B21, China Town Mall, Midrand

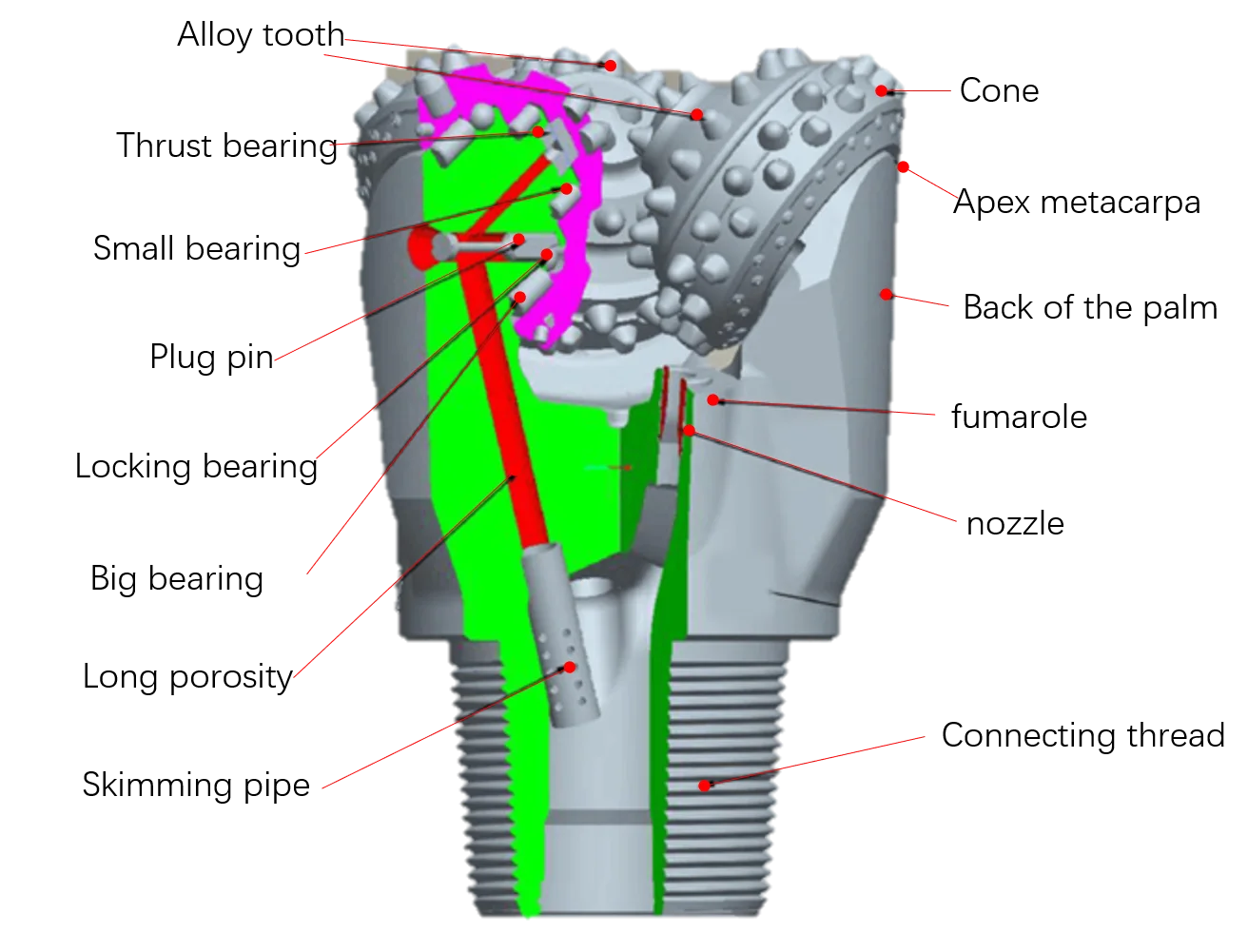

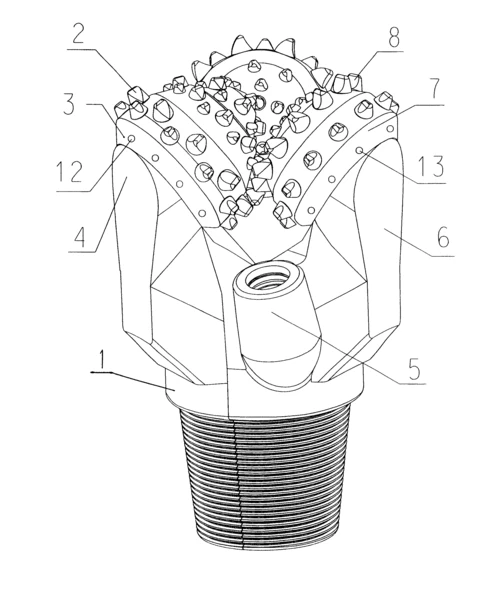

7 1/2 Inch IADC 537 Tricone Drill Bit - Three Cone Rock Roller Bit for Oil Rig and Mining

- Section : Machinery

- Category : Mining Machinery

- SKU : 1601020682530

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 12 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary use of the 7 1/2 Inch IADC 537 Tricone Drill Bit?

The primary use of the 7 1/2 Inch IADC 537 Tricone Drill Bit is for petroleum exploration, mining, geothermal wells, and hydrological surveys.

2. What are the advantages of the carbide teeth on this drill bit?

The carbide teeth are made of high strength and high toughness materials, which improve impact resistance and reduce the rate of broken teeth.

3. Can this drill bit be customized for specific drilling needs?

Yes, our company can provide customized solutions according to the actual drilling situation, including arbitrary diameter assembly drill bits.

4. What materials are used in the construction of this drill bit?

The drill bit features high-strength carbide teeth, a floating bearing structure, high-precision rubber seals, and wear-resistant materials for enhanced durability.

5. What types of formations can this drill bit handle?

The 7 1/2 Inch IADC 537 Tricone Drill Bit is suitable for soft, medium, and hard formations, making it versatile for various drilling applications.

6. What is the operating temperature range for this drill bit?

The drill bit can operate at high temperatures up to 250°C, thanks to its specialized grease designed for high-temperature and anti-wear performance.

7. How does the design of the tooth row enhance drilling performance?

The optimized design of the tooth row, including tooth number, height, and shape, maximizes the drill's cutting ability and speed.

8. What industries commonly use this drill bit?

This drill bit is widely used in industries such as coal mining, petroleum exploration, geological exploration, water conservancy, and construction.

9. What type of sealing system does this drill bit use?

The drill bit uses high-precision rubber seals to ensure optimal sealing and prevent drilling fluid from entering the lubrication system.

10. Is this drill bit effective for drilling in challenging formations?

Yes, the design of the drill bit allows it to cut through challenging formations effectively, improving the drilling level and reducing the risk of damage.

11. What is the expected lifespan of the drill bit?

The lifespan of the drill bit can vary based on the drilling conditions, but the use of wear-resistant materials and optimized designs typically extends its service life.

12. What types of connections are available for this drill bit?

The drill bit features various connecting threads, such as rotary shoulder type external thread connections, which allow for compatibility with different drilling rigs.

13. How does the drill bit ensure effective cooling and cuttings removal?

The drill bit has been designed to optimize cuttings removal and cooling by matching the volume of rock removed by the cutter with the appropriate fluid flow.

14. What additional features does this drill bit offer for lubrication?

The drill bit includes an all-rubber oil storage sac to limit pressure differences and provide effective lubrication for the bearing system.

15. Can this drill bit be used for both oil and water well drilling?

Yes, the 7 1/2 Inch IADC 537 Tricone Drill Bit is suitable for both oil and water well drilling applications.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading