B21, China Town Mall, Midrand

Automatic Grain Processing Rice Whitener Machine For Rice Mill

- Section : Machinery

- Category : Flour & Rice Mills

- SKU : 1601185069613

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the capacity of the Automatic Grain Processing Rice Whitener Machine?

The machine has a processing capacity of 1000-1200 kg of rice per hour, with an input of 1400-1700 kg of paddy per hour.

2. What features are included in the rice milling machine?

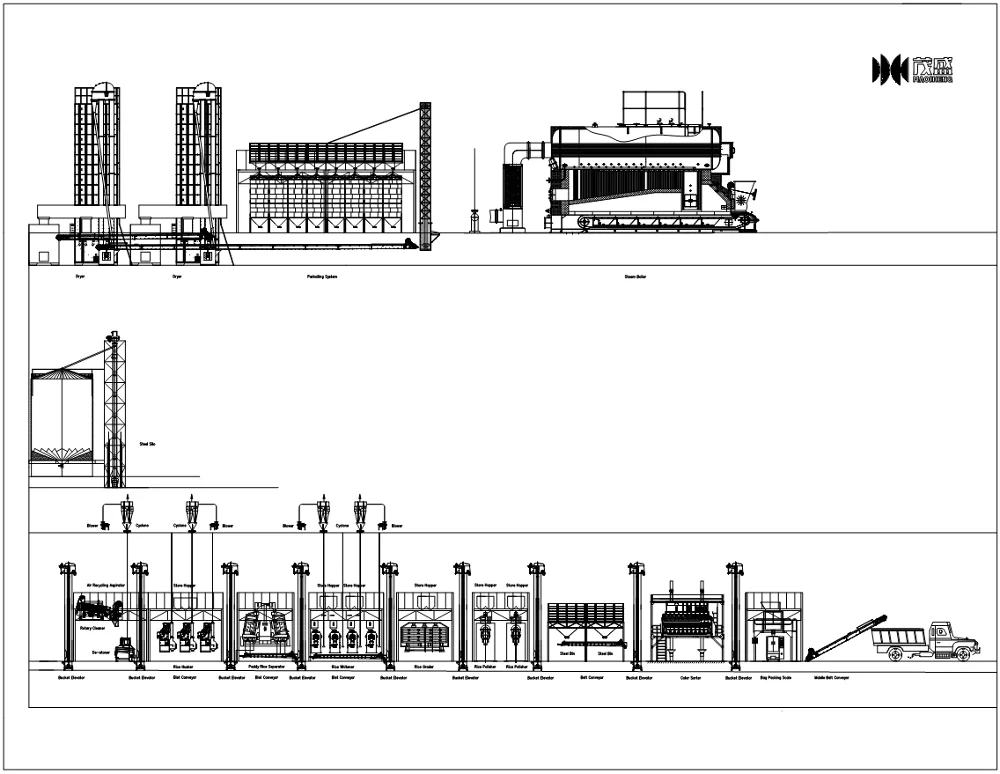

The machine includes a cleaning section, destoner, husking, paddy separating, and milling sections, making it a complete rice processing equipment.

3. Is this machine suitable for small-scale rice milling plants?

Yes, this rice whitener machine is an ideal choice for starting a small-scale rice milling plant due to its efficiency and compact structure.

4. What types of rice can this machine process?

The machine can process both regular and parboiled rice.

5. How does the machine ensure high milling precision?

The machine uses an emery roller that keeps close contact with the rice, producing very few broken grains and ensuring a higher milling rate.

6. What maintenance is required for the rice whitener machine?

The machine is designed for easy maintenance, and regular cleaning and inspection of components like the suction system and rollers are recommended.

7. What is the power requirement for this machine?

The specific power requirement can vary, but it typically operates with a high-power suction system for effective processing.

8. Can the machine operate automatically?

Yes, the Automatic Grain Processing Rice Whitener Machine is designed for automatic operation, streamlining the rice milling process.

9. What advantages does this machine have over traditional milling methods?

The machine offers advantages including low noise, smooth operation, high precision, and a compact structure, which improves efficiency and product quality.

10. Is training available for using the machine?

Yes, training and support are usually provided by the manufacturer to ensure proper use and maintenance of the machine.

11. Where can this machine be used?

This machine is suitable for farms, towns, grain houses, and specialized rice processing households.

12. What type of output quality can be expected from this machine?

The output rice is cleaner, with no rice bran powder, and exhibits a rounder and brighter surface due to advanced processing techniques.

13. What components are included in the whole rice milling line?

The whole rice milling line includes a stone removal machine, husker, gravity paddy separator, high-power suction system, and the emery-roller rice mill.

14. What is the history of the manufacturer?

Hyde Machinery (Maosheng Group) has been manufacturing rice processing equipment since 1976, with extensive experience in the industry.

15. How does the cleaning process work in the machine?

The cleaning process involves several steps, including removing dust, stones, and light grass from the paddy before it moves on to husking and milling.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading