B21, China Town Mall, Midrand

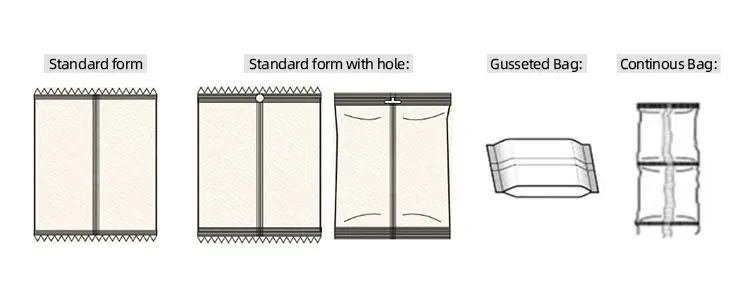

Automatic pillow flow packing candy lollipop protein energy bars chocolate bar horizontal packaging machine

- Section : Machinery

- Category : Laminating Machines

- SKU : 1601091071099

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of products can this packaging machine handle?

The Automatic Pillow Flow Packing Machine is designed to package various solid objects with regular shapes, including food items, pharmaceuticals, daily necessities, hardware, and more.

2. What is the maximum packaging speed of this machine?

The packaging speed of the ZP-500SG model can range from 35 to 300 bags per minute, depending on the product and packaging configuration.

3. What are the packing size dimensions for this machine?

The packing size can accommodate a length of 60 mm to unlimited length, with a width of 30 to 150 mm and a height of 5 to 50 mm.

4. What types of film can be used with this machine?

This machine supports a variety of film types, including OPP, CPP, PT, PE, KOP, and ALU-FOIL.

5. Does this machine have a nitrogen filling function?

Yes, the machine includes a nitrogen filling function, which is beneficial for preserving the freshness of certain products.

6. How does the machine ensure accurate bag length?

The machine features an industry-leading electronic cam algorithm that allows for quick and precise setting of bag length, cutting immediately in one step.

7. What happens if there is no product to package?

The machine is equipped with a 'no product, no bag' function, which prevents the production of empty bags and saves packaging materials.

8. What type of control system does this machine use?

The packaging machine utilizes a 3-servo motor and PLC control system, enhancing the stability and accuracy of operations.

9. Is it easy to set parameters on this machine?

Yes, the machine features a man-machine interface that allows for convenient and quick parameter setting, along with automatic tracking of color codes.

10. What is the total power requirement for this machine?

The total power requirement for the ZP-500SG model is 220V, 50/60HZ, with a total power consumption of 6.3KW.

11. What is the weight and overall size of the machine?

The machine weighs 550 kg and has overall dimensions of 4000 mm in length, 960 mm in width, and 1600 mm in height.

12. Can the machine automatically diagnose faults?

Yes, the machine features an automatic fault diagnosis system that clearly displays any faults for quick identification and resolution.

13. What optional configurations are available for this machine?

Optional configurations include a coding machine, double support paper, automatic film connection, inflation, spray alcohol, lifting panel, and a stainless steel machine body.

14. How does the machine ensure packaging precision?

The machine automatically tracks the feeding speed and adjusts acceleration and deceleration, achieving high speed and precision with an error margin of ±1mm.

15. What is the packaging machine's memory function?

The controller can store various parameter configurations for different products, allowing for quick recall of settings when changing products or packaging films.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading