B21, China Town Mall, Midrand

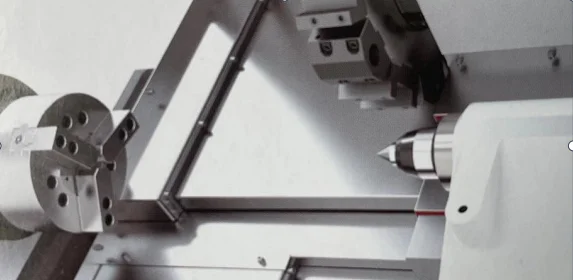

6155E Slant Bed HC Yuhuan Nut Line Automatic Forging Small CNC Lathe Machine

- Section : Machinery

- Category : CNC industrial Machinery

- SKU : 1600572874011

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the 6155E Slant Bed HC Yuhuan Nut Line Automatic Forging Small CNC Lathe Machine?

It is a compact, slant-bed CNC lathe designed for high-throughput production of small turned and forged parts—commonly used in nut-making and similar fastener-manufacturing lines. The machine integrates automatic feeding/forging capabilities with CNC turning for efficient, continuous operation.

2. What does 'slant bed' mean and what are the benefits?

A slant-bed design tilts the bed and guideways to improve chip evacuation and operator access while increasing rigidity and thermal stability. This results in better surface finish, higher accuracy, and easier maintenance compared with vertical or flat-bed designs.

3. Is this machine suitable for automatic forging (cold heading) operations?

Yes—the model name indicates it is intended for automatic forging/nut-line workflows. It can be configured to work with cold-forging or heading operations and synchronized feeding systems, though the exact forging capability depends on the chosen tooling and accessories.

4. What types of materials can the 6155E process?

It typically processes a range of common fastener materials such as low-carbon steel, stainless steel, brass, copper, and aluminum. Material limits depend on tooling, cycle parameters, and any forging equipment used—check with the supplier for material-specific recommendations.

5. What are the typical size limits (max bar diameter and turning length)?

Size limits vary by configuration. As a small CNC lathe for nut/fastener lines, it commonly handles small bar diameters and short turning lengths; exact maximum bar diameter and turning/turn-over length should be confirmed from the machine datasheet or vendor.

6. Which CNC controllers are supported on this machine?

Many suppliers offer mainstream controllers such as FANUC, Siemens, or other popular CNC systems as options. Controller selection is configurable at order and will affect features like program memory, I/O and CNC networking—confirm available controllers with the manufacturer.

7. Does the machine include automation accessories like bar feeders and part catchers?

Yes—this type of machine is normally supplied as part of a nut line with optional or integrated accessories such as bar feeders, chip conveyors, parts catchers, and automated feeding/forging stations. Confirm which accessories are included or available as options.

8. What tooling or turret options are available?

Options typically include multi-station turrets, live tooling for milling/drilling, specialized forging heads, and standard turning holders. The exact tooling configuration is customizable to meet production requirements.

9. What safety features are provided?

Standard safety features usually include full guarding/enclosures, safety interlocks, emergency stop buttons, and operator-safe access doors. Additional safety systems can be added to meet regional regulations and specific plant requirements.

10. What are the power and utility requirements?

Power, air, and coolant requirements depend on the selected configuration and accessories. Exact electrical supply (voltage/phase), pneumatic pressure, and coolant specifications will be provided on the machine's technical datasheet or by the supplier.

11. How accurate and repeatable is the 6155E?

Precision and repeatability depend on machine configuration, controller, tooling, and maintenance. These machines are designed for high-volume, consistent production with repeatability suitable for fasteners; request the manufacturer's accuracy specifications (e.g., position repeatability, surface finish capability) for exact figures.

12. What installation, commissioning and training services are available?

Manufacturers or distributors typically offer on-site installation, commissioning, operator training, and programming support. Remote or factory training sessions may also be available—confirm scope, costs and lead times with your supplier.

13. What maintenance is required and how often?

Routine maintenance includes lubrication of guideways and spindles, coolant and chip management, inspection of tooling and feeding systems, and periodic electrical checks. A recommended maintenance schedule is usually provided by the manufacturer and depends on usage intensity.

14. What warranty and after-sales support are offered?

Warranty terms and after-sales support vary by manufacturer and distributor. Typical offerings include a limited warranty period, spare-parts supply, service contracts, and phone/remote support. Confirm warranty length, coverage, and available service packages before purchase.

15. How can I get detailed specifications, pricing and lead time for this model?

Contact the manufacturer or authorized distributor with your application requirements (part drawings, material, required cycle time, production volume). They will provide a detailed quote, full technical specifications, available options, customization possibilities and estimated lead time.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading