B21, China Town Mall, Midrand

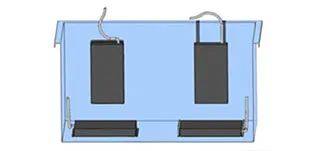

auto parts ultrasonic cleaner car auto parts ultrasound cleaning machine car parts ultrasonic cleaning machine

- Section : Machinery

- Category : Industrial Ultrasonic Cleaners

- SKU : 1601006388881

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is an ultrasonic cleaner?

An ultrasonic cleaner uses high-frequency sound waves to create microscopic bubbles in a cleaning solution, which implode to remove dirt, grease, and other contaminants from various parts.

2. What types of parts can be cleaned with this ultrasonic cleaner?

This ultrasonic cleaner is suitable for various sized metal, plastic, and ceramic parts, making it ideal for automotive components such as injectors, carburetors, and other engine parts.

3. What is the effective tank capacity of the KER-2400 model?

The KER-2400 model has an effective tank capacity of 112 liters (29.6 gallons).

4. Does the cleaner have a heating function?

Yes, each model is equipped with a heating power feature to enhance cleaning efficiency, with varying heating power depending on the model.

5. How does the PLC and HMI control system work?

The PLC & HMI control system allows users to set cleaning parameters easily and choose between automatic and manual operation modes.

6. Is it easy to operate the ultrasonic cleaner?

Yes, the ultrasonic cleaner features a one-touch operation for quick setup and operation, minimizing manual work during the cleaning process.

7. What safety features are included in the ultrasonic cleaner?

The cleaner includes an emergency stop button, a fault and maintenance reminding function, and a liquid level protector for safe operation.

8. Can users perform remote debugging or updates?

Yes, the ultrasonic cleaner has a networking function that allows for remote debugging and PLC program updates.

9. What maintenance is required for the ultrasonic cleaner?

Regular maintenance includes checking the ultrasonic transducers and ensuring the cleaning solution is fresh. The transducer packs can be easily replaced after their lifespan.

10. Is an oil skimmer included with the cleaner?

Yes, the ultrasonic cleaner is equipped with an oil skimmer to help remove oils and greases from the cleaning solution.

11. What are the dimensions of the KER-6000 model?

The KER-6000 model has overall dimensions of 1860x1150x1180 mm.

12. How effective is ultrasonic cleaning compared to traditional methods?

Ultrasonic cleaning is generally more effective than traditional methods, as it can reach small crevices and remove contaminants without damaging the parts.

13. What is the maximum ultrasonic power available in the models?

The maximum ultrasonic power available in the KER series is 12 KW in the KER-4000 model.

14. Can the ultrasonic cleaner be used for anti-corrosive protection?

Yes, the ultrasonic cleaner can be used for anti-corrosive protection during the cleaning process.

15. What optional features are available for the ultrasonic cleaner?

Optional features include a lifting device with up-down-shaking movement function to assist in heavy dirt removal.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading