B21, China Town Mall, Midrand

Automatic Nut Bolt Thread Making Machine with Feeder

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 1600284250172

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

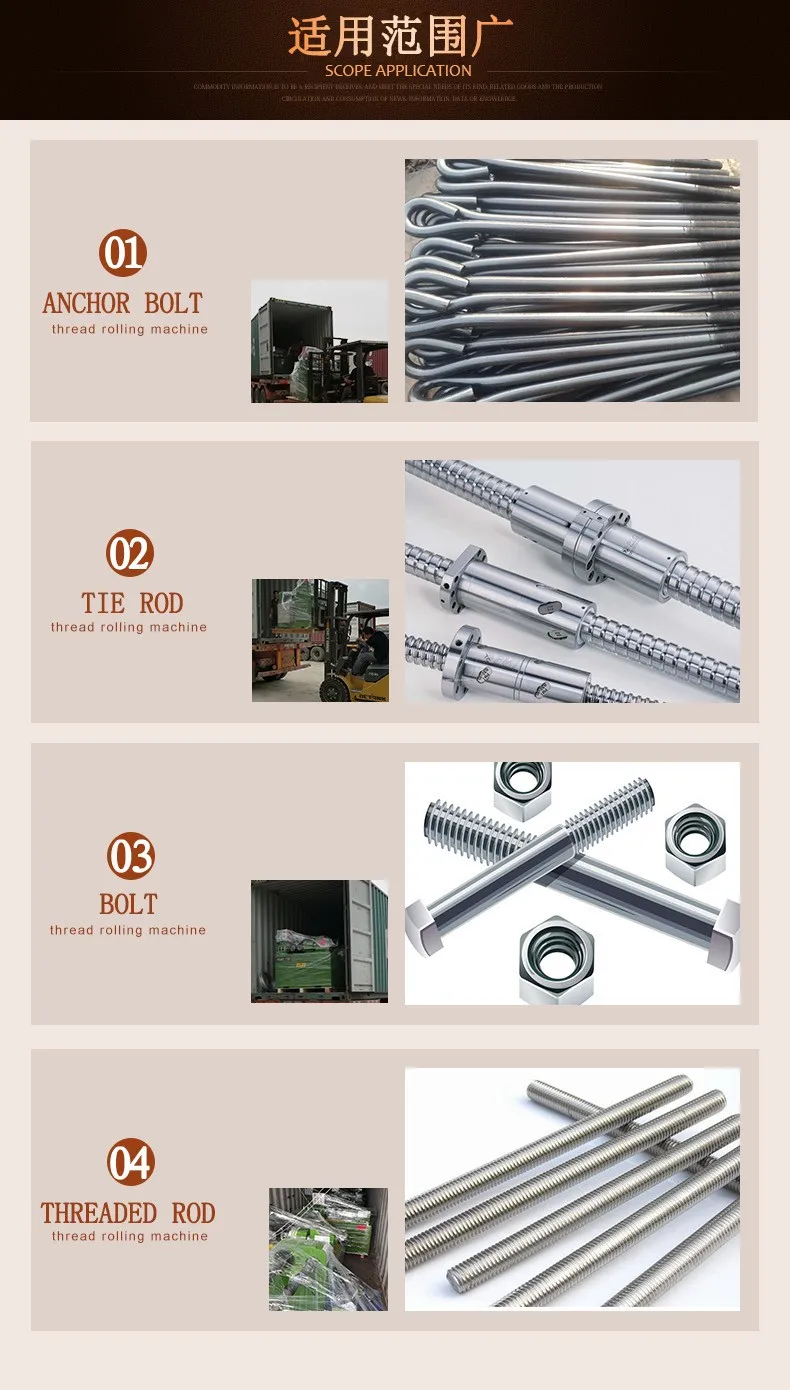

1. What is the Automatic Nut Bolt Thread Making Machine with Feeder (model Z28-185) used for?

The Z28-185 is a rebar thread rolling machine for producing external threads (common threads, trapezoidal threads and modulus threads). It can perform rolling, forming, slide-brading, knurling and related processes on carbon steel, alloy steel and non-ferrous metals.

2. What material and mechanical limits does the machine support?

It is suitable for materials with elongation greater than 10% and within the machine's compressive strength capability (specified in the product data as compressive strength < 100 KGF/mm²). Typical materials include carbon steel, alloy steel and non-ferrous metals.

3. What are the key rolling and thread size specifications?

Rolling diameter range: 6–65 mm. Ordinary pitch range: 1–8 mm. Maximum trapezoidal pitch: 8 mm. Max width of rolling die: 150 mm. Max outer diameter of rolling die: 220 mm. Center distance of die-spindle: 160–280 mm.

4. What are the machine power, force and speed specifications?

Rolling motor: 11 kW. Hydraulic power: 2.2 kW. Cooling motor: 0.12 kW. Max rolling force: 200 kN. Spindle diameter: 75 mm. Spindle tilt angle: ±15°. Spindle speed options: 20/25/31/41/51/64 r/min. Voltage: 208 V, 60 Hz, 3-phase.

5. What does the feeder do and is the machine suitable for long workpieces?

The automatic feeder supplies material continuously to the rolling station for higher consistency and reduced labor. The machine's hollow distribution gear design imposes no theoretical limit on screw length, so very long workpieces can be processed (practical limits depend on support and handling).

6. What certifications and warranty are provided?

The machine is supplied with ISO9001:2008 and CE certifications. Standard warranty is one year, with lifelong technical guidance and support available.

7. What are the machine dimensions and weight?

Host machine dimensions: 1790 × 1620 × 1425 mm. Weight: approximately 2200 kg.

8. How accurate and consistent are the threads produced?

The machine uses hardened alloy rolling wheels and precision-ground sliding parts to improve machining precision. A time relay and automatic feeder improve repeatability and thread consistency. Final accuracy depends on die condition, material and setup.

9. Can the machine be customized for special thread profiles or different die materials?

Yes. Rolling dies are made of hard alloy and can be changed to different grades or profiles on request to match specific thread profiles, materials or production needs.

10. What maintenance is required and what spare parts should I keep on hand?

Regular maintenance includes lubrication of sliding parts, checking hydraulic fluid and filters, inspecting and replacing worn rolling dies, and routine electrical checks. Recommended spare parts: rolling dies, hydraulic seals/filters, bearings and belts. Follow the supplier's maintenance schedule.

11. What site and installation requirements are needed?

Requirements include a stable, level foundation with adequate load-bearing capacity, 208 V 60 Hz 3-phase power supply, proper grounding, sufficient space for material handling and cooling/circuit connections. Detailed installation instructions and support are provided by the supplier.

12. What safety features and operator protections should be used?

The machine should be operated with appropriate guarding around rotating parts, emergency stop controls, and operator PPE (gloves, eye protection, hearing protection). Follow local safety standards and the manufacturer's safety manual. Additional guarding or interlocks can be added on request.

13. What production rate can I expect?

Production rate depends on material, pitch size, thread length and automation level. With the automatic feeder and continuous operation, the machine supports high-volume production—typically tens to hundreds of pieces per hour. Exact cycle times should be determined in a process trial.

14. Does the machine require coolant and how is cooling handled?

Yes — the machine includes a cooling motor (0.12 kW) and provisions for coolant circulation. Use appropriate cutting/rolling fluid as recommended in the manual to extend die life and improve surface finish.

15. What after-sales services and training are available?

Suppliers typically provide one-year warranty service, lifetime technical guidance, operator training, installation assistance and support for spare parts. Confirm specific service levels and response times with your vendor before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading