B21, China Town Mall, Midrand

6S Gold Shaking Table 6S Shaker Table Mining Equipment

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600529249431

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the 6S Gold Shaking Table and what is it used for?

The 6S Gold Shaking Table (6S Shaker Table) is a gravity separation concentrator used to separate fine-grained ores by density. It's commonly used in gold, tin, tungsten and other mineral processing to recover fine concentrate, middling and tailings.

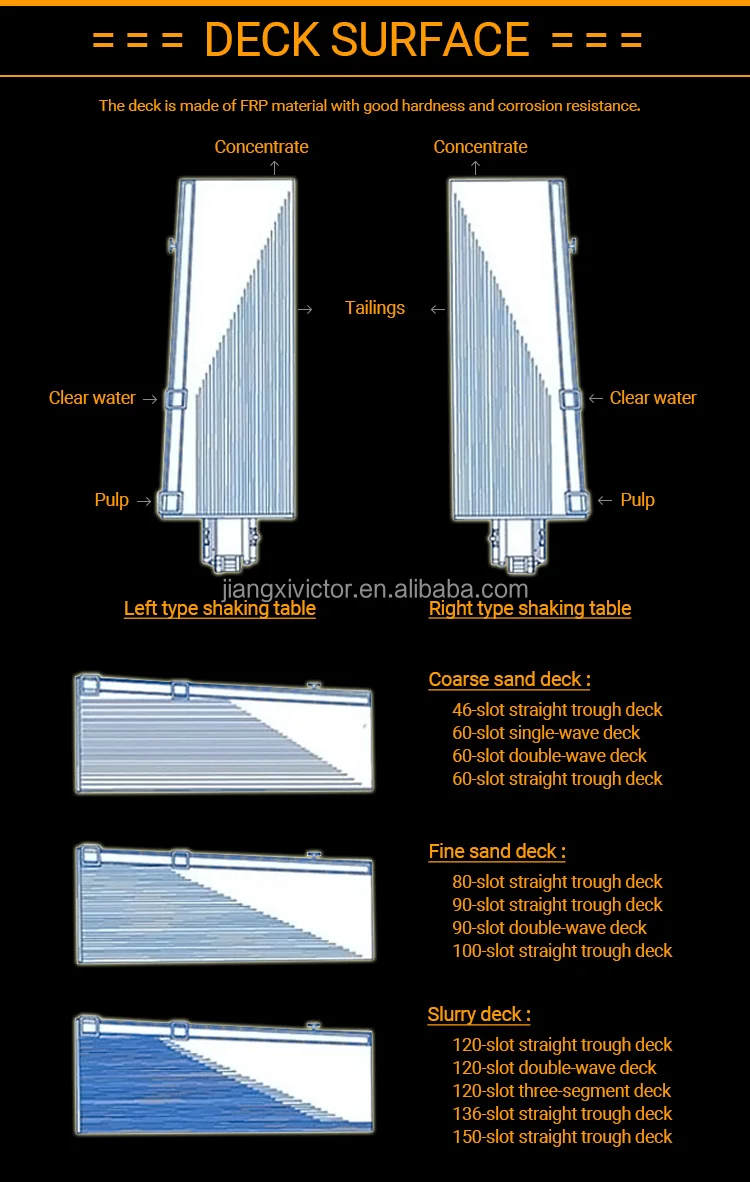

2. What are the main components/features of the shaking table?

Key components include: ore feeding mouth and chute, water feeding mouth and chute, table surface with riffles, stroke adjusting device, swing adjusting device, horizontal support and adjustment wheel, table support and knife-type support, stand, driving unit, motor support and motor, concentrates and tailings discharge areas.

3. How does the shaking table separate materials (working principle)?

Feed and transverse water are introduced onto a riffled table surface. Vibrations create vertical and horizontal motion; particles stratify by density and size and move differently across the riffles. Materials are discharged separately as fine concentrate, middle concentrate and tailings.

4. What models and screen sizes are available?

Available models in the product line: LYS4500 (screen 4500×1850×1560 mm), LYS3000 (3000×1490×1360 mm), LYS2100 (2100×1050×850 mm) and LYS1100 (1100×500×430 mm).

5. What are the stroke length and vibration frequency ranges?

Stroke length and frequency depend on model: LYS4500 stroke 10–30 mm, LYS3000 6–30 mm, LYS2100 12–28 mm, LYS1100 9–17 mm. Frequency ranges are roughly 210–460 T/min depending on model. Exact values are in the specification sheet.

6. What feed particle sizes and densities can this table handle?

The table is designed for fine to coarse feed: commonly effective for particles from about 2 mm down to sub-0.037 mm (different fractions such as 2–0.5 mm, 0.5–0.074 mm, 0.074–0.037 mm). Recommended feeding density is typically 10–30% solids (by weight), depending on ore and model.

7. What is the processing capacity and water consumption?

Capacity varies by model and feed characteristics. Typical coarse and fine (slime) capacities range from fractions of a tonne per hour up to a few tonnes per hour depending on model and feed. Water consumption by model (approximate): LYS4500 0.4–0.7 tph, LYS3000 0.3–1.5 tph, LYS2100 0.2–1.0 tph, LYS1100 0.1–0.5 tph.

8. What motor power is required?

Standard motor power listed for these models is 1.1 kW. Confirm motor specifications at ordering to match local voltage/frequency and drive arrangement.

9. How is the table adjusted for optimal separation?

Adjustments include stroke length and frequency, table incline (horizontal adjustment wheel), feed rate, and water flow. Use the stroke adjusting device, swing adjusting device and horizontal adjustment wheel to tune motion and slope according to ore characteristics to maximize concentrate grade and recovery.

10. What installation requirements should I be aware of?

Install on a stable, level foundation. Provide appropriate power supply for the motor, a controlled water supply and clear access to feeding and discharge points. Ensure the driving unit and motor are securely mounted and align the table level before commissioning.

11. What maintenance is required to keep the table working well?

Regularly inspect the table surface and riffles for wear, check and tighten fasteners, lubricate bearings as recommended, keep the driving unit and motor free of debris, verify water and feed chutes are clear, and replace worn liners/parts promptly to maintain separation performance.

12. What spare parts and consumables should I keep on hand?

Common spare parts include table surface liners/riffles, feed and water chutes, seals, bearings, drive belts or couplings, and replacement bolts. Keep motor and drive component maintenance items on hand per your operating schedule.

13. What safety precautions are recommended when operating the shaker table?

Follow lockout/tagout during maintenance, keep hands and clothing away from moving parts, ensure electrical connections are properly protected and earthed, control water around electrical components, and train operators on safe feed/discharge procedures.

14. How is the product packaged and delivered, and what after-sales support is available?

The product is packaged for transport (details depend on model and order). Delivery terms vary by supplier; check packing pictures and delivery options with the seller. For after-sales support, parts and service, contact the supplier or manufacturer for warranty, spare parts supply and technical assistance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading