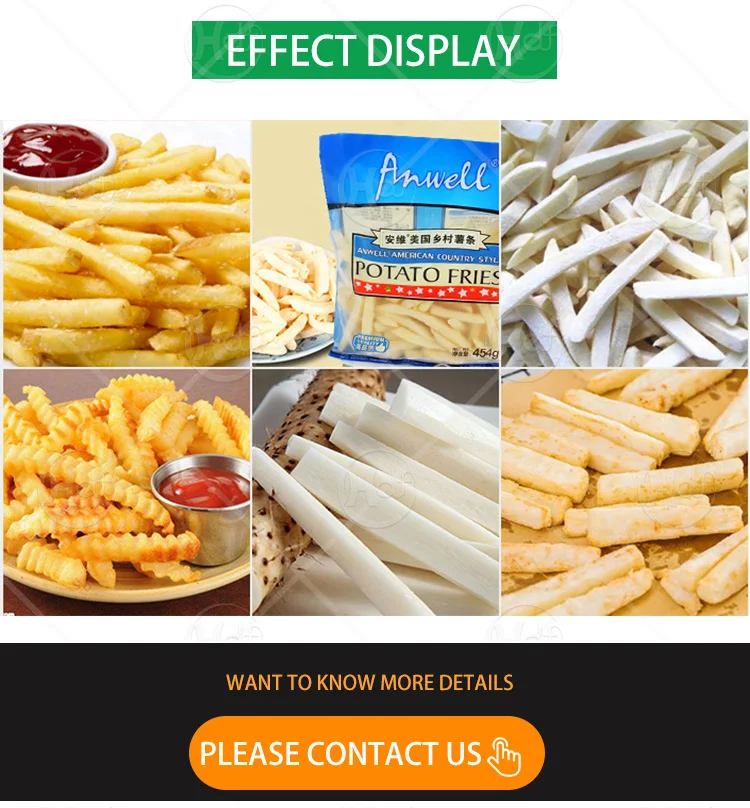

Automatic Potato French Fries Production Line Machine

- Section : Machinery

- Category : Fruit & Vegetable Processing Machines

- SKU : 1600229431297

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the capacity of the Automatic Potato French Fries Production Line?

The production line is designed to handle large-scale production, with specific capacity depending on the model chosen. It can efficiently process several hundred kilograms of potatoes per hour.

2. Is the machine suitable for small businesses?

Yes, the production line offers both fully automated and semi-automatic versions, making it flexible for businesses of various sizes, including small businesses.

3. What types of potatoes can be used?

You can use various types of potatoes to produce French fries, including standard varieties commonly found in markets. The machine is designed to efficiently handle different potato sizes.

4. How does the multi-stage washing system work?

The multi-stage washing system thoroughly cleans the potatoes by removing dirt, debris, and starch through multiple washing phases, ensuring hygiene and quality before peeling.

5. Can the frying temperature be adjusted?

Yes, the integrated frying system allows for adjustable temperature and time settings, enabling you to customize the frying process for optimal crispiness and color.

6. What maintenance does the machine require?

The machine is designed for easy cleaning and maintenance. Regular checks on the peeling, cutting, and frying systems, as well as cleaning the packaging area, are recommended to ensure optimal performance.

7. Does the production line require a lot of space?

The production line features a compact and modular design, allowing it to fit into commercial kitchens or food processing facilities with limited space while still providing large-scale production capabilities.

8. Is training provided for operation of the machine?

Yes, we provide free training for operators to ensure they are fully equipped to operate the machine effectively and safely.

9. How energy-efficient is the production line?

The machine is designed to be energy-efficient, helping to reduce energy consumption while maintaining high output, which can lower overall production costs.

10. What materials are used in the construction of the machine?

The production line is made from high-quality, food-grade materials, ensuring durability, hygiene, and safety in a commercial food processing environment.

11. Can the machine also make potato chips?

Yes, the production line can be utilized to make various products, including potato chips, French fries, plantain chips, yam chips, and cassava chips.

12. What is the warranty period for the machine?

The warranty period typically depends on the specific model purchased. Please refer to the product documentation for detailed warranty information.

13. Is there a customer support service available?

Yes, we offer customer support services to assist with any inquiries, maintenance questions, or troubleshooting needs post-purchase.

14. How does the packaging system work?

The packaging system allows for quick and efficient packaging of finished French fries, streamlining the process from production to sale, especially for businesses that sell frozen or pre-packaged fries.

15. Can I customize the production line according to my needs?

Yes, the production line can be customized to meet specific production needs, including adjustments in capacity, features, and configurations.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading