B21, China Town Mall, Midrand

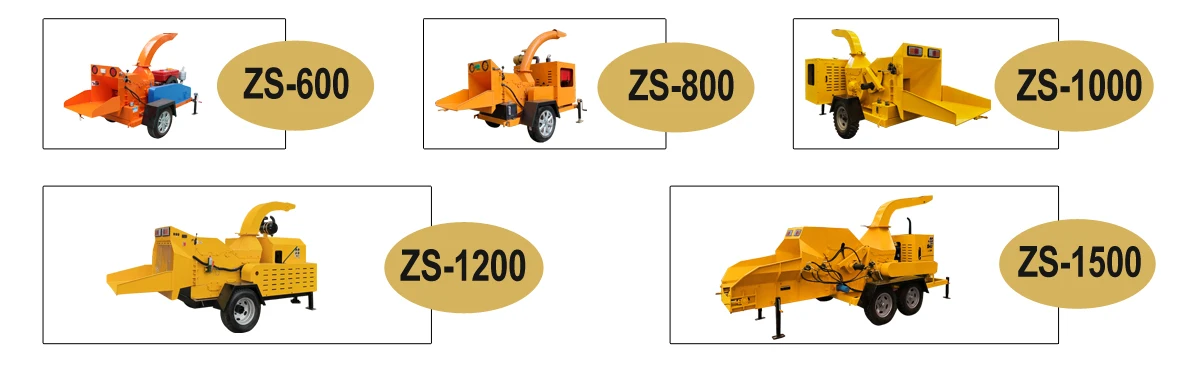

Agricultural Self Feeding Hydraulic Forestry machinery Model: 1063

- Section : Machinery

- Category : Forestry Machinery

- SKU : 1600483879226

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

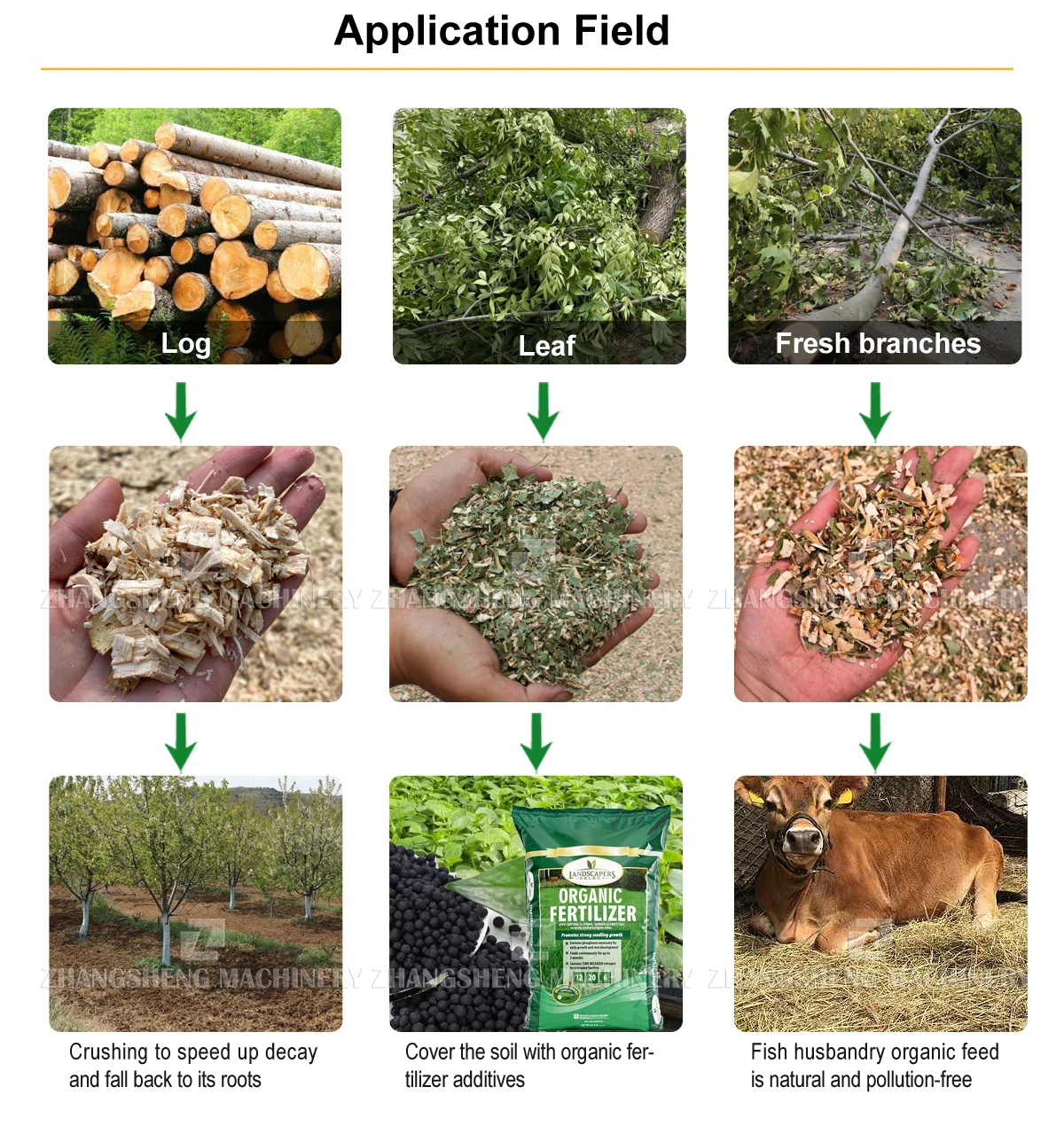

1. What materials can the Agricultural Self Feeding Hydraulic Forestry machine process?

It is designed to cut forestry wood logs, branches, straw and other organic materials for use as mulch, organic fertilizer feedstock or fuel.

2. What is the machine's processing capacity?

Typical capacity ranges from about 4,000–5,000 kg/hour (the 1000 model can reach up to ~5 tons/hour). Actual throughput depends on material type, feed size and model selected.

3. What maximum log diameter can it handle?

Depending on model, the machine can process logs from ~150 mm up to 480 mm. Popular drum models can directly process logs near 300 mm (30 cm) diameter.

4. What chip size does the machine produce?

Finished chip size is generally uniform in the 1–3 cm range, suitable for organic fertilizer production or as fuel.

5. What power options and engine choices are available?

Models are available with diesel engines (examples: 54HP, 102HP, 122HP, 184HP, 235HP, 336HP) and can also be supplied with electric motor options. Engines can be local Chinese brands or premium brands such as Cummins or Perkins. EPA Tier 3/4 compliant engines are available on request.

6. How does the hydraulic feeding system work and what are the benefits?

The hydraulic forced feeding system automatically drives material into the cutting drum with adjustable speed (higher gears increase feed speed and output). It reduces manual feeding, improves safety and lowers the chance of blockages.

7. What anti-jam and safety features are included?

The machine has automatic load monitoring that reduces or stops feeding when load exceeds a set threshold. A manual feed control lever allows forward, reverse and stop actions so operators can clear jams safely.

8. Tell me about the cutting drum and blades.

Cutting drums are large-diameter rotors with high-quality alloy steel blades. Blade counts vary by model (typically 4–9 blades). Blades are hardened for durability and are replaceable when worn.

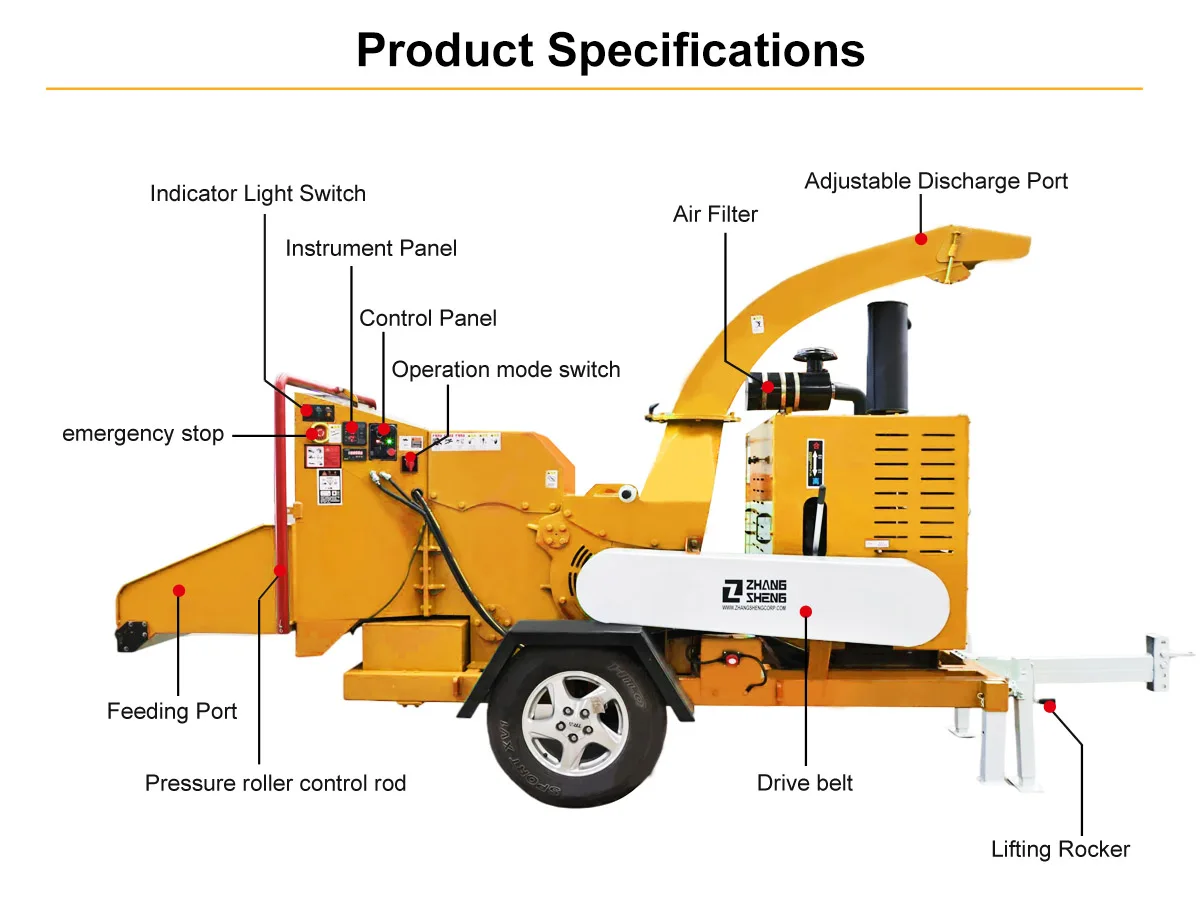

9. How is the chip discharge handled and can I direct the flow?

The discharge chute is 360° adjustable and has a discharge spray distance of about 2.5–3 m, allowing you to direct chips onto trucks, piles or conveyors as needed.

10. Is the machine towable and what are its transport dimensions?

Yes — models come with a 2-inch tow ball and all-steel wheels. A 4-ton unit can be towed by a small car. Overall compact size is around 4250 x 1900 x 2700 mm (may vary by model).

11. What control and monitoring features are provided?

The machine includes a PLC-based intelligent operation panel that displays key parameters (oil volume, water temperature, working hours, etc.) and supports reliable key start for convenient operation and fault finding.

12. What maintenance is required?

Regular maintenance includes inspecting and replacing or sharpening blades when worn, checking and topping hydraulic and engine fluids, lubricating bearings and linkages, inspecting belts and fasteners, and following the engine supplier's service schedule. Keep the feeding area clean and check the PLC alarms regularly.

13. How is the machine packaged and shipped?

Smaller units ship LCL in plywood cases (volumes shown per model). Heavier units may ship in heavy plywood cases with steel framing or in containers depending on size and customer requirements.

14. Can the machine be customized for different applications?

Yes. Different drum sizes, blade counts, engine powers and feed systems are available across model variants. Options such as premium engines (Cummins/Perkins), EPA-compliant engines, and customized discharge or mounting configurations can be discussed with the supplier.

15. What are common applications for this wood chipper shredder?

Typical uses include forestry waste processing, producing raw material for organic fertilizer, biomass fuel preparation, farm and orchard pruning cleanup, and pre-processing material for composting or energy generation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading