B21, China Town Mall, Midrand

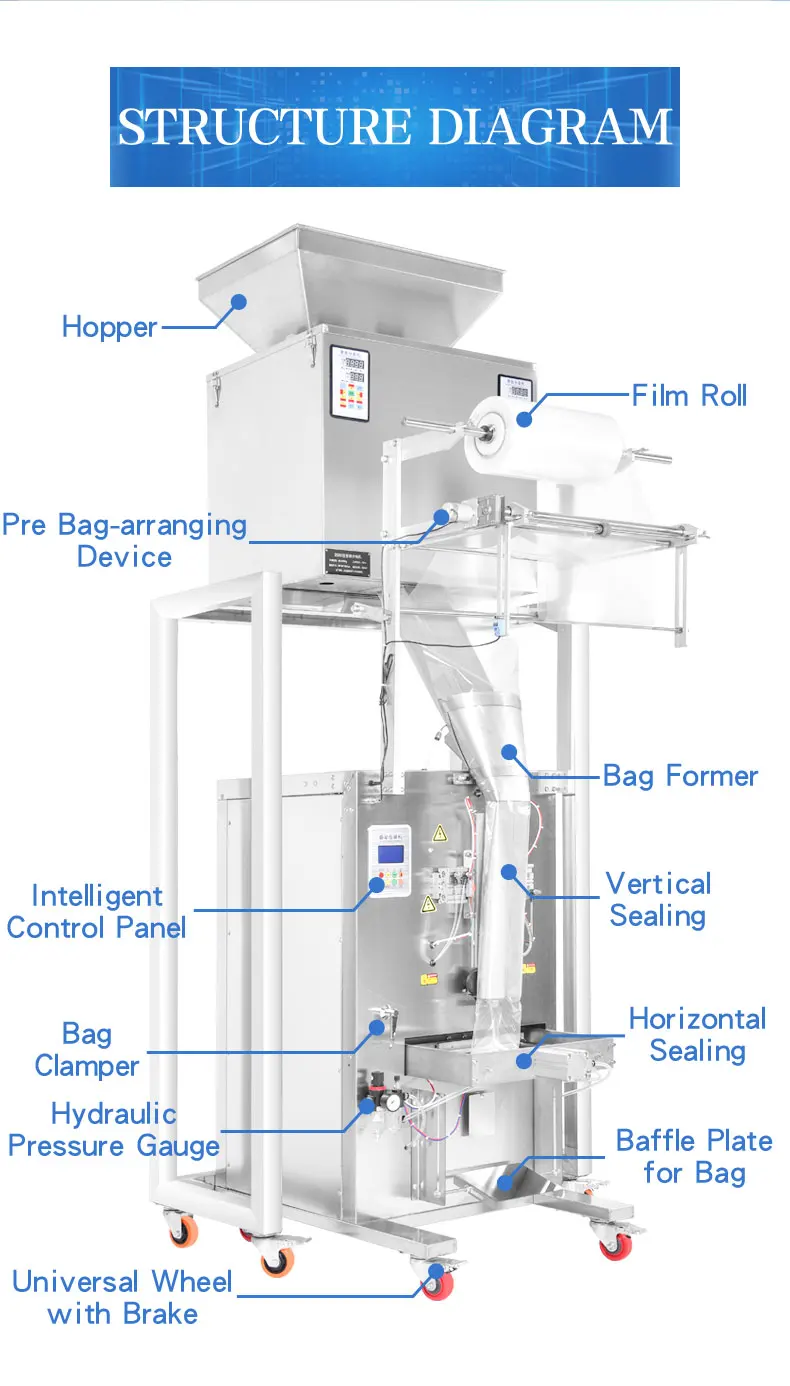

ATE-520 Antai Automatic Packing Machine

- Section : Machinery

- Category : Wrapping Machines

- SKU : 1600593710309

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

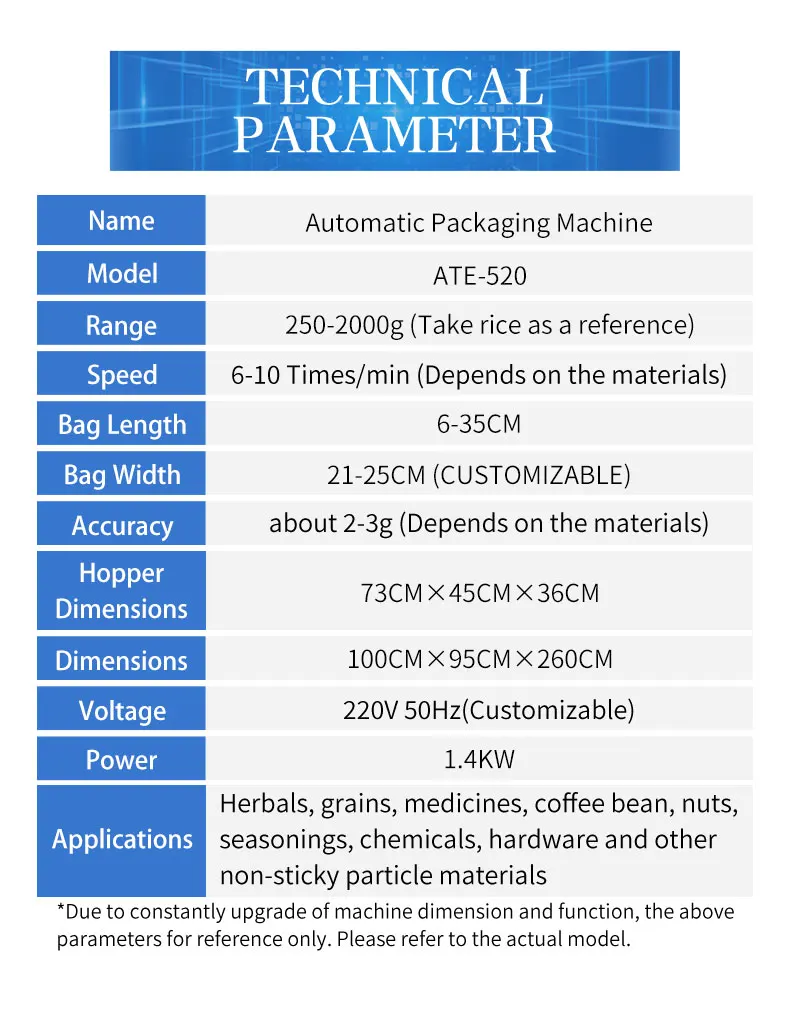

1. What is the ATE-520 Antai Automatic Packing Machine used for?

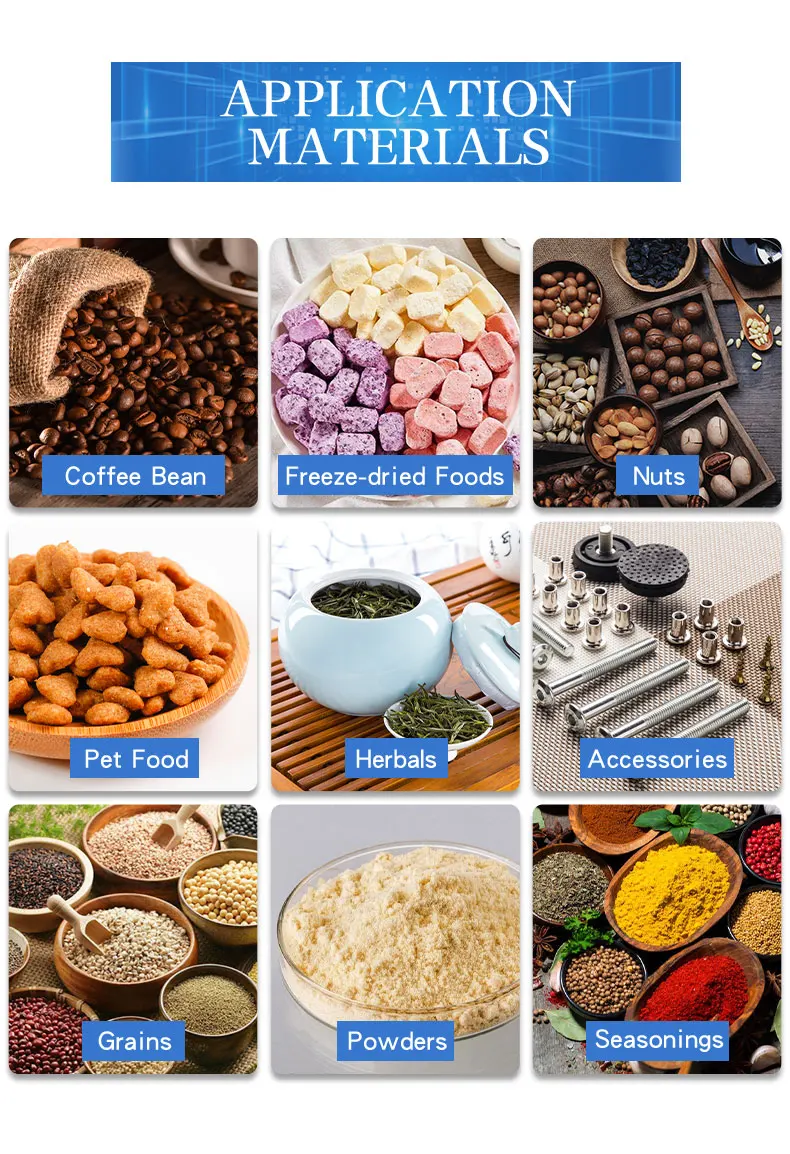

The ATE-520 is an automatic packing machine designed to pack non-sticky particulate products such as rice, grains, coffee beans, nuts, seasonings, herbs, medicines, chemicals and hardware into bags within the specified size and weight ranges.

2. What are the machine's main specifications (size, power, capacity)?

Machine dimensions: 100 cm × 95 cm × 260 cm. Hopper: 73 cm × 45 cm × 36 cm. Power: 1.4 kW. Voltage: 220V/110V, 50/60 Hz (customizable). Filling range: 250–2000 g (rice as reference). Speed: 6–12 cycles/min (material dependent).

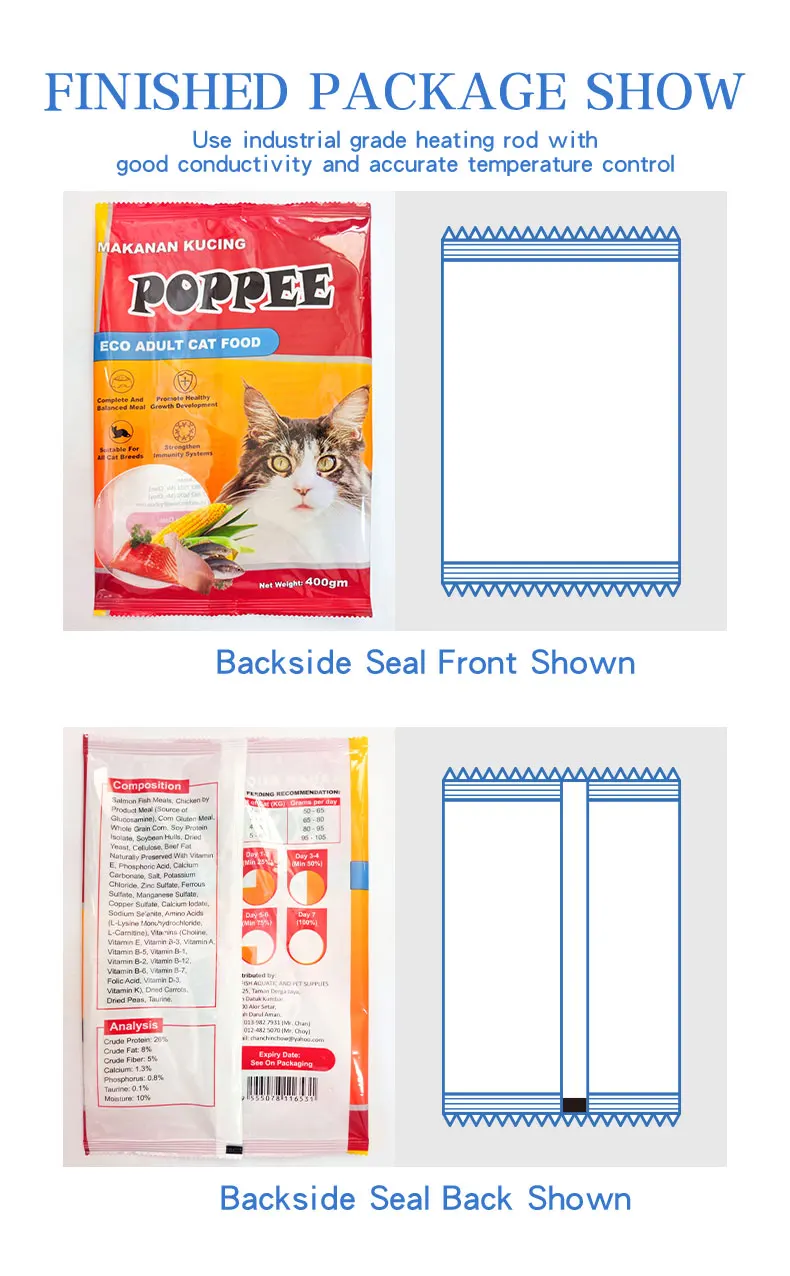

3. What bag sizes does the ATE-520 support?

Bag length: 6–35 cm. Bag width: 21–25 cm (width can be customized). Confirm special bag shapes or sizes with the supplier.

4. What packing accuracy and throughput can I expect?

Typical accuracy is about ±2–3 g, depending on material properties and calibration. Throughput ranges from about 360 to 720 bags per hour at 6–12 cycles/minute; actual throughput depends on bag weight and product handling time.

5. Which materials are suitable or unsuitable for this machine?

Suitable: non-sticky particulate materials (herbals, grains, nuts, coffee, seasonings, small hardware). Unsuitable: highly viscous, strongly adhesive, pasty, or very fine powder that tends to clump unless pre-treated — consult us for difficult materials.

6. Is the ATE-520 noisy? What does 'low noise' mean?

The machine is engineered for low operational noise compared with many industrial packers to improve the working environment. Exact noise levels vary with installation and ambient conditions; contact us for measured dB figures if required for compliance.

7. Can the machine be customized or integrated into my existing line?

Yes. Voltage, some bag dimensions, and control integration can be customized. The machine can be integrated with upstream feeders, conveyors and downstream conveyors or sealing equipment — discuss your line layout with our engineering team.

8. What kind of control system does it use and is operator training required?

The ATE-520 is equipped with PLC-based controls for reliable automatic operation. Basic operator training is recommended and can be provided; the interface is designed for straightforward setup and operation.

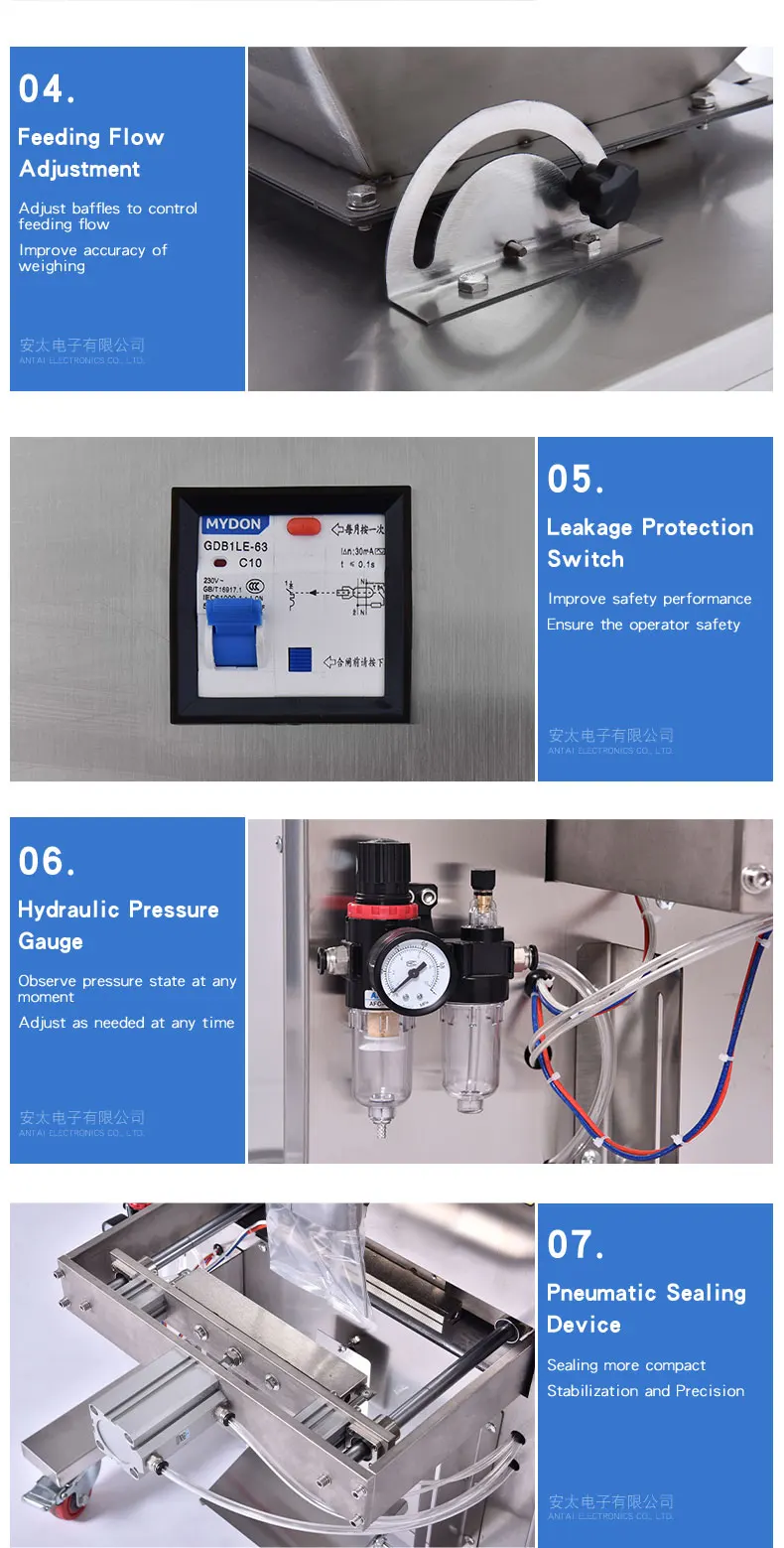

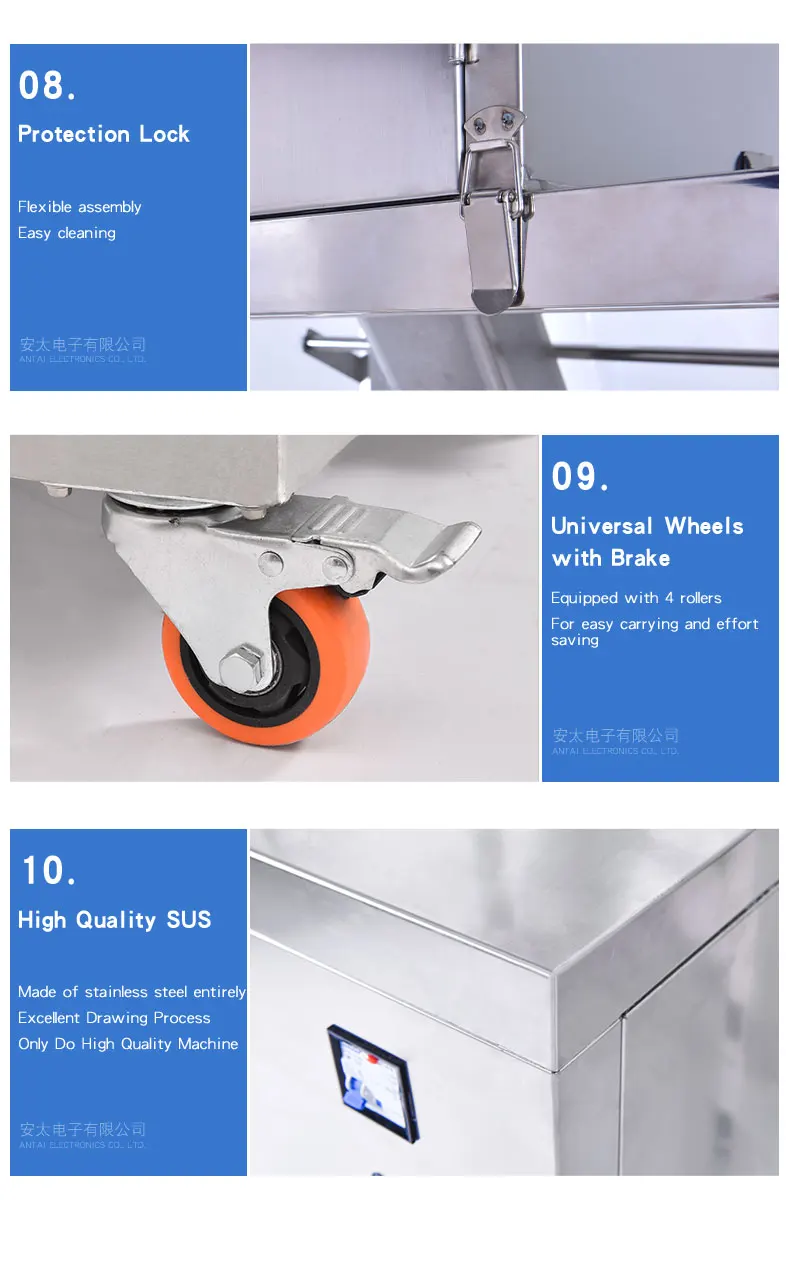

9. What installation requirements are there (space, utilities)?

You need a stable, level floor with sufficient clearance around the machine for operation and maintenance. Utilities: single-phase power per your specified voltage. Some configurations may require compressed air — verify with the supplier at order time.

10. How is maintenance and cleaning handled?

Routine tasks include daily cleaning of product contact areas, periodic inspection and tightening of fasteners, lubrication of gearbox per schedule, and checking electrical connections. Follow the supplied maintenance manual; remote and video technical assistance is available.

11. Do you provide spare parts, service and warranty?

Online support and video technical assistance are offered. Warranty terms and spare-parts availability depend on your purchase agreement — contact sales for warranty length, spare parts kits and service contract options.

12. How do I achieve optimal accuracy with different materials?

Calibrate the machine for each material by adjusting dosing parameters and running test packs. Factors affecting accuracy include particle size, bulk density, flowability and hopper feed. We can provide setup guidance and recommended parameter ranges.

13. Is the machine safe to operate? What safety features are included?

The machine is built with operator safety in mind; it includes standard safety guards and emergency stop functionality. Follow the user manual for lockout/tagout, grounding and safe operation procedures. Additional safety features can be added per local regulations.

14. How can I estimate hourly or daily production in kilograms?

Estimate production by multiplying cycles per minute × minutes worked × average bag weight. Example: at 12 cycles/min and 60 minutes, 720 bags/hour; for 1 kg bags that's 720 kg/hour. Actual figures vary with changeover time and material handling.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading