B21, China Town Mall, Midrand

Anycubic 5X 10X Faster Kobra 2 Max Neo Pro DIY 3D Printer

- Section : Consumer Electronics

- Category : 3D Printers

- SKU : 1600944415012

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Jan, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

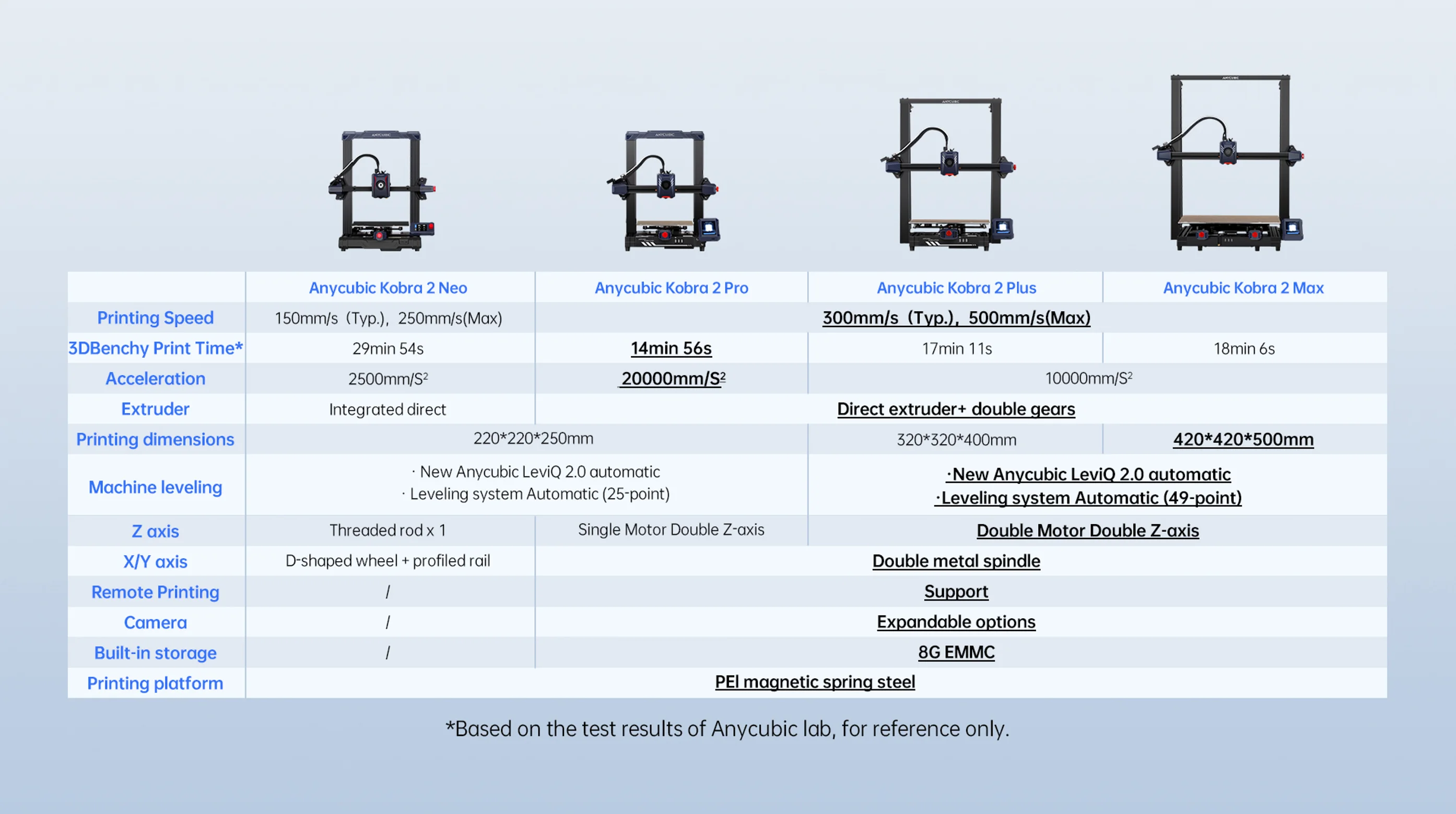

1. What are the maximum build volume and printable dimensions?

The product description lists multiple build-volume figures for closely related models. Common reported dimensions are 350 x 300 x 300 mm (13.8 x 11.8 x 11.8 in) and 245 x 245 x 260 mm (245245260 mm), as well as 25 x 22 x 22 cm in another section. Please check the specific model label or seller product page for the exact build volume of the unit you are purchasing.

2. What printing speeds does this printer support and what speed is recommended?

The printer is capable of very high speeds up to 180 mm/s (≤ 7.1 in/s). For consistent, high-quality results the description recommends printing at 80–100 mm/s.

3. What materials/filaments are supported?

The printer supports common FDM filaments including PLA, TPU, ABS and PETG, and can also print specialty-filled filaments such as wood-filled types. Use appropriate temperature settings for each material.

4. What is the nozzle size and maximum nozzle temperature?

The standard nozzle is 0.4 mm and is replaceable. The maximum nozzle temperature listed is up to 260 °C (≈500 °F).

5. What is the heated bed temperature range?

The hot bed can reach temperatures up to 110 °C (≈230 °F), suitable for materials such as ABS and PETG when bed adhesion is required.

6. Does the printer include automatic leveling?

Yes — the printer supports automatic leveling. The Anycubic LeviQ 25-point precise automatic leveling system is mentioned in the specification list.

7. Is filament run-out detection included?

Filament run-out detection is listed as supported/optional in the description. Confirm with the seller whether the specific unit you receive has the sensor installed or if it is an optional accessory.

8. What control and connectivity options are available?

Connectivity options include a Micro SD card slot for print files and a USB cable (noted as recommended for expert users). Control interfaces vary in the description — either a 4.3" resistive touch screen or a 2.4" LCD with a control knob — so confirm the exact interface on the unit you order.

9. What print resolution and positioning accuracy can I expect?

The printer lists a print resolution of approximately ±0.1 mm. Positioning accuracy is listed as X/Y 0.0125 mm and Z 0.002 mm, which supports precise, detailed printing when using appropriate settings and good calibration.

10. How long does assembly take and is it difficult?

The unit is described as a modular DIY printer designed for quick assembly, with an estimated assembly time of about 10 minutes. Some technical familiarity with basic 3D-printer setup is helpful but the modular design keeps assembly straightforward.

11. Which file formats does the printer support?

The printer accepts common 3D model file formats such as STL, OBJ and AMF. Use a slicer to convert these models to G-code or the file format required by your printer firmware before printing.

12. Which slicer software should I use and what basic settings are recommended?

Any standard slicer that supports FDM printers (Cura, PrusaSlicer, Simplify3D, etc.) will work. Start with a 0.4 mm nozzle profile, layer heights of 0.1–0.2 mm for quality prints, print speeds 80–100 mm/s for a balance of speed and detail, and appropriate nozzle/bed temperatures for your filament.

13. How do I troubleshoot common issues like poor adhesion, stringing, or layer shifts?

Poor bed adhesion: clean bed, level/auto-level, raise first-layer temperature and slow first-layer speed. Stringing: lower nozzle temperature, increase retraction distance/speed in slicer. Layer shifts: check belt tension, ensure pulleys/stepper motors are secure, and reduce printing speed if necessary. Regular maintenance and calibration helps prevent these issues.

14. What maintenance is recommended to keep the printer reliable?

Regular maintenance includes cleaning the nozzle and bed surface, checking and tightening belts and pulleys, lubricating linear rails/lead screws per manufacturer guidance, replacing worn nozzles, and keeping firmware and slicer profiles up to date.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals