B21, China Town Mall, Midrand

Automatic Mixed Nuts Snack Sachet Weighing Packaging Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600987814933

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 26 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What products can the Automatic Mixed Nuts Snack Sachet Weighing Packaging Machine package?

The machine is designed for granules and particulate products such as mixed nuts, peanut snacks, candy, candy corn, oatmeal, granola, seeds, dried fruit and similar items. It performs best with free-flowing and partially cohesive granules; special configurations are available for very oily or sticky products.

2. What are the key specifications of the FZ-FS02 model?

Model FZ-FS02 supports 110/220V 50–60Hz power, filling range 20–1000 g (customizable), working speed typically 20–30 bags/min depending on fill volume, roll film width ≤400 mm, bag length ≤280 mm, and overall machine dimensions of 1000×1100×2200 mm.

3. How precise is the weighing and filling system?

The machine uses an advanced weighing device and PLC control for consistent quantitative filling. Actual accuracy depends on product characteristics (size distribution, moisture, stickiness) and selected weighing configuration; we can provide measured accuracy after testing with your product samples.

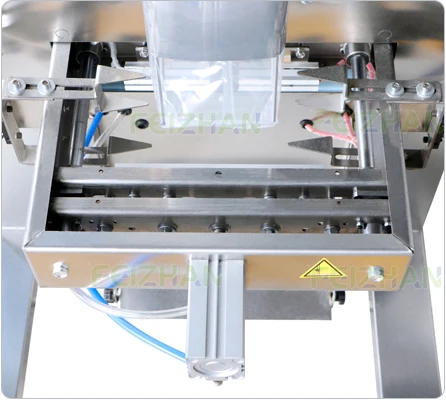

4. What packaging films and bag styles are compatible?

The machine works with heat-sealable roll films (BOPP, PET/PE, PE, CPP, laminated films and similar). It supports three-side and four-side sachet sealing and can be configured for different bag lengths and formats within the stated roll width and bag length limits.

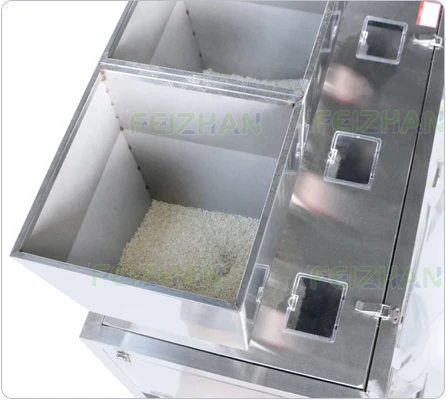

5. Can the machine handle mixed-ingredient packs (different sizes/weights in one bag)?

Yes. The large hopper and precision weighing system are designed to handle mixed ingredients with varied proportions (e.g., mixed nuts and dried fruit). For optimal performance, we recommend sample testing so we can tune the feeding, vibrating, and weighing parameters.

6. How do I change bag length, sealing type, or fill weight?

Bag length and fill weight are adjusted through the PLC control panel and mechanical settings. Sealing type (three-side or four-side) is configured on the sealing module. The PLC interface allows quick real-time adjustments; tooling or die changes may be required for large format changes.

7. What is the typical production speed and what affects it?

Typical speed is 20–30 bags per minute. Actual throughput depends on fill weight, product flow characteristics, film type, and sealing cycle. Lower weights and lighter products generally allow higher speeds; heavier fills and sticky products reduce speed.

8. What safety and control features are included?

The machine features a user-friendly PLC control panel, emergency stop(s), safety guards and covers, fault alarms, and interlocks. Sealing temperature and working parameters are adjustable from the PLC for process control and safe operation.

9. How is cleaning and maintenance handled?

Routine cleaning involves powering down, emptying the hopper, removing and cleaning detachable contact parts (hoppers, funnels, chutes), brushing or blowing out residue, and wiping surfaces. Avoid water on electrical components. Regular maintenance includes checking seals, belts, bearings, lubrication points, and periodic calibration of the weighing system.

10. Can the machine be used for oily nuts or sticky ingredients?

Yes, with appropriate options. Anti-stick coatings, agitators/vibrators, heated or coated feed paths, and customized hoppers can be supplied to improve flow for oily or sticky products. We recommend product samples to determine the best configuration.

11. Does the machine integrate with upstream/downstream equipment?

Yes. The FZ-FS02 can be integrated into production lines with feed conveyors, hoppers, feeders, and downstream conveyors or packing stations. Custom infeed/outfeed interfaces and synchronization options are available on request.

12. What are the power requirements and consumption?

Standard voltage options are 110 V or 220 V at 50–60 Hz. Actual power consumption depends on configuration (heaters, servo motors, additional options) and will be provided for the selected machine specification.

13. What customization options are available?

Customizable items include filling range, number of weighing heads, hopper size, film roll width, bag dimensions, sealing type, anti-stick features, feed vibrators, infeed conveyors, and PLC/software integration. Provide product samples and production targets to get a tailored proposal.

14. What is the lead time, warranty, and spare parts availability?

Lead time depends on customization level; typical delivery for standard configurations is several weeks. Warranty terms and spare-parts packages vary by supplier—please contact us for exact lead time, warranty period and recommended spare parts list for your configuration.

15. How do I request a quote, place an order, or get a product test?

Contact our sales team with your product samples, target fill weights, desired bag size and speed, film type, and any required options. We can provide a quotation, perform sample trials, suggest optimal configuration, and arrange installation, commissioning and operator training as needed.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals